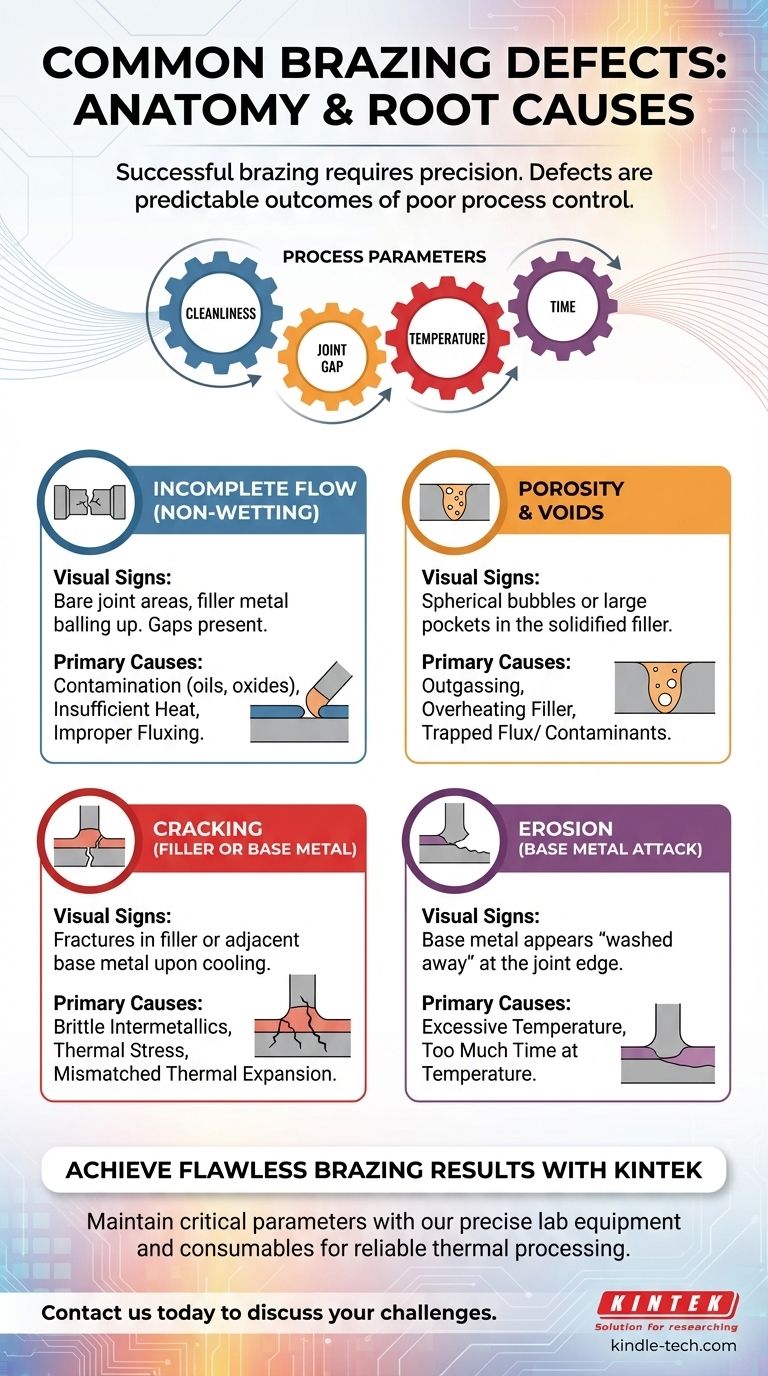

Successful brazing is a process of precision, but when things go wrong, the defects that appear are rarely a mystery. The most common brazing defects include incomplete filler metal flow (non-wetting), porosity or voids within the joint, cracks in the filler or base metal, and erosion of the base material by the filler. These issues almost always trace back to a failure in one of four key process parameters: cleanliness, joint gap, temperature, or time.

The core takeaway is that brazing defects are not random occurrences. They are predictable outcomes of controllable variables. By systematically managing part cleanliness, joint design, heating temperature, and time at temperature, you can eliminate the vast majority of common brazing failures.

The Anatomy of a Brazing Defect

Understanding what a defect looks like is the first step toward diagnosing its cause. Most issues fall into one of a few common categories.

Incomplete Flow or "Non-wetting"

This is arguably the most frequent defect. It occurs when the molten filler metal fails to flow into and fill the entire joint area, leaving gaps and creating a weak bond.

On inspection, you will see areas of the joint interface that are completely bare of filler metal. The filler may have balled up at the point of application instead of being drawn into the gap by capillary action.

This is a classic sign of contamination (like oils or oxides), insufficient heat, or improper fluxing. The filler metal can only bond with a clean, sufficiently hot base metal.

Porosity and Voids

Porosity refers to small, spherical gas bubbles trapped within the solidified filler metal. Voids are larger, irregularly shaped pockets that can be caused by trapped gas or a failure of the filler metal to completely fill the joint.

Both defects act as stress concentrators and reduce the cross-sectional area of the joint, severely compromising its mechanical strength and hermeticity.

Porosity is often caused by outgassing from the base metals, boiling of the filler metal itself if overheated, or gases evolved from reactions with trapped flux or contaminants.

Cracking (Filler or Base Metal)

Cracks are fractures that can appear either in the brazing filler metal as it cools or in the adjacent base metal.

Cracks in the filler metal often indicate that a brittle intermetallic compound has formed or that the joint was subjected to stress during cooling.

Cracks in the base metal are typically caused by thermal shock or stresses induced by mismatched thermal expansion between the two materials being joined. This is a critical concern when brazing dissimilar materials, like steel to copper.

Erosion (Base Metal Attack)

Erosion is the dissolution of the base metal by the liquid filler metal. While some interaction is necessary for a good metallurgical bond, excessive erosion can thin the base material, weakening the assembly.

This defect appears as a "washing away" of the base metal at the joint edge. It is a direct result of either too high a temperature or too much time at the brazing temperature. Certain filler metals are also more aggressive toward specific base metals.

Understanding the Root Causes

Defects are symptoms. To solve them, you must address the underlying cause, which almost always relates back to fundamental process parameters.

The Critical Role of Cleanliness

The single greatest cause of brazing defects is a lack of cleanliness. Brazing relies on an intimate, metal-to-metal connection.

Any surface contaminants—oils, grease, dirt, and especially oxides—will act as a barrier, preventing the filler metal from wetting and bonding to the base material. This is the primary cause of incomplete flow.

The Joint Gap Paradox

Capillary action, the force that draws filler metal into the joint, is highly dependent on the gap between the parts.

An ideal gap is typically very small, often between 0.001" and 0.005" (0.025mm - 0.127mm). A gap that is too small can restrict filler flow, while a gap that is too large will cause the capillary force to break down, resulting in voids or incomplete fill.

Mastering Temperature and Time

Temperature and time are the essential parameters that control the metallurgical reaction.

- Insufficient Temperature: If the base metals are not heated to the filler metal's flow temperature, the filler will not melt and flow correctly.

- Excessive Temperature or Time: As noted in the erosion defect, holding the assembly at temperature for too long or at too high a heat can cause unwanted reactions, base metal erosion, and potentially alter the properties of the base metal (e.g., reduce hardness).

Making the Right Choice for Your Goal

To achieve consistent, high-quality joints, you must shift your focus from fixing defects to preventing them by controlling the process.

- If your primary focus is troubleshooting existing failures: Begin by sectioning and inspecting a failed joint to identify the defect type (e.g., non-wetting, porosity), then audit your pre-cleaning process and temperature validation records.

- If your primary focus is developing a new brazing process: Prioritize designing the joint with a consistent, correct gap and running test coupons to dial in the optimal temperature and time before scaling to production.

- If your primary focus is improving overall quality: Implement rigorous process controls, especially for part cleaning and the method of heating, to ensure absolute consistency from one joint to the next.

Mastering these fundamental principles transforms brazing from a complex challenge into a reliable and repeatable manufacturing process.

Summary Table:

| Defect | Visual Signs | Primary Causes |

|---|---|---|

| Incomplete Flow (Non-wetting) | Bare joint areas, filler metal balling up | Contamination, insufficient heat, improper fluxing |

| Porosity & Voids | Spherical bubbles or large pockets in the joint | Outgassing, overheating filler, trapped flux/contaminants |

| Cracking | Fractures in filler or base metal | Brittle intermetallics, thermal stress, mismatched expansion |

| Erosion | Base metal appears "washed away" at joint edge | Excessive temperature or time at temperature |

Achieve Flawless Brazing Results with KINTEK

Struggling with inconsistent brazing joints or costly rework? KINTEK specializes in the precise lab equipment and consumables necessary for reliable thermal processing. Our solutions help you maintain the critical parameters—cleanliness, temperature, and time—that are essential for defect-free brazing.

Whether you are troubleshooting a persistent issue or developing a new, high-quality brazing process, our expertise can help you improve joint strength, consistency, and yield.

Contact us today to discuss your specific brazing challenges and discover how KINTEK can support your laboratory's success.

Get in touch via our Contact Form

Visual Guide

Related Products

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Graphite Vacuum Continuous Graphitization Furnace

People Also Ask

- Can nitrogen be used for brazing? Key Conditions and Applications Explained

- How we can develop inert atmosphere for a chemical reaction? Master Precise Atmospheric Control for Your Lab

- What is the purpose of inert atmosphere? A Guide to Protecting Your Materials and Processes

- Why nitrogen is used in furnace? A Cost-Effective Shield for High-Temperature Processes

- What provides an inert atmosphere? Achieve Safety and Purity with Nitrogen, Argon, or CO2