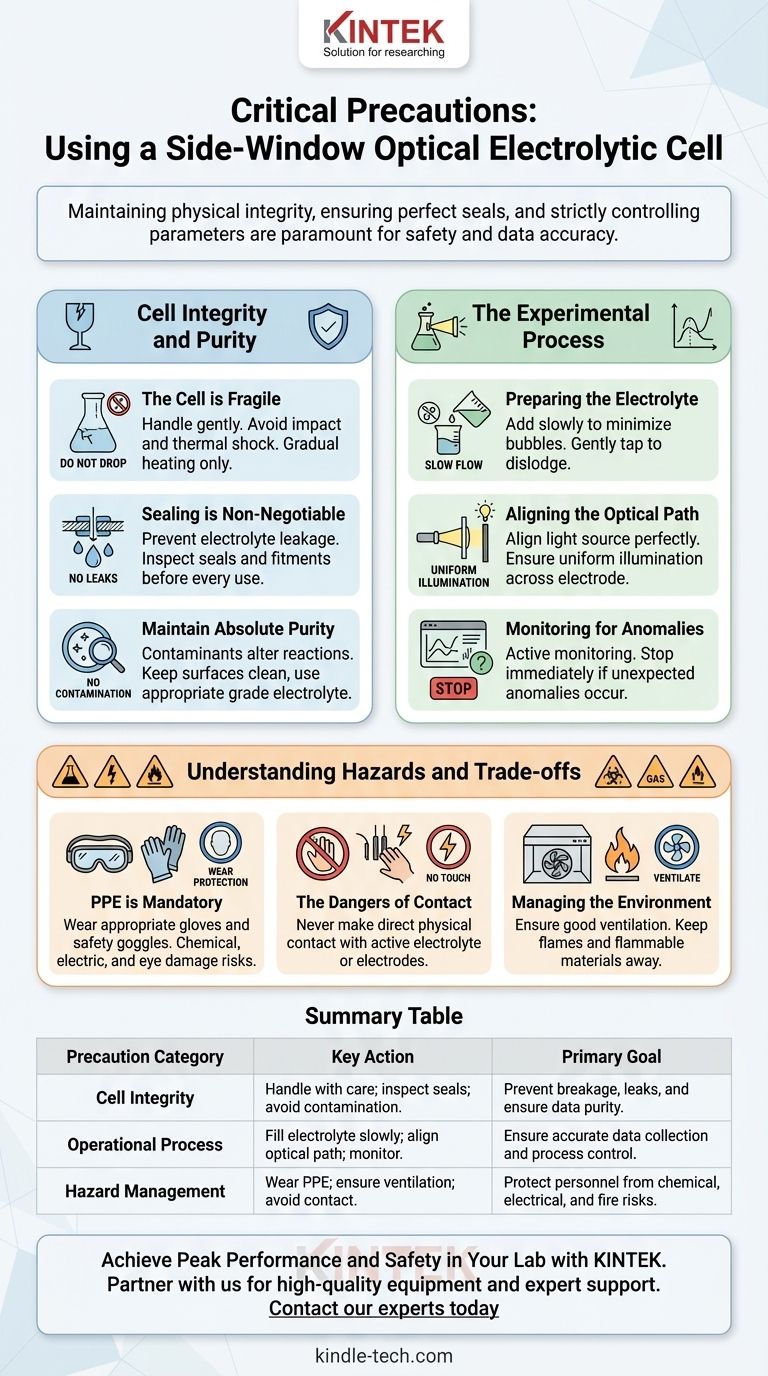

The most critical precautions for using a side-window optical electrolytic cell involve three core areas: maintaining the physical integrity of the fragile cell, ensuring a perfect seal to prevent electrolyte leakage, and strictly controlling experimental parameters like temperature, concentration, and optical alignment to ensure both safety and data accuracy.

This specialized equipment combines chemical, electrical, and optical hazards within a delicate glass or quartz body. Therefore, your experimental procedure and your safety protocol are fundamentally linked; neglecting one will inevitably compromise the other.

Foundational Principles: Cell Integrity and Purity

The reliability of your experiment begins with the physical state of the cell itself. Before any electrical or chemical processes start, you must ensure the vessel is sound.

The Cell is Fragile: Handle with Care

The cell body is made of glass or quartz, materials that are brittle and susceptible to breakage from physical shock or thermal stress.

Always handle the cell gently. Avoid any impact with hard objects, and when heating is required, ensure it is done gradually to prevent cracking.

Sealing is Non-Negotiable: Prevent All Leaks

Electrolyte leakage is a primary failure point. It compromises experimental results, poses a chemical hazard to you, and can damage surrounding equipment.

Before every use, inspect the seals. Ensure all components are fitted correctly and tightly to create a leak-proof system.

Maintain Absolute Purity: Avoid Contamination

The accuracy of electrochemical measurements depends on the purity of the system. Contaminants can alter the reaction you intend to study.

Prevent any impurities from entering the cell. Keep the cell surfaces clean and ensure the electrolyte used is of the appropriate grade.

The Experimental Process: From Setup to Measurement

Correct operational procedure is essential for gathering meaningful data and ensuring the experiment runs as intended.

Preparing the Electrolyte: Slow and Steady

When filling the cell, add the electrolyte slowly and carefully through the designated opening.

This minimizes the formation of bubbles, which can interfere with both the optical path and the electrochemical process. If bubbles do appear on the electrode or window, gently tap the cell to dislodge them.

Aligning the Optical Path: The Key to Good Data

The defining feature of this cell is its optical window. Proper alignment of the light source is not optional—it is critical for valid results.

Position your light source so it aligns perfectly with the side window. Adjust the optical system to ensure the light provides uniform illumination across the entire surface of the working electrode.

Monitoring for Anomalies: Be Ready to Stop

An experiment is an active process. Do not "set it and forget it."

Closely monitor your instrument data, curves, and any physical changes in the cell. If you observe any unexpected anomalies, stop the experiment immediately to diagnose the issue.

Understanding the Hazards and Trade-offs

Using an electrolytic cell means managing inherent risks. Understanding these potential failures is key to preventing them.

Personal Protective Equipment (PPE) is Mandatory

There is no substitute for proper protection. The risks of chemical burns, electric shock, and eye damage are real.

Always wear appropriate gloves and safety goggles, especially when handling the electrolyte and connecting the electrodes.

The Dangers of Contact: Chemical and Electrical Hazards

Never make direct physical contact with the electrolyte or the electrodes during operation.

These components can cause severe chemical burns or deliver a dangerous electric shock. Treat the entire active setup as a hazard zone.

Managing the Environment: Ventilation and Fire Prevention

Electrolysis can produce harmful gases or excessive heat. A closed, stagnant environment concentrates these dangers.

Ensure your workspace has good ventilation. Furthermore, keep all open flames or flammable materials far away from the cell to eliminate the risk of fire or explosion.

Making the Right Choice for Your Goal

Your primary focus will determine which precautions demand the most attention.

- If your primary focus is data accuracy: Prioritize the prevention of contamination, precise control of temperature and concentration, and perfect alignment of the optical path for uniform illumination.

- If your primary focus is personal and lab safety: Your non-negotiables are wearing appropriate PPE, ensuring a leak-proof seal, maintaining proper ventilation, and avoiding all direct contact with active components.

- If your primary focus is extending the cell's lifespan: Handle the cell with extreme care to avoid physical shock, perform gradual temperature changes, and conduct regular inspections of seals and wiring.

Ultimately, a successful experiment is one that is both safe and produces reliable data; these goals are achieved through the same disciplined approach.

Summary Table:

| Precaution Category | Key Action | Primary Goal |

|---|---|---|

| Cell Integrity | Handle with care; inspect seals; avoid contamination. | Prevent breakage, leaks, and ensure data purity. |

| Operational Process | Fill electrolyte slowly; align optical path; monitor for anomalies. | Ensure accurate data collection and process control. |

| Hazard Management | Wear PPE (goggles, gloves); ensure ventilation; avoid contact with active components. | Protect personnel and lab from chemical, electrical, and explosion risks. |

Achieve Peak Performance and Safety in Your Lab

Properly handling specialized equipment like side-window optical electrolytic cells is fundamental to obtaining accurate results and protecting your team. KINTEK understands the critical balance between precision and safety in laboratory environments.

We specialize in providing high-quality lab equipment and consumables tailored to your specific research needs. Whether you are setting up a new experiment or optimizing an existing protocol, our expertise can help you enhance efficiency and ensure compliance with the highest safety standards.

Let KINTEK be your trusted partner in laboratory excellence. Contact our experts today to discuss your requirements and discover how our solutions can support your groundbreaking work.

Visual Guide

Related Products

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Electrolytic Electrochemical Cell with Five-Port

- H Type Electrolytic Cell Triple Electrochemical Cell

- Thin-Layer Spectral Electrolysis Electrochemical Cell

- PTFE Electrolytic Cell Electrochemical Cell Corrosion-Resistant Sealed and Non-Sealed

People Also Ask

- How should the H-type electrolytic cell be stored when not in use? Expert Storage & Maintenance Guide

- What is the typical experimental system used with a double-layer water-bath electrolytic cell? Achieve Precise Electrochemical Control

- What is the purpose of the double-layer structure in the H-type electrolytic cell? Achieve Precise Thermal Control

- What optical features does the H-type electrolytic cell have? Precision Quartz Windows for Photoelectrochemistry

- What is a H type cell? A Guide to Divided Electrochemical Cells for Accurate Experiments