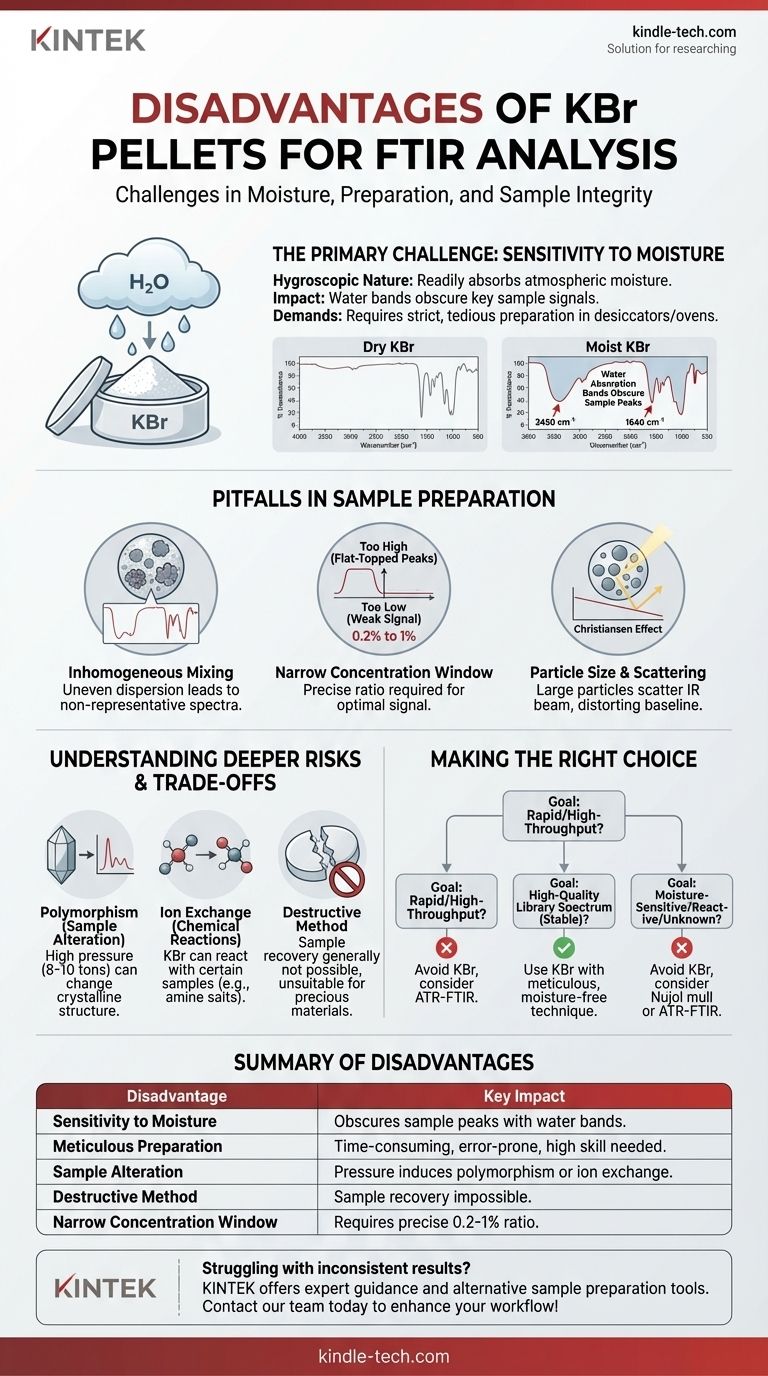

The primary disadvantages of the KBr pellet technique for FTIR analysis are its extreme sensitivity to moisture and the meticulous, error-prone sample preparation process. These factors can easily introduce artifacts and inconsistencies into the resulting spectrum, compromising the quality and reproducibility of your data.

The core issue with KBr pellets is not a fundamental flaw in the theory, but in the execution. The method's success is highly dependent on operator skill and a controlled environment, as procedural errors, especially moisture contamination and improper sample dispersion, can easily ruin an analysis.

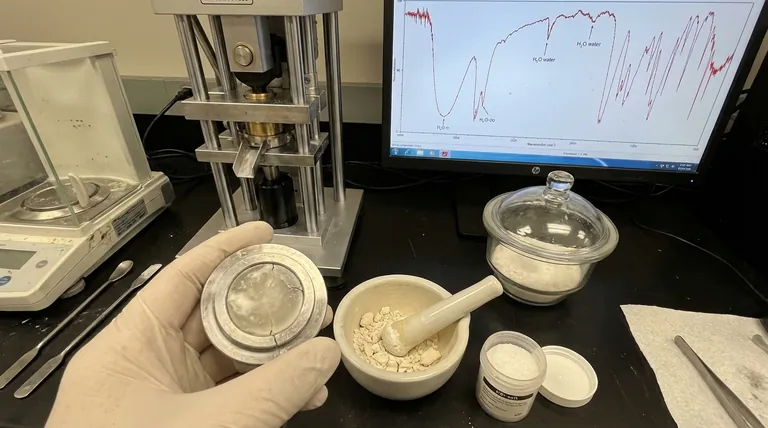

The Primary Challenge: Sensitivity to Moisture

The most significant and persistent problem when working with potassium bromide (KBr) is its interaction with water. This single factor is the source of the most common failures in the technique.

KBr's Hygroscopic Nature

Potassium bromide is hygroscopic, meaning it readily absorbs moisture from the atmosphere. Any exposure of the KBr powder to ambient air will result in water contamination.

The Impact of Water on Spectra

Water has very strong and broad absorption bands in the infrared spectrum, particularly around 3450 cm⁻¹ (O-H stretching) and 1640 cm⁻¹ (H-O-H bending). If water is present in your pellet, these large peaks can obscure important signals from your actual sample, making interpretation difficult or impossible.

Rigorous Procedural Demands

To combat moisture, a strict and often tedious preparation protocol is required. This involves heating dies and anvils, storing KBr powder in a desiccator or oven, and working quickly to minimize air exposure. This adds significant time and complexity to the analysis.

Pitfalls in Sample Preparation

Even if you manage to control for moisture, the physical preparation of the pellet presents several opportunities for error that can degrade spectral quality.

Risk of Inhomogeneous Mixing

The sample must be perfectly and evenly dispersed throughout the KBr matrix. If the blending is incomplete, different parts of the pellet will have different concentrations, leading to a non-representative and non-reproducible spectrum.

The Narrow Concentration Window

The ideal sample concentration in KBr is very low, typically 0.2% to 1%. If the concentration is too high, the sample will absorb nearly all the infrared light, resulting in "flat-topped," useless peaks. Too low, and the signal will be too weak to distinguish from baseline noise.

Particle Size and Scattering Effects

For a clear pellet, the sample's particle size must be ground to be smaller than the wavelength of the infrared light being used. If the particles are too large, they will scatter the IR beam instead of transmitting it, causing a sloping, distorted baseline known as the Christiansen effect.

Understanding the Deeper Risks and Trade-offs

Beyond the common procedural errors, there are inherent risks in the KBr method that can fundamentally alter your sample and your results.

Potential for Sample Alteration

The immense pressure used to form the pellet (often 8-10 tons) can sometimes induce polymorphism, a change in the crystalline structure of your sample. This change will alter its IR spectrum, meaning you are no longer analyzing the original material.

Unwanted Chemical Reactions

Because KBr is an alkali halide salt, it can undergo ion exchange with certain samples, such as amine hydrochloride salts. This chemical reaction creates a new compound within the pellet, and the resulting spectrum will not be of your starting material.

The Method is Destructive

The process of grinding a sample and pressing it into a KBr pellet is destructive and irreversible. Sample recovery is generally not feasible, which can be a significant drawback when working with precious or limited quantities of material.

Making the Right Choice for Your Goal

Understanding these disadvantages is key to deciding if the KBr pellet technique is appropriate for your specific analytical need.

- If your primary focus is rapid or high-throughput analysis: Avoid the KBr pellet method. Its time-consuming and skill-dependent nature makes it unsuitable; consider ATR-FTIR instead.

- If your primary focus is obtaining a high-quality library spectrum of a stable compound: The KBr method can produce excellent results, but only if you commit to a meticulous, moisture-free preparation technique.

- If your primary focus is analyzing a moisture-sensitive, reactive, or unknown sample: The KBr method is a high-risk choice. Alternative methods like a Nujol mull or ATR-FTIR are far safer and more reliable.

By recognizing these potential pitfalls, you can make a more informed decision and produce more reliable and accurate spectroscopic data.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Sensitivity to Moisture | Obscures sample peaks with water absorption bands. |

| Meticulous Preparation | Time-consuming, error-prone, requires high operator skill. |

| Sample Alteration | High pressure can induce polymorphism or ion exchange. |

| Destructive Method | Sample recovery is generally not possible. |

| Narrow Concentration Window | Requires precise sample-to-KBr ratio (0.2-1%). |

Struggling with inconsistent FTIR results from KBr pellets? KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you select the right FTIR accessories or alternative sample preparation tools to achieve reliable, high-quality spectra. Contact our team today to discuss your specific application and enhance your analytical workflow!

Visual Guide

Related Products

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- kbr pellet press 2t

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

People Also Ask

- What is the pressed pellet technique? A Guide to Creating Uniform Solid Samples from Powder

- What is a punch tablet press? Precision Tableting for R&D and Small Batches

- What is tablet pressing in pharmaceutical industry? The Core Process for Producing Solid Oral Dosage Forms

- What are the two classifications of press machines? Single Punch vs. Rotary Presses Explained

- What are the advantages of press working operation? Unlock High-Speed, Low-Cost Mass Production