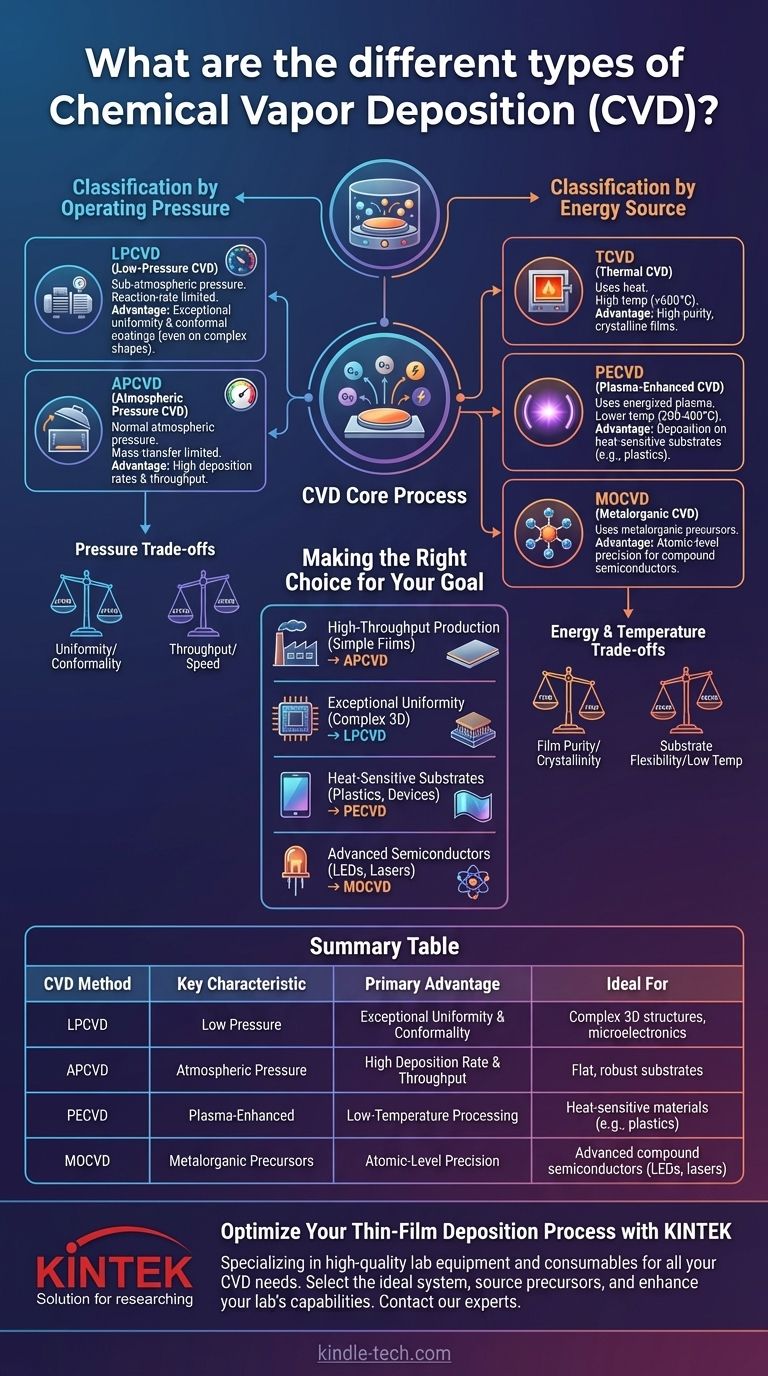

At its core, Chemical Vapor Deposition (CVD) is not a single technique but a family of processes. The primary types are distinguished by their operating pressure and the energy source used to initiate the chemical reaction. Key methods include Atmospheric Pressure CVD (APCVD) and Low-Pressure CVD (LPCVD) for pressure-based categories, and Thermal CVD (TCVD), Plasma-Enhanced CVD (PECVD), and Metalorganic CVD (MOCVD) for energy-based categories.

The specific CVD method you choose is dictated by your goal. The decision is a strategic trade-off between deposition temperature, operating pressure, and the precursor material required to achieve the desired film properties on a specific substrate.

The Fundamental Classifications of CVD

Chemical Vapor Deposition is a process where a solid material, typically a thin film, is deposited onto a heated substrate via a chemical reaction from a vapor or gas phase. The various methods are simply different ways to control this reaction. We can classify them along two main axes: operating pressure and energy source.

Classification by Operating Pressure

The pressure inside the reaction chamber dramatically affects how precursor gases move and react, influencing the final film's quality.

Low-Pressure CVD (LPCVD)

In LPCVD, the process is run at sub-atmospheric pressures. This reduces the concentration of gas molecules in the chamber.

As a result, the deposition is reaction-rate limited. The chemical reaction on the substrate surface is the slowest step, not the transport of gas to the surface. This leads to exceptionally uniform and conformal coatings, even over complex, non-flat topologies.

Atmospheric Pressure CVD (APCVD)

APCVD operates at normal atmospheric pressure. The chamber is dense with gas molecules, meaning the process is mass-transfer limited.

The rate-limiting step is how quickly the precursor gas can diffuse through the boundary layer to reach the substrate. While this allows for very high deposition rates and throughput, it can result in less uniform films compared to LPCVD.

Classification by Energy Source

The energy source is what breaks down the precursor gases and drives the chemical reaction. The choice of energy source is often determined by the temperature your substrate can tolerate.

Thermal CVD (TCVD)

This is the foundational CVD method. It uses heat as the sole energy source to decompose the precursor gases.

Substrates are heated to high temperatures (often >600°C), triggering the reaction. A common variant is Hot-Filament CVD (HFCVD), where a heated filament is used to catalytically decompose the gases, allowing for slightly lower substrate temperatures.

Plasma-Enhanced CVD (PECVD)

PECVD uses an energized plasma to decompose the precursor gases instead of relying solely on high heat.

This is a critical advantage because it allows for deposition at much lower temperatures (typically 200-400°C). This makes PECVD ideal for depositing films on substrates that cannot withstand the high heat of traditional TCVD, such as plastics or completed electronic devices.

Metalorganic CVD (MOCVD)

MOCVD is a specialized form of thermal CVD that uses metalorganic compounds as precursors. These are molecules containing a metal-carbon bond.

This technique offers extremely precise control over film thickness and composition down to a single atomic layer. It is the dominant method for manufacturing high-performance compound semiconductors used in LEDs, lasers, and high-frequency electronics.

Specialized Precursor Delivery Methods

For precursors that are liquid or solid at room temperature, specialized delivery systems are needed.

- Aerosol-Assisted CVD (AACVD): The precursor is dissolved in a solvent and an aerosol (a fine mist) is generated and transported into the reaction chamber.

- Direct Liquid Injection (DLI-CVD): A precise amount of liquid precursor is injected directly into a heated vaporization zone before entering the main chamber.

Understanding the Trade-offs

Choosing a CVD method involves balancing competing factors. There is no single "best" technique; there is only the best fit for your application.

Temperature vs. Film Purity

High-temperature processes like TCVD generally produce higher-purity, more crystalline films. However, this high heat limits your choice of substrates.

Low-temperature processes like PECVD are compatible with a wide range of materials but may result in more amorphous films or incorporate contaminants (like hydrogen) from the plasma.

Pressure vs. Conformality

LPCVD excels at creating highly conformal coatings that uniformly cover complex 3D structures. This is essential for modern microelectronics.

APCVD is faster and simpler but struggles with conformality. The deposition is often thicker on surfaces that the gas flow reaches first, making it better suited for flat substrates where high throughput is the priority.

Simplicity vs. Precision

Methods like APCVD and TCVD are conceptually simpler and often cheaper to implement.

Specialized techniques like MOCVD are far more complex and expensive but provide unparalleled control over the atomic structure of the film, which is non-negotiable for advanced optoelectronics.

Making the Right Choice for Your Goal

Your application's requirements will point you directly to the appropriate CVD method.

- If your primary focus is high-throughput production of simple films on robust substrates: APCVD is the most cost-effective choice due to its high deposition rate.

- If your primary focus is exceptional film uniformity and coating complex 3D structures: LPCVD provides the superior conformality required for advanced microfabrication.

- If your primary focus is depositing a film on a heat-sensitive substrate like plastic or a finished device: PECVD is the essential choice, as its low-temperature process prevents damage.

- If your primary focus is fabricating advanced compound semiconductor devices like LEDs or lasers: MOCVD is the industry standard, offering the atomic-level precision necessary.

Ultimately, selecting the right CVD process is a matter of aligning the technique's capabilities with the specific material properties and manufacturing constraints of your project.

Summary Table:

| CVD Method | Key Characteristic | Primary Advantage | Ideal For |

|---|---|---|---|

| LPCVD | Low Pressure | Exceptional Uniformity & Conformality | Coating complex 3D structures, microelectronics |

| APCVD | Atmospheric Pressure | High Deposition Rate & Throughput | High-throughput production on flat, robust substrates |

| PECVD | Plasma-Enhanced | Low-Temperature Processing | Depositing films on heat-sensitive materials (e.g., plastics) |

| MOCVD | Metalorganic Precursors | Atomic-Level Precision | Advanced compound semiconductors (LEDs, lasers) |

Optimize Your Thin-Film Deposition Process with KINTEK

Navigating the complexities of Chemical Vapor Deposition is crucial for achieving the precise film properties your research or production demands. The right equipment is the foundation of success.

KINTEK specializes in providing high-quality lab equipment and consumables for all your CVD needs. Whether you are developing next-generation semiconductors, creating protective coatings, or advancing materials science, we have the expertise and solutions to support your work.

Let us help you:

- Select the ideal CVD system (LPCVD, PECVD, MOCVD, etc.) for your specific application and substrate requirements.

- Source the necessary precursors and consumables to ensure consistent, high-purity results.

- Enhance your lab's capabilities with reliable equipment that delivers precision and repeatability.

Ready to achieve superior thin films? Contact our experts today for a personalized consultation. We'll work with you to understand your goals and recommend the perfect CVD solution to drive your innovation forward.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is the function of a high-temperature CVD tube furnace in 3D graphene foam prep? Master 3D Nanomaterial Growth

- What is the sputtering process in chemistry? A Physical Vapor Deposition Technique for Thin Films

- What is the chemical vapor deposition method? A Guide to High-Purity Thin Film Manufacturing

- What is hot filament chemical vapor deposition? A Guide to High-Purity Diamond Film Growth

- What is the purpose of chemical Vapour deposition? To Engineer Superior Surface Properties

- Why is precise substrate heating essential for TiO2/Al-Zr bilayer thin films? Master AA-MOCVD Thermal Control

- What is the process of CVD? A Step-by-Step Guide to Chemical Vapor Deposition

- How many types of vapor phase deposition techniques are present? PVD vs. CVD Explained