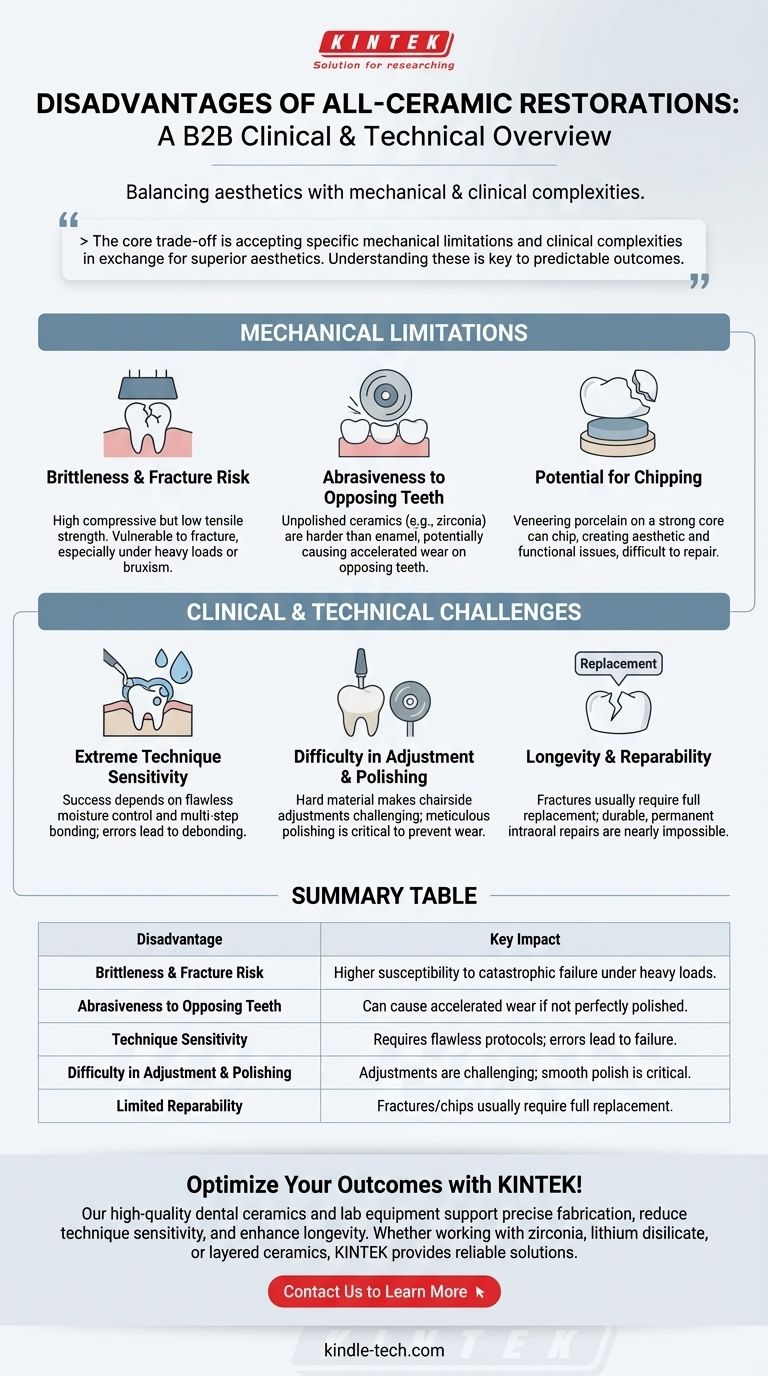

While prized for their appearance, the primary disadvantages of all-ceramic restorations are their inherent brittleness, their potential to wear down opposing natural teeth, and the demanding, technique-sensitive procedures required for successful, long-term bonding. These factors mean they are not universally suitable for every clinical situation or patient.

The core trade-off with all-ceramic restorations is accepting specific mechanical limitations and clinical complexities in exchange for superior aesthetics. Understanding these limitations is not a critique of the material but the key to predictable, successful outcomes.

The Mechanical Limitations of Ceramic

The fundamental properties of ceramic materials give rise to their most significant disadvantages. Unlike metals, which can bend or deform under pressure, ceramics are rigid and will fracture when their structural limit is reached.

Brittleness and Fracture Risk

Ceramics possess high compressive strength but low tensile strength. This means they are very resistant to being pushed on but are vulnerable to forces that pull or bend them.

This brittleness makes them more susceptible to catastrophic fracture, especially in thin sections or under heavy functional loads, such as in patients who grind their teeth (bruxism).

Abrasiveness to Opposing Teeth

Certain types of ceramic, particularly unpolished zirconia, are significantly harder than natural tooth enamel.

If the ceramic surface is not perfectly polished after an adjustment, it can act like fine sandpaper, causing accelerated and destructive wear on the opposing natural teeth. This is a critical long-term consideration.

Potential for Chipping

For restorations that use a strong ceramic core (like zirconia) with a weaker, more aesthetic porcelain layered on top, chipping is a known risk.

While the core itself may not break, the veneering porcelain can chip away, creating an aesthetic and functional problem that is very difficult to repair predictably.

Clinical and Technical Challenges

The success of an all-ceramic restoration is highly dependent on the skill of the clinician and laboratory technician. The process is far less forgiving than for traditional metal-based restorations.

Extreme Technique Sensitivity

Bonding a ceramic restoration to a tooth is a complex, multi-step process. Success depends on perfect isolation from moisture (saliva, blood) and meticulous execution of each step, from etching the tooth to curing the adhesive resin.

Any procedural error can lead to a compromised bond, which is a primary cause of debonding and premature failure.

Difficulty in Adjustment and Polishing

Making chairside adjustments to a ceramic crown's bite or shape is challenging. The material's hardness makes it difficult to cut smoothly with dental burs.

More importantly, achieving a high-gloss, smooth polish after an adjustment is critical to prevent wear of opposing teeth. This requires a specific set of polishing instruments and takes considerable time and care.

Longevity and Reparability

While strong, ceramics are not indestructible. If a fracture occurs, it is nearly impossible to perform a durable, permanent repair inside the mouth.

Unlike some other materials, a significant chip or fracture in a ceramic restoration almost always necessitates a complete replacement of the crown or veneer.

Making the Right Choice for Your Goal

Selecting the right material requires balancing the patient's aesthetic demands with the functional forces and clinical realities of their specific case.

- If your primary focus is maximum aesthetics in a low-stress area (e.g., front teeth): Materials like feldspathic porcelain or lithium disilicate are often preferred, accepting a lower fracture resistance for the best possible appearance.

- If your primary focus is maximum strength and durability (e.g., back molars or patients who grind): Monolithic zirconia is the superior choice, but it requires meticulous polishing and may involve an aesthetic compromise.

- If your primary focus is a balance of strength and appearance: Layered zirconia or lithium disilicate restorations offer an excellent compromise, providing good durability for most situations while maintaining high-end aesthetics.

Ultimately, recognizing the specific disadvantages of all-ceramic materials is the first step toward leveraging their incredible strengths for a successful and lasting result.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Brittleness & Fracture Risk | Higher susceptibility to catastrophic failure under heavy loads, especially in thin sections or bruxism patients. |

| Abrasiveness to Opposing Teeth | Can cause accelerated wear on natural enamel if not perfectly polished, particularly with zirconia. |

| Technique Sensitivity | Requires flawless moisture control and bonding protocols; errors can lead to debonding or premature failure. |

| Difficulty in Adjustment & Polishing | Hard material makes chairside adjustments challenging; achieving a smooth polish is critical and time-consuming. |

| Limited Reparability | Fractures or chips usually require full restoration replacement, as durable repairs are difficult. |

Optimize your ceramic restoration outcomes with KINTEK! Our high-quality dental ceramics and lab equipment are designed to support precise fabrication, reduce technique sensitivity, and enhance the longevity of your restorations. Whether you're working with zirconia, lithium disilicate, or layered ceramics, KINTEK provides reliable materials and tools tailored to dental laboratory needs. Contact us today to learn how our solutions can help you achieve durable, aesthetically superior results for your patients.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Can ceramic crowns be repaired? A Dentist's Guide to Assessing the Damage

- What is the temperature of zirconia? Mastering the Sintering Cycle for Maximum Strength

- What temperature do you fire zirconia? Master the Sintering Cycle for Peak Strength & Aesthetics

- What is a burnout furnace used for in dentistry? Create Perfect Dental Crowns & Bridges

- What is in a dental laboratory? Discover the High-Tech Hub Creating Your Perfect Smile

- What are the different types of temperature calibration systems used in porcelain furnaces? Ensure Precision for Every Ceramic Type

- What does sintering zirconia mean? The Key to Transforming Zirconia into a High-Strength Ceramic

- What are the different types of dental furnaces? Choose the Right Furnace for Your Dental Lab