At its core, the primary disadvantages of Physical Vapour Deposition (PVD) are its high operational cost and the time-intensive nature of its vacuum-based process. These factors stem directly from the complex equipment required to create and maintain the high-vacuum environment essential for the deposition to occur.

While PVD is celebrated for producing high-purity, high-performance coatings, its main drawbacks—cost, process time, and geometric limitations—are inherent to its line-of-sight physical mechanism. Understanding these limitations is critical when comparing it to alternative methods like Chemical Vapour Deposition (CVD).

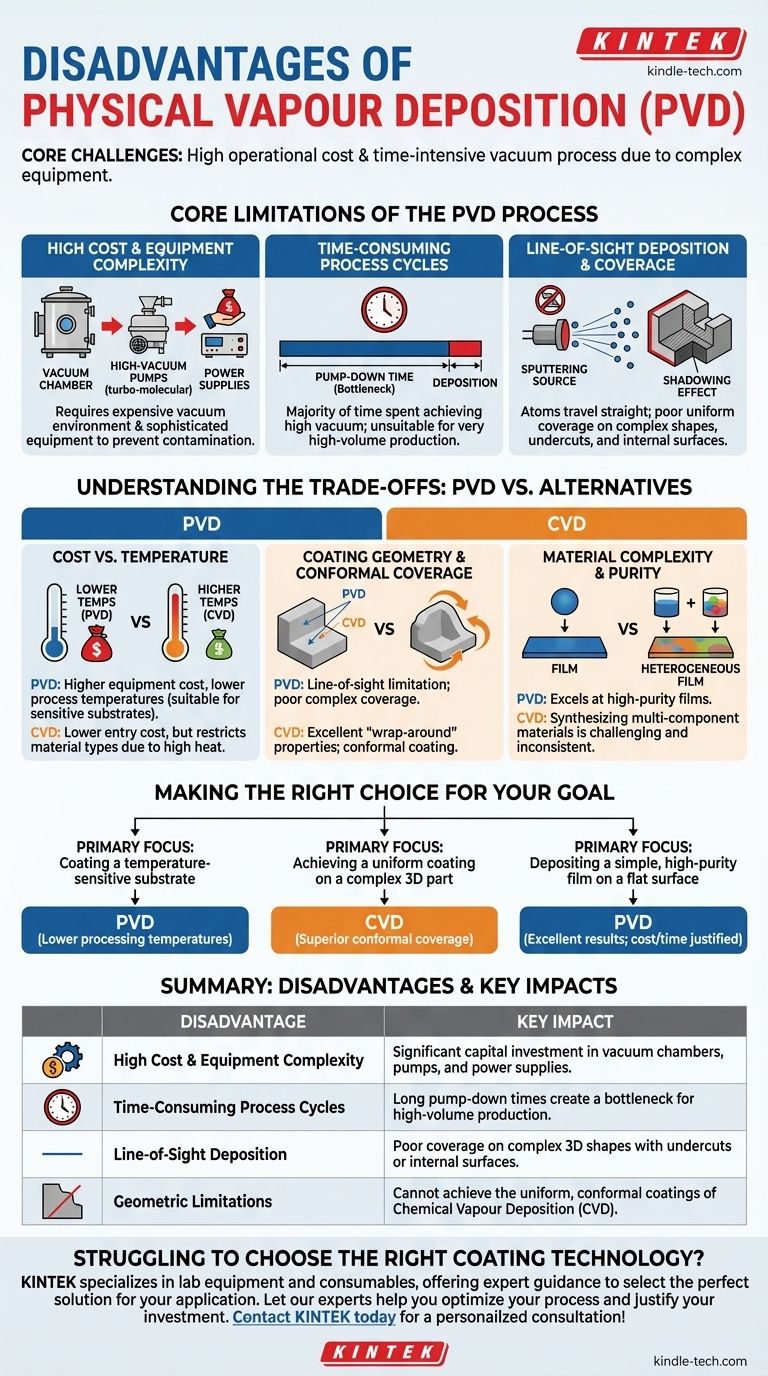

The Core Limitations of the PVD Process

The challenges associated with PVD are not incidental; they are fundamental to how the technology works. The process involves physically ejecting atoms from a source material (the "target") and having them travel through a vacuum to condense onto a substrate.

High Cost and Equipment Complexity

The single biggest barrier to PVD is the investment in equipment. The process requires a high-vacuum environment to prevent contamination and ensure atoms can travel freely from the target to the substrate.

This necessitates expensive vacuum chambers, powerful pumps (like turbo-molecular and cryogenic pumps), and sophisticated power supplies for the sputtering or evaporation source. The cost of high-purity target materials also contributes to the overall expense.

Time-Consuming Process Cycles

While the actual deposition of material can be fast, the overall process cycle is often long. The majority of the time is spent pumping the chamber down to the required vacuum level before deposition can even begin.

This "pump-down" time can be a significant bottleneck in a production environment, making PVD less suitable for very high-volume, low-margin applications compared to atmospheric pressure techniques.

Line-of-Sight Deposition and Coverage

PVD is fundamentally a "line-of-sight" process. Atoms travel in a relatively straight line from the source to the substrate.

This makes it extremely difficult to achieve a uniform coating on complex, three-dimensional shapes with undercuts, sharp corners, or internal surfaces. The parts of the substrate not directly facing the source will receive little to no coating, creating a "shadowing" effect.

Understanding the Trade-offs: PVD vs. Alternatives

The disadvantages of PVD only become clear when weighed against its benefits and the characteristics of other methods, such as Chemical Vapour Deposition (CVD).

The Cost vs. Temperature Dilemma

PVD generally operates at lower temperatures than thermally-activated CVD, which can require temperatures of 850-1100°C. This makes PVD suitable for coating temperature-sensitive substrates (like plastics or certain alloys) that would be damaged by high-heat CVD processes.

The trade-off is clear: PVD involves higher equipment cost but offers lower process temperatures, while traditional CVD may have lower entry costs but restricts the types of materials you can coat.

Coating Geometry and Conformal Coverage

This is a defining difference. As noted in the references, CVD offers good "wrap-around" properties. Because it relies on a chemical gas precursor that fills the entire chamber, it can deposit a highly uniform, or conformal, coating over complex shapes.

PVD, with its line-of-sight limitation, cannot compete in this area. If uniform coverage on a non-flat part is the primary goal, CVD is often the superior choice.

Material Complexity and Purity

PVD excels at depositing extremely high-purity films, as the process simply transfers material from a pure source in a clean vacuum.

Conversely, synthesizing multi-component materials with CVD can be challenging. It requires balancing the vapor pressures and reaction rates of multiple chemical precursors, which can lead to an inconsistent or heterogeneous final composition. PVD offers more straightforward control for many alloyed or multi-layer films.

Making the Right Choice for Your Goal

Selecting the correct deposition technology requires aligning its strengths and weaknesses with your primary objective.

- If your primary focus is coating a temperature-sensitive substrate: PVD is the clear choice due to its fundamentally lower processing temperatures.

- If your primary focus is achieving a uniform coating on a complex 3D part: CVD is almost always the better option because of its superior conformal coverage.

- If your primary focus is depositing a simple, high-purity film on a flat surface: PVD provides excellent results, though the cost and time per cycle must be justified by the application.

Ultimately, choosing between these technologies is a matter of balancing the geometric, thermal, and chemical requirements of your specific application against the inherent costs and limitations of each process.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| High Cost & Equipment Complexity | Significant capital investment in vacuum chambers, pumps, and power supplies. |

| Time-Consuming Process Cycles | Long pump-down times create a bottleneck for high-volume production. |

| Line-of-Sight Deposition | Poor coverage on complex 3D shapes with undercuts or internal surfaces. |

| Geometric Limitations | Cannot achieve the uniform, conformal coatings of Chemical Vapour Deposition (CVD). |

Struggling to choose the right coating technology for your lab's specific needs?

The limitations of PVD are real, but the right equipment partner can help you navigate the trade-offs between PVD, CVD, and other methods. KINTEK specializes in lab equipment and consumables, serving laboratory needs with expert guidance to select the perfect solution for your application—whether it's coating temperature-sensitive substrates or achieving uniform coverage on complex parts.

Let our experts help you optimize your process and justify your investment. Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- Why e-beam evaporation is developed for thin film processing? Unlock High-Purity Films for Advanced Applications

- What is the effect of substrate temperature on sputtering? Master Film Density, Crystallinity, and Stress

- What is step coverage in thermal evaporation? Avoid Device Failure with the Right Deposition Method

- Why do we need a vacuum for thin-film deposition? To Ensure Purity, Adhesion, and Process Control

- What is the thermal evaporation method? A Guide to Simple, Cost-Effective Thin-Film Deposition

- What is the difference between a condenser and an evaporator? The Key to Efficient Cooling Systems

- What is thermal evaporation technique thin film deposition? A Guide to Simple, Cost-Effective PVD

- What is the thickness of physical vapor deposition? Tailoring PVD Coating for Your Application