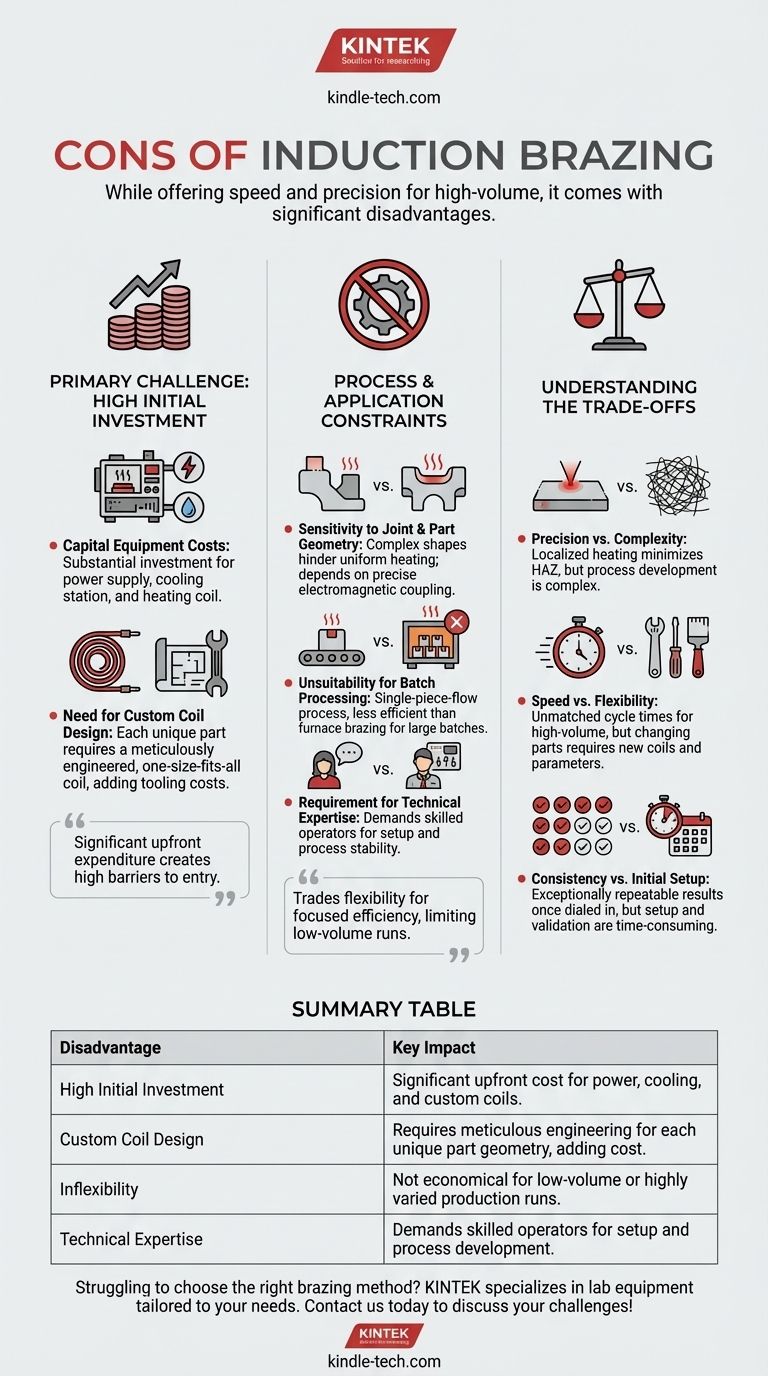

The primary disadvantages of induction brazing are its high initial equipment cost, the necessity for custom-designed coils for each specific joint geometry, and its relative inflexibility for low-volume or highly varied production runs. Unlike methods that heat the entire assembly, induction requires significant upfront engineering to perfect the process for a single, repeatable task.

While induction brazing offers unparalleled speed and precision for high-volume manufacturing, its core cons stem from this very specialization. The process trades the broad flexibility of other methods for focused efficiency, creating high barriers to entry in terms of cost and technical setup.

The Primary Challenge: High Initial Investment

The most significant barrier to adopting induction brazing is the upfront capital expenditure. This cost is not just for one piece of equipment but for an entire integrated system.

Capital Equipment Costs

An induction heating system consists of a power supply, a water-cooling station, and the heating coil or inductor. High-quality, reliable systems represent a substantial investment, often far exceeding the cost of a simple torch or furnace setup.

The Need for Custom Coil Design

The induction coil is the most critical component, as it delivers the energy to the workpiece. It is not a one-size-fits-all tool. Each part and joint configuration requires a meticulously designed coil to ensure precise, uniform heating, which adds significant engineering and tooling costs for every new application.

Process and Application Constraints

Beyond the financial investment, induction brazing has inherent process limitations that make it unsuitable for certain applications.

Sensitivity to Joint and Part Geometry

The success of induction brazing depends entirely on the electromagnetic coupling between the coil and the part. Complex geometries can create challenges in heating the joint area uniformly, potentially leading to incomplete filler metal flow or localized overheating.

Unsuitability for Batch Processing

Induction is typically a single-piece-flow process. While extremely fast per part, it cannot match the efficiency of furnace brazing for processing large batches of assemblies simultaneously. This makes it less economical for jobs with a high mix of different parts in low quantities.

Requirement for Technical Expertise

Developing a stable and repeatable induction brazing process requires a higher level of technical skill than manual methods. Operators and engineers must understand power settings, frequency, heating times, and coil design to achieve consistent, high-quality joints.

Understanding the Trade-offs: Induction vs. Other Methods

Choosing induction brazing means accepting a specific set of compromises. Understanding these trade-offs is key to making an informed decision.

Precision Heating vs. Minimized Component Stress

A key advantage of induction is its localized heating, which creates a very small heat-affected zone (HAZ). This minimizes the risk of annealing or distorting the rest of the component—a common downside of furnace brazing where the entire assembly is heated. However, this precision comes at the cost of process development complexity.

Speed vs. Flexibility

For a dedicated, high-volume production line, induction's cycle times (often just a few seconds) are unmatched. This speed, however, is directly tied to its inflexibility. Changing to a different part requires new coils and process parameters, whereas a skilled operator with a torch can switch between different jobs with ease.

Consistency vs. Initial Setup

Once dialed in, an induction process delivers exceptionally consistent and repeatable results, reducing operator error. This reliability is earned through a rigorous and often time-consuming setup and validation phase, which is not required for more manual brazing methods.

Making the Right Choice for Your Application

To determine if induction brazing is appropriate, you must align its characteristics with your primary production goals.

- If your primary focus is high-volume, repeatable production: The speed and consistency of induction brazing will likely provide a strong return on the high initial investment.

- If your primary focus is low-volume runs or a wide variety of parts: The high cost of custom tooling and setup for each part makes torch or furnace brazing a more practical and cost-effective choice.

- If your primary focus is metallurgical integrity and minimizing heat distortion: Induction's precise, localized heating offers a significant advantage over methods that heat the entire assembly.

Ultimately, selecting the right brazing method requires a clear understanding of where you are willing to accept complexity in exchange for performance.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| High Initial Investment | Significant upfront cost for power supply, cooling, and custom coils. |

| Custom Coil Design | Requires meticulous engineering for each unique part geometry, adding cost. |

| Inflexibility | Not economical for low-volume or highly varied production runs. |

| Technical Expertise | Demands skilled operators for setup and process development. |

Struggling to choose the right brazing method for your lab's production needs?

The cons of induction brazing—like high costs and inflexibility—highlight the importance of selecting the right equipment for your specific application. At KINTEK, we specialize in providing lab equipment and consumables tailored to your unique requirements. Whether you're focused on high-volume consistency or low-volume flexibility, our experts can help you find the perfect solution to maximize efficiency and ROI.

Contact us today via our [#ContactForm] to discuss how we can support your laboratory's brazing and thermal processing challenges!

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Double Plate Heating Press Mold for Lab

- Anti-Cracking Press Mold for Lab Use

- Small Injection Molding Machine for Lab Use

People Also Ask

- Do you need to autoclave glassware? A Guide to Sterilization vs. Cleaning

- Can autoclave sterilize liquid? Master Safe and Effective Liquid Sterilization

- What temperature must be reached for sterilization in 10-12 minutes? Achieve Rapid, Reliable Sterility with Flash Autoclaving

- What are the advantages of autoclaving in hospitals? Achieve Unmatched Sterilization for Patient Safety

- What is the use of autoclave in medical? The Critical Role of Sterilization in Patient Safety