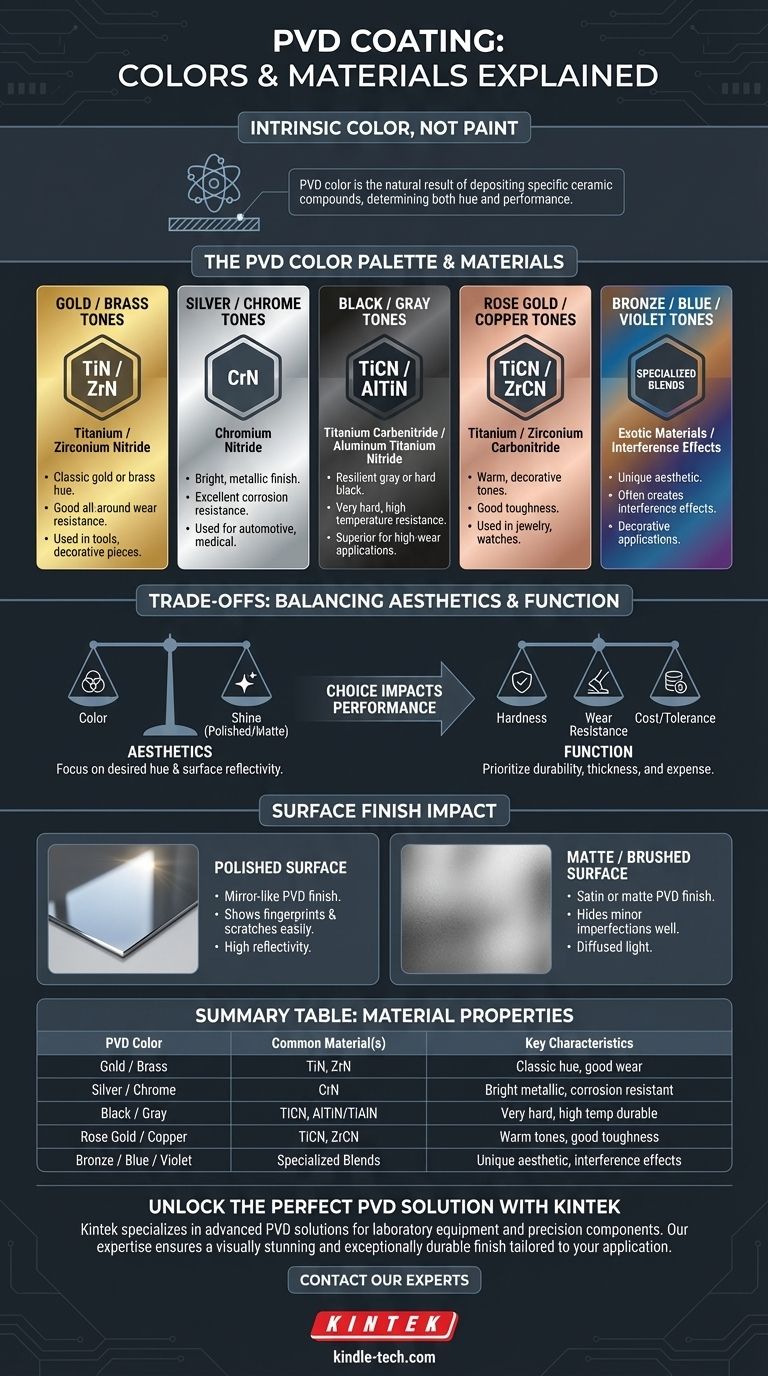

In short, PVD coatings come in a wide spectrum of colors, including gold, rose gold, black, gray, bronze, blue, and chrome-like silver. Unlike paint, these colors are not dyes but are the intrinsic result of depositing specific ceramic compounds onto a surface in a vacuum, which also determines the coating's durability and performance.

The key is to understand that PVD color is not just a cosmetic layer; it is a direct function of the material being deposited. This means your choice of color is fundamentally a choice of material, which directly impacts the coating's hardness, wear resistance, and overall performance.

How PVD Achieves Its Color Palette

Physical Vapor Deposition (PVD) is a sophisticated process that bonds a thin film of material to a substrate at an atomic level. The resulting color is a product of this specific material and its interaction with light.

It's Not Paint, It's a Material Deposit

The most critical concept to grasp is that PVD is not a liquid coating that dries. Instead, a solid source material (called a "target") is vaporized in a vacuum and deposits onto the part.

The color you see is the natural color of the resulting ceramic compound. For example, to get a gold color, a material that is intrinsically gold-colored—like Titanium Nitride—is deposited.

The Role of Target Materials

Different materials produce different colors and performance characteristics. The process can be precisely controlled by blending different gases and target materials to create a range of finishes.

- Gold/Brass Tones: Typically achieved using Titanium Nitride (TiN) or Zirconium Nitride (ZrN). TiN has a classic gold hue, while ZrN offers a lighter, brassier shade.

- Silver/Chrome Tones: Chromium Nitride (CrN) is used to create a bright, metallic silver finish that is highly resistant to corrosion.

- Black/Gray Tones: A variety of materials can produce these colors. Titanium Carbonitride (TiCN) provides a resilient gray finish, while Aluminum Titanium Nitride (AlTiN) or Titanium Aluminum Nitride (TiAlN) creates a very hard, smooth black or dark gray/violet finish.

- Rose Gold/Copper Tones: These are often created by introducing specific ratios of carbon and nitrogen with a titanium or zirconium target, forming Titanium Carbonitride (TiCN) or Zirconium Carbonitride (ZrCN).

- Bronze/Blue/Violet Tones: These colors are often achieved with more exotic materials or by precisely manipulating the thickness of the coating to create an "interference" effect, similar to how an oil slick creates a rainbow of colors.

The Impact of Surface Finish

The final appearance is also dictated by the substrate's original surface. The PVD process is incredibly thin and conforms perfectly to the surface it covers.

A part that is polished to a mirror shine before coating will have a mirror-like PVD finish. A part that is bead-blasted or brushed will have a matte or satin PVD finish. The color remains the same, but its reflectivity and texture change completely.

Understanding the Trade-offs

Choosing a PVD coating involves balancing aesthetics with functional requirements. A beautiful finish is useless if it doesn't withstand its operational environment.

Color vs. Hardness

The materials that create different colors have different levels of inherent hardness and durability.

For instance, AlTiN (often black) is significantly harder and has a higher operating temperature than TiN (gold). This makes it a superior choice for high-wear industrial applications like cutting tools, even if the primary goal is simply a black finish.

Shine vs. Perceived Wear

While a matte or brushed finish has the same durability as a polished one of the same material and thickness, it is far better at hiding minor scratches and fingerprints.

A highly polished surface will show every small abrasion, making it appear to "wear" faster, even if the coating itself has not worn through. Matte finishes diffuse light, making small imperfections much less noticeable.

Thickness vs. Cost and Tolerance

A thicker coating is generally more durable, but it comes at a cost. The PVD process takes longer, increasing expense.

Furthermore, on precision-engineered parts, a thick coating can alter critical dimensions and tolerances. The coating thickness must be accounted for during the initial design phase.

Making the Right Choice for Your Goal

Selecting the correct PVD coating requires defining your primary objective first.

- If your primary focus is maximum durability and wear resistance: Choose a coating based on its material properties first, such as AlTiN (black/dark gray) or TiCN (gray), as these are among the hardest options.

- If your primary focus is a specific decorative color: Select the material that produces your desired hue (like TiN for gold), but ensure you specify a coating thickness adequate for the product's expected wear and tear.

- If your primary focus is hiding daily wear on consumer products: Opt for a matte or brushed surface preparation before the PVD coating is applied, regardless of the final color.

Ultimately, choosing a PVD color is an exercise in material science, where aesthetics and performance are intrinsically linked.

Summary Table:

| PVD Color | Common Material(s) | Key Characteristics |

|---|---|---|

| Gold / Brass | Titanium Nitride (TiN), Zirconium Nitride (ZrN) | Classic gold hue, good all-around wear resistance |

| Silver / Chrome | Chromium Nitride (CrN) | Bright, metallic finish, excellent corrosion resistance |

| Black / Gray | Titanium Carbonitride (TiCN), AlTiN/TiAlN | Very hard, high temperature resistance, durable |

| Rose Gold / Copper | TiCN, ZrCN | Warm, decorative tones, good toughness |

| Bronze / Blue / Violet | Specialized material blends | Unique aesthetic, often via interference effects |

Ready to unlock the perfect balance of color and durability for your products? The right PVD coating enhances both aesthetics and performance. At KINTEK, we specialize in advanced PVD solutions for laboratory equipment and precision components. Our expertise ensures you get a finish that is not only visually stunning but also exceptionally durable and tailored to your specific application. Contact our experts today to discuss how we can elevate your product with the ideal PVD coating.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

People Also Ask

- How does hot pressing work? Achieve Maximum Density for Advanced Materials

- What is vacuum lamination? Achieve a Flawless, Durable Finish on Complex Shapes

- What is hot press forging? Creating Complex, High-Strength Metal Components

- What is hot press lamination? The Ultimate Guide to Strong, Durable Material Bonding

- What is the purpose of laminating? Protect and Enhance Your Documents for Long-Term Use