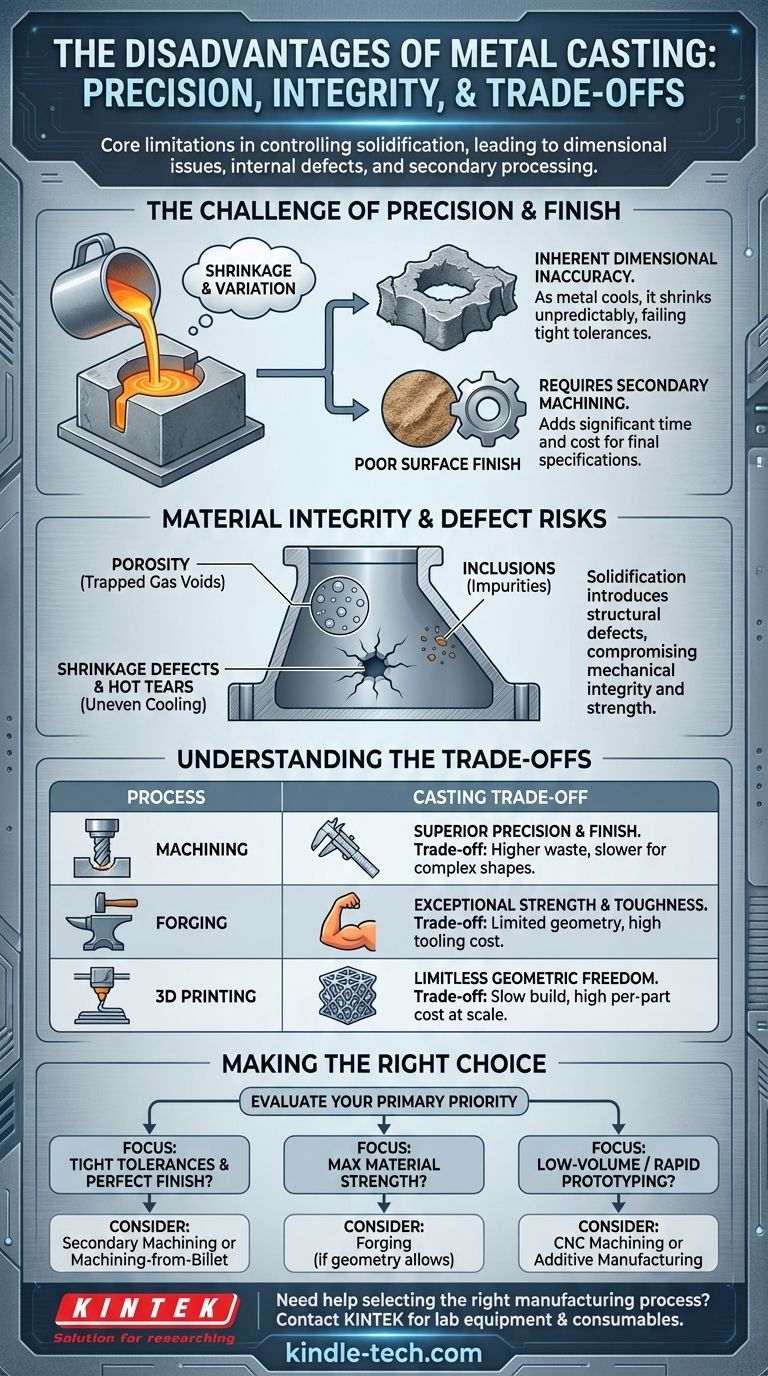

While a foundational and versatile manufacturing process, metal casting is defined by a critical set of limitations. The primary disadvantages stem from challenges in controlling the solidification process, leading to issues with dimensional accuracy, the potential for internal defects, and the frequent need for costly secondary processing to meet final specifications.

The core trade-off with metal casting is sacrificing dimensional accuracy, surface finish, and potentially material strength for the ability to produce complex geometric shapes, often in high volumes, at a relatively low per-unit cost.

The Challenge of Precision and Finish

The most immediate and common drawbacks of casting relate to the final dimensions and surface quality of the part. These issues often necessitate additional manufacturing steps, adding time and cost.

Inherent Dimensional Inaccuracy

As molten metal cools and solidifies, it shrinks. Predicting and controlling this shrinkage with perfect uniformity across a complex geometry is extremely difficult.

This leads to finished parts that may not meet tight dimensional tolerances. Factors like mold deformation and slight variations in cooling rates contribute to this imprecision.

Poor Surface Finish

The surface of a cast part is a direct replica of the mold's interior surface. For common processes like sand casting, this results in a characteristically rough texture.

Even with smoother mold materials, the as-cast finish is rarely acceptable for mating surfaces, sealing areas, or components where aesthetics are critical.

The Necessity of Secondary Machining

Because of poor tolerances and surface finish, almost all castings require secondary machining.

This involves processes like milling, turning, drilling, or grinding to achieve the final required dimensions and smoothness. This post-processing step adds significant cost and negates some of the initial speed advantages of casting.

Material Integrity and Defect Risks

The transition from a liquid to a solid state is a volatile process that can introduce a range of structural defects, compromising the mechanical integrity of the final component.

Porosity

Gases can dissolve in molten metal and then get trapped as bubbles when the metal solidifies. This creates small internal voids known as porosity.

These voids act as stress concentrators, reducing the part's overall strength and making it susceptible to failure under load, especially fatigue.

Shrinkage and Hot Tears

If thicker sections of a casting cool more slowly than adjacent thinner sections, it can create voids or depressions called shrinkage defects.

Furthermore, if the part is constrained from shrinking freely by the mold, it can lead to stress build-up that causes cracks to form while the metal is still hot, a defect known as hot tearing or hot cracking.

Inclusions

Non-metallic impurities, such as particles from the mold material (sand grains), slag, or oxides, can become trapped within the solidifying metal.

These inclusions disrupt the metallic grain structure and create weak points within the part, similar to the effect of porosity.

Understanding the Trade-offs: Casting vs. Other Processes

The disadvantages of casting are best understood in comparison to alternative manufacturing methods. Your choice depends entirely on the part's specific requirements.

Casting vs. Machining

Machining from a solid block of metal (billet) offers superior dimensional accuracy and surface finish. It also produces a part with a more uniform and predictable internal structure.

The trade-off is waste and time. Machining is a subtractive process that creates significant scrap material (chips) and can be much slower and more expensive for producing complex shapes from scratch.

Casting vs. Forging

Forging involves shaping metal using compressive forces, which refines the metal's grain structure and yields parts with exceptional strength, toughness, and fatigue resistance.

However, forging is limited to less complex geometries than casting and typically carries a higher tooling cost, making it better suited for high-performance applications where strength is paramount.

Casting vs. Additive Manufacturing (3D Printing)

Metal 3D printing provides almost limitless geometric freedom with no upfront tooling costs, making it ideal for prototypes, custom parts, and highly complex, low-volume components.

The primary disadvantage of 3D printing is its slow build speed and high per-part cost at scale, making casting far more economical for mass production.

Making the Right Choice for Your Goal

To decide if casting's drawbacks are acceptable for your project, evaluate your primary engineering priority.

- If your primary focus is tight tolerances and a perfect finish: Plan for significant secondary machining or consider starting with a machined-from-billet approach.

- If your primary focus is maximum material strength and fatigue resistance: Forging is the superior process for parts with geometries that allow for it.

- If your primary focus is low-volume production or rapid prototyping: Avoid casting's high tooling costs and explore CNC machining or additive manufacturing instead.

Understanding these inherent limitations is the key to leveraging casting effectively and avoiding costly manufacturing mismatches.

Summary Table:

| Disadvantage Category | Key Issues | Impact on Final Part |

|---|---|---|

| Precision & Finish | Dimensional inaccuracy, rough surface | Requires secondary machining, adds cost |

| Material Integrity | Porosity, shrinkage, hot tears, inclusions | Reduced strength, fatigue resistance, potential failure |

| Process Comparison | Less accurate than machining, weaker than forging, slower than 3D printing for prototypes | Not ideal for high-precision, high-strength, or low-volume needs |

Need help selecting the right manufacturing process for your lab or production needs? At KINTEK, we specialize in providing lab equipment and consumables to help you analyze materials, test prototypes, and ensure quality control—whether you're working with cast, forged, or 3D-printed parts. Contact our experts today to discuss how we can support your project with precision tools and reliable solutions tailored to laboratory requirements.

Visual Guide

Related Products

- Isostatic Molding Pressing Molds for Lab

- High-Purity Titanium Foil and Sheet for Industrial Applications

People Also Ask

- What are the grades of graphite? A Practical Guide to Choosing the Right Material for Your Application

- What is the purpose of sputter coating? Achieve Atomic-Scale Precision and Uniformity

- Why is DC sputtering used for metals? Unlock Faster, More Cost-Effective Metal Deposition

- What does sputter coating do? Achieve Superior, Atomic-Level Film Deposition

- What are the advantages of a wiped film evaporator? Purify Heat-Sensitive Materials Without Degradation

- How does Rotavapor work? Master Gentle, Low-Temperature Solvent Evaporation

- What are the effects of heat treatment and temperature on properties of metals? Master Hardness, Toughness, and More

- What are the disadvantages of metal iron? Key Limitations and Why We Use Alloys Instead