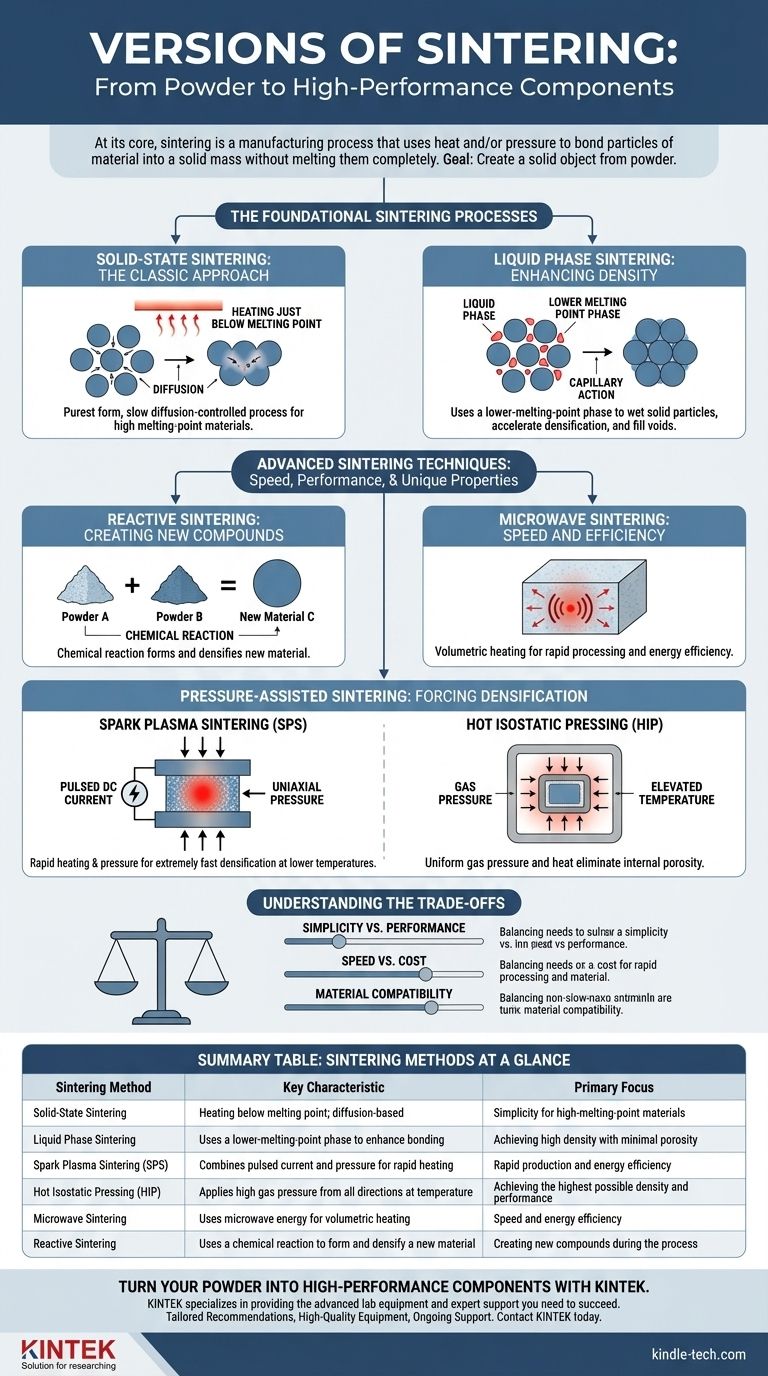

At its core, sintering is a manufacturing process that uses heat and/or pressure to bond particles of material into a solid mass without melting them completely. The primary versions are Solid-State Sintering and Liquid Phase Sintering, but several advanced, pressure-assisted, and energy-driven methods have been developed for specialized applications, including Microwave Sintering, Spark Plasma Sintering, and Hot Isostatic Pressing.

The fundamental goal of sintering is always the same: create a solid object from powder. The various methods simply represent different tools for achieving that goal, each trading off speed, cost, final density, and material compatibility to solve specific engineering challenges.

The Foundational Sintering Processes

The most common and fundamental methods are distinguished by whether the material remains entirely solid or if a small amount of liquid is introduced to aid the process.

Solid-State Sintering: The Classic Approach

Solid-state sintering is the purest form of the process. Powdered material is compacted and then heated to a temperature just below its melting point.

At this high temperature, the atoms at the contact points between particles become agitated and diffuse across the boundaries, effectively fusing the particles together. This is a slow, diffusion-controlled process.

It is the standard method for materials with exceptionally high melting points, such as tungsten or molybdenum, where reaching a molten state is impractical or undesirable.

Liquid Phase Sintering: Enhancing Density

In liquid phase sintering, a small amount of a liquid is present during the heating process. This is achieved by mixing powders where one has a lower melting point than the other.

This liquid phase wets the solid particles and pulls them together through capillary action, accelerating particle rearrangement and densification. This results in a final part with much lower porosity compared to solid-state sintering.

The liquid helps fill the voids between solid particles, acting like a binding agent that solidifies upon cooling, creating a dense, strong final product.

Advanced Sintering Techniques

Modern manufacturing demands greater speed, higher performance, and unique material properties, leading to the development of more advanced sintering methods.

Reactive Sintering: Creating New Compounds

This method intentionally uses a chemical reaction to its advantage. Two or more different powders are mixed and heated, causing them to react and form an entirely new chemical compound.

The heat generated by the reaction itself often contributes to the sintering process, simultaneously forming and densifying the new material.

Microwave Sintering: Speed and Efficiency

Instead of conventional radiant heating, this technique uses microwaves to heat the material. The microwaves couple directly with the material, causing it to heat rapidly and uniformly from the inside out.

This "volumetric heating" can drastically reduce processing time and energy consumption compared to traditional furnace-based methods.

Pressure-Assisted Sintering: Forcing Densification

For applications requiring near-perfect density and superior mechanical properties, pressure is added to the equation.

Spark Plasma Sintering (SPS) uses a combination of high-amperage pulsed DC current and uniaxial pressure. The current creates rapid heating at the particle contact points, while the pressure forces them together, enabling extremely fast densification at lower overall temperatures.

Hot Isostatic Pressing (HIP) involves placing the powdered material in a sealed container and subjecting it to high inert gas pressure from all directions (isostatically) at an elevated temperature. This combination of uniform pressure and heat is exceptionally effective at eliminating internal porosity.

Understanding the Trade-offs

Choosing a sintering method requires balancing performance requirements with practical constraints. No single process is best for every application.

Simplicity vs. Performance

Solid-state sintering is relatively simple and inexpensive but may result in parts with residual porosity. Advanced methods like HIP produce superior, fully dense parts but require highly specialized and costly equipment.

Speed vs. Cost

Processes like Microwave Sintering and SPS are valued for their incredible speed, which can lower operational costs and increase throughput. However, the initial capital investment for this equipment is significantly higher than for a conventional sintering furnace.

Material Compatibility

The chosen method must be compatible with the material. For example, SPS works best with electrically conductive materials. Microwave Sintering requires materials that can absorb microwave energy efficiently.

Making the Right Choice for Your Goal

Your final decision should be driven by the specific properties you need in your component and the materials you are working with.

- If your primary focus is processing pure, high-melting-point materials simply: Solid-state sintering is the established and most straightforward choice.

- If your primary focus is achieving high density with minimal porosity: Liquid Phase Sintering is a practical upgrade, while Hot Isostatic Pressing (HIP) offers the highest possible performance.

- If your primary focus is rapid production and energy efficiency: Microwave Sintering and Spark Plasma Sintering (SPS) are the leading high-speed options.

- If your primary focus is creating a new material during the process: Reactive Sintering is the specific method designed for this purpose.

Understanding these distinct sintering pathways empowers you to engineer materials with precision, turning simple powders into high-performance components.

Summary Table:

| Sintering Method | Key Characteristic | Primary Focus |

|---|---|---|

| Solid-State Sintering | Heating below melting point; diffusion-based | Simplicity for high-melting-point materials |

| Liquid Phase Sintering | Uses a lower-melting-point phase to enhance bonding | Achieving high density with minimal porosity |

| Spark Plasma Sintering (SPS) | Combines pulsed current and pressure for rapid heating | Rapid production and energy efficiency |

| Hot Isostatic Pressing (HIP) | Applies high gas pressure from all directions at temperature | Achieving the highest possible density and performance |

| Microwave Sintering | Uses microwave energy for volumetric heating | Speed and energy efficiency |

| Reactive Sintering | Uses a chemical reaction to form and densify a new material | Creating new compounds during the process |

Turn Your Powder into High-Performance Components with KINTEK

Choosing the right sintering process is critical to achieving the desired density, strength, and material properties for your lab's projects. Each method—from the simplicity of Solid-State Sintering to the high-performance of Hot Isostatic Pressing—offers unique advantages for specific applications.

KINTEK specializes in providing the advanced lab equipment and expert support you need to succeed. Whether you are processing high-melting-point metals, creating new compounds, or requiring rapid, energy-efficient production, we have the sintering solutions for you.

Let our experts help you select the ideal equipment to meet your goals. We provide:

- Tailored Recommendations: Get advice on the best sintering method for your specific material and performance requirements.

- High-Quality Equipment: From standard furnaces to advanced Spark Plasma Sintering and Hot Isostatic Pressing systems.

- Ongoing Support: Ensure your lab operates at peak efficiency with our comprehensive service and support.

Contact KINTEK today to discuss your sintering needs and discover how our solutions can enhance your research and production capabilities.

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What are the advantages of vacuum sintering? Achieve Superior Purity, Strength, and Performance

- What is the impact factor of powder metallurgy progress? A 2022 Analysis & Context

- What are the primary advantages of using a vacuum hot pressing sintering furnace? Maximize Density in B4C-CeB6 Ceramics

- How does a vacuum environment system contribute to the hot pressing sintering of B4C-CeB6? Unlock Peak Ceramic Density

- What critical processing conditions does a vacuum hot pressing sintering furnace provide for high-density VC/Cu?