After completing your experiment, a systematic shutdown procedure is essential for preserving your sample, maintaining your equipment, and ensuring safety. The correct sequence is to first disconnect the power supply, then carefully disassemble the cell to preserve the working electrode, properly handle the electrolyte solution, and finally, thoroughly clean and dry all components before storage.

Your post-experiment procedure is not merely cleanup; it is a critical phase of the research process. How you handle your sample, cell, and solution directly impacts the validity of your surface analysis, the longevity of your equipment, and the consistency of future experiments.

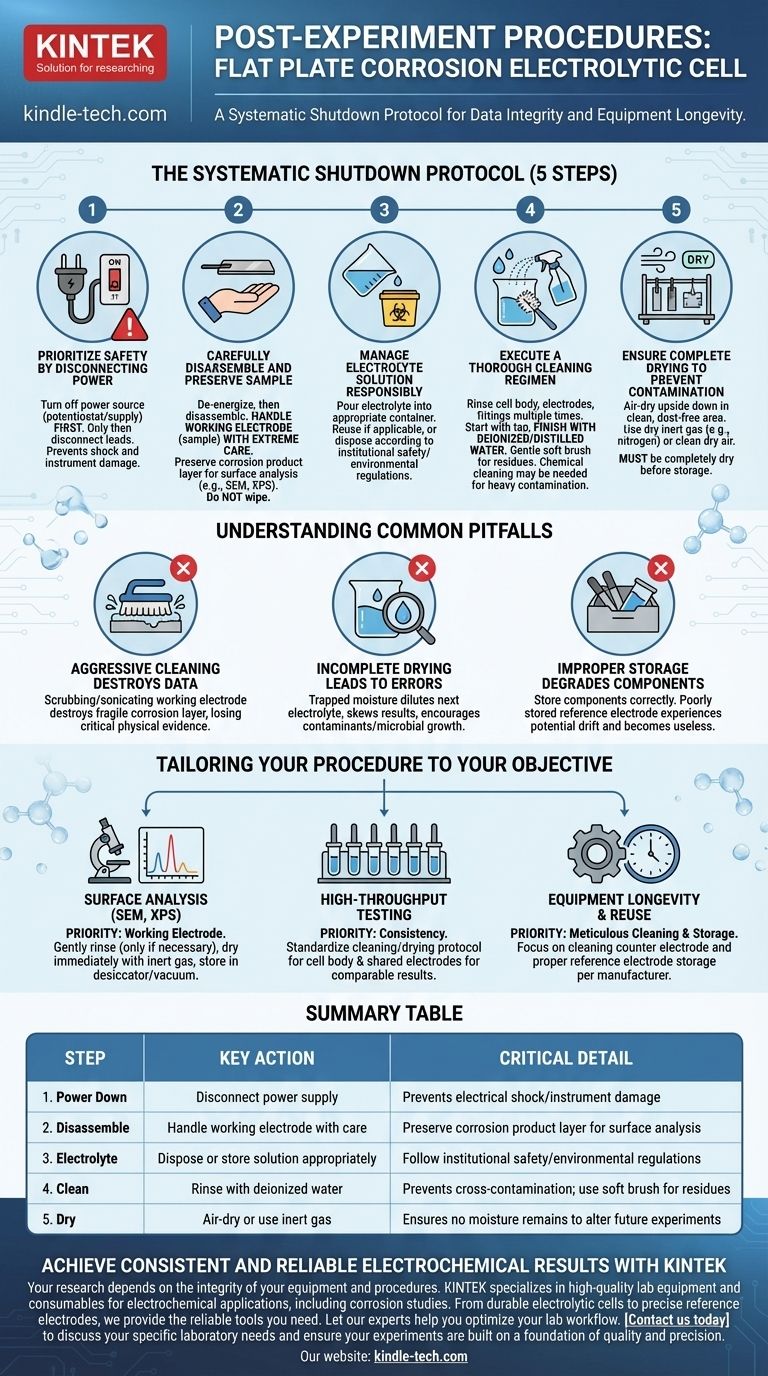

The Systematic Shutdown Protocol

Following a structured protocol prevents damage, contamination, and data loss. Each step serves a specific purpose in transitioning from an active experiment to a state of safe storage.

Step 1: Prioritize Safety by Disconnecting Power

The absolute first step is to turn off the power at the source, such as the potentiostat or power supply. Only after the power is confirmed to be off should you physically disconnect the leads from the electrodes.

This sequence is critical to prevent electrical shock and protect sensitive electronic instruments from potential damage caused by disconnecting a live circuit.

Step 2: Carefully Disassemble and Preserve Your Sample

Once the cell is de-energized, you can begin disassembly. The most critical component is your working electrode (the flat plate sample).

Handle it with extreme care, especially if you plan to perform post-experiment surface analysis like microscopy (SEM) or spectroscopy (XPS). The corrosion product layer that formed during the experiment is a vital piece of data; do not wipe or aggressively rinse it off at this stage.

Step 3: Manage the Electrolyte Solution Responsibly

Pour the electrolyte from the cell into an appropriate container. Your handling method depends on the nature of the solution.

Some solutions may be reusable for a series of experiments. However, most will need to be disposed of according to your institution's safety and environmental regulations, especially if they are hazardous or have been contaminated with dissolved metals.

Step 4: Execute a Thorough Cleaning Regimen

Proper cleaning is essential for preventing cross-contamination between experiments. Rinse the cell body, counter electrode, reference electrode (if robust), and all fittings multiple times.

Start with tap water for initial rinsing, but always perform the final rinses with deionized or distilled water to remove any ions that could interfere with future tests. For stubborn residues, a soft brush may be used on the cell body, but be gentle.

In cases of heavy contamination, a chemical cleaning step—such as soaking the cell body in a dilute acid or base—may be necessary.

Step 5: Ensure Complete Drying to Prevent Contamination

Moisture is the enemy of a clean electrolytic cell. Any residual water can alter the concentration of your next electrolyte or encourage microbial growth during storage.

Air-dry all components by placing them upside down in a clean, dust-free area. For faster results, you can use a gentle stream of dry, inert gas like nitrogen or clean, dry air. Ensure every crevice is completely dry before moving to storage.

Understanding the Common Pitfalls

Even with a protocol, mistakes can happen. Being aware of them is key to generating reliable data.

Pitfall 1: Aggressive Cleaning Destroys Data

The most common error is treating the working electrode like any other piece of glassware. If you scrub or sonicate the sample immediately after the test, you will destroy the fragile corrosion layer.

This layer contains the physical evidence of the corrosion process you just measured. It must be preserved for any meaningful surface characterization.

Pitfall 2: Incomplete Drying Leads to Future Errors

Storing a cell that is even slightly damp is a guarantee of future problems. Trapped moisture can dilute the next electrolyte you use, skewing concentration-dependent results.

It also creates an environment where contaminants from the air can dissolve and adhere to the cell walls, compromising the purity of your next experiment.

Pitfall 3: Improper Storage Degrades Components

Once clean and dry, the components cannot simply be tossed in a drawer. The cell body, typically glass or PTFE, should be stored in a clean, dry cabinet.

Electrodes, especially the reference electrode, require specific storage conditions. A poorly stored reference electrode can experience drift in its potential, rendering it useless for accurate electrochemical measurements.

Tailoring Your Procedure to Your Objective

Your immediate goal after the experiment dictates which steps to emphasize.

- If your primary focus is surface analysis (e.g., SEM, XPS): Your priority is the working electrode. Gently rinse it with deionized water only if necessary to remove bulk electrolyte, then immediately dry it with inert gas and transfer it to a desiccator or vacuum chamber for preservation.

- If your primary focus is high-throughput testing: Your priority is consistency. Develop a standardized and rigorous cleaning and drying protocol for the cell body and shared electrodes to ensure results are comparable from one run to the next.

- If your primary focus is equipment longevity and reuse: Your priority is meticulous cleaning and proper storage of all components. Pay special attention to cleaning the counter electrode and ensuring the reference electrode is stored according to its manufacturer's instructions.

A disciplined and thoughtful post-experiment procedure is the foundation of repeatable and trustworthy electrochemical research.

Summary Table:

| Step | Key Action | Critical Detail |

|---|---|---|

| 1. Power Down | Disconnect power supply | Prevents electrical shock and instrument damage |

| 2. Disassemble | Handle working electrode with care | Preserve corrosion product layer for surface analysis |

| 3. Electrolyte | Dispose or store solution appropriately | Follow institutional safety and environmental regulations |

| 4. Clean | Rinse with deionized water | Prevents cross-contamination; use soft brush for residues |

| 5. Dry | Air-dry or use inert gas | Ensures no moisture remains to alter future experiments |

Achieve Consistent and Reliable Electrochemical Results with KINTEK

Your research depends on the integrity of your equipment and procedures. KINTEK specializes in high-quality lab equipment and consumables for electrochemical applications, including corrosion studies. From durable electrolytic cells to precise reference electrodes, we provide the reliable tools you need.

Let our experts help you optimize your lab workflow. Contact us today to discuss your specific laboratory needs and ensure your experiments are built on a foundation of quality and precision.

Visual Guide

Related Products

- Electrolytic Electrochemical Cell for Coating Evaluation

- Flat Corrosion Electrolytic Electrochemical Cell

- Electrolytic Electrochemical Cell with Five-Port

- PTFE Electrolytic Cell Electrochemical Cell Corrosion-Resistant Sealed and Non-Sealed

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

People Also Ask

- What is the volume range of the coating evaluation electrolytic cell? A Guide to Choosing the Right Size

- What is the difference between electrolytic corrosion cell and electrochemical corrosion cell? Understand the Driving Force Behind Corrosion

- How is a high-precision electrolytic cell used to evaluate metal corrosion resistance? Validate DCT Results Accurately

- How does a three-electrode electrolytic cell function? Precision Testing for 8620 Steel in Corrosive Environments

- What are the advantages of a flat electrochemical cell for corrosion? Achieve Precise Pitting & Crevice Analysis