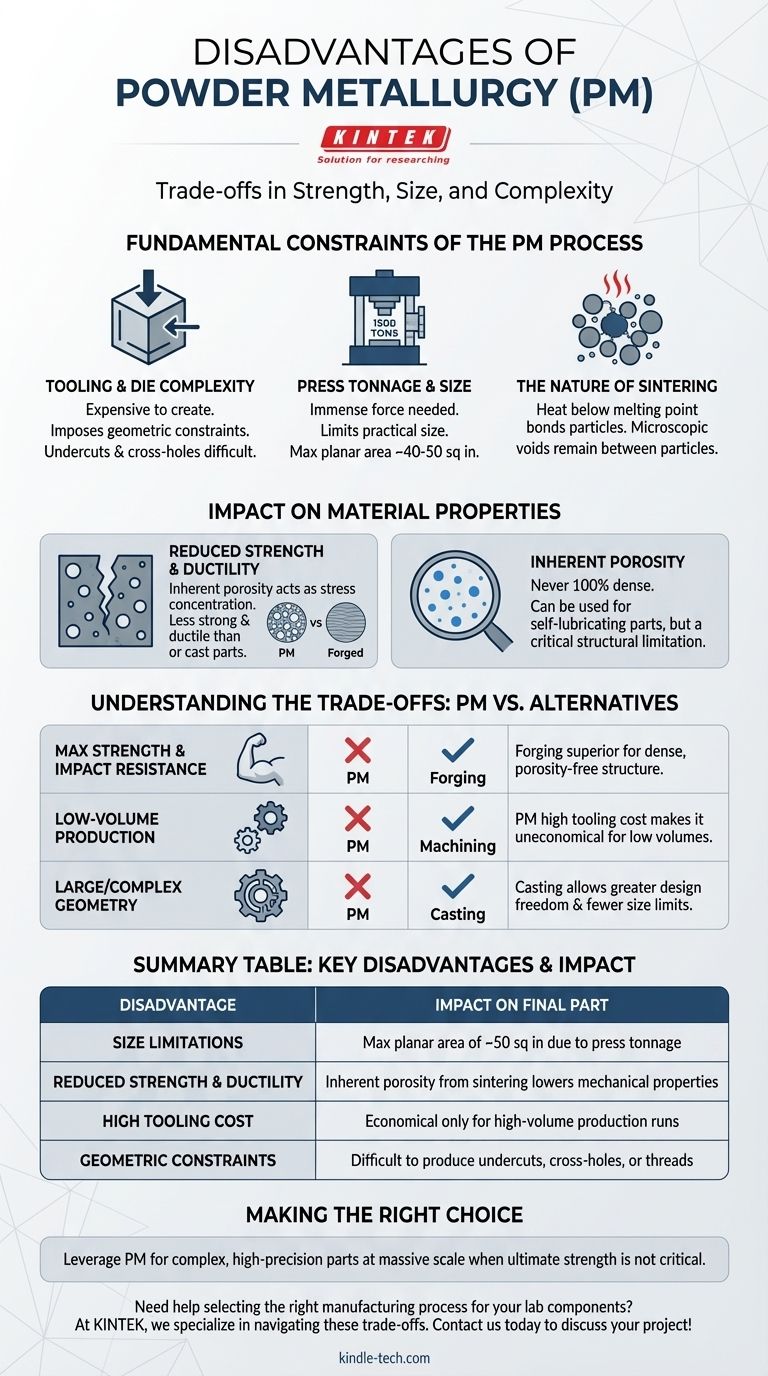

The primary disadvantages of powder metallurgy (PM) are its inherent limitations on part size, the challenge of producing certain complex geometries, and the resulting components having lower strength and ductility compared to fully dense methods like forging. These constraints stem directly from the core mechanics of pressing powder in a rigid die and sintering it below its melting point.

While powder metallurgy is a highly effective process for producing precise, net-shape parts in high volumes, its fundamental trade-off is sacrificing ultimate material strength and size for complexity and production efficiency.

The Fundamental Constraints of the PM Process

To understand the disadvantages of powder metallurgy, you must first understand the core steps of the process itself. The limitations are not accidental; they are direct consequences of how a PM part is formed.

Tooling and Die Complexity

Powder metallurgy relies on pressing metal powder into a rigid die. This tooling is expensive to create and imposes geometric constraints on the final part.

Features like undercuts, cross-holes, or threads that are perpendicular to the direction of pressing are extremely difficult or impossible to produce directly.

Press Tonnage and Size Limitations

The force required to compact the powder uniformly is immense. The industry's largest presses are around 1,500 tons, which limits the practical size of a component.

This typically translates to a maximum planar surface area of 40 to 50 square inches. Anything larger becomes unfeasible with standard PM equipment.

The Nature of Sintering

After pressing, the fragile "green" compact is heated in a process called sintering. This heat treatment occurs below the metal's melting point.

Sintering bonds the metal particles together, giving the part its strength. However, because the metal is not fully melted, microscopic voids remain between the original particles.

The Impact on Material Properties

The physical constraints of the PM process directly influence the final mechanical properties of the component, which is the most critical consideration for any engineering application.

Reduced Strength and Ductility

The voids left after sintering result in inherent porosity. A PM part is never 100% dense like a forged or cast part.

This porosity acts as a stress concentration point, making PM parts generally less strong and less ductile (more brittle) than their wrought or cast iron counterparts.

Inherent Porosity

While porosity is a disadvantage for strength, it can be a planned feature for applications like self-lubricating bearings, where oil is held within the pores.

However, for structural components, this porosity is a critical limiting factor that must be accounted for in the design phase.

Understanding the Trade-offs: PM vs. Other Methods

No manufacturing process is perfect for every application. The disadvantages of PM become clear when compared directly against traditional alternatives like forging or casting.

When to Avoid PM for Strength

If your application demands the absolute highest tensile strength, fatigue resistance, and impact toughness, forging is the superior choice. The forging process creates a dense, wrought grain structure that is free of the porosity found in PM parts.

The Cost Factor: Tooling vs. Part Volume

The high upfront cost of creating the compaction die makes powder metallurgy uneconomical for low-volume production runs or prototypes.

PM only becomes cost-effective at high volumes where the tooling cost can be amortized over tens of thousands of parts. Machining or casting is often better for smaller quantities.

The Geometry and Size Barrier

If you need to produce a very large component or one with complex internal channels, undercuts, or other features not aligned with the pressing axis, casting is a far more suitable process. Casting allows for much greater design freedom and has significantly fewer size limitations.

Making the Right Choice for Your Application

Choosing the correct manufacturing process requires aligning your primary goal with the inherent strengths and weaknesses of each method.

- If your primary focus is maximum strength and impact resistance: Forging is almost always the superior choice due to its dense, porosity-free grain structure.

- If your primary focus is producing a small number of parts: The high initial tooling cost of PM makes machining from bar stock a more economical option.

- If your primary focus is a very large or geometrically intricate component: The size and shape limitations of PM make casting or fabrication a more practical solution.

Ultimately, understanding these disadvantages allows you to leverage powder metallurgy for what it does best: producing complex, high-precision parts at a massive scale when ultimate strength is not the single most critical factor.

Summary Table:

| Disadvantage | Impact on Final Part |

|---|---|

| Size Limitations | Max planar area of ~50 sq in due to press tonnage |

| Reduced Strength & Ductility | Inherent porosity from sintering lowers mechanical properties |

| High Tooling Cost | Economical only for high-volume production runs |

| Geometric Constraints | Difficult to produce undercuts, cross-holes, or threads |

Need help selecting the right manufacturing process for your lab components? At KINTEK, we specialize in providing high-quality lab equipment and consumables, helping you navigate material and process trade-offs to achieve optimal performance. Whether you're working with powder metallurgy parts or exploring alternatives, our expertise ensures you get durable, precise solutions tailored to your laboratory needs. Contact us today to discuss your project!

Visual Guide

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What are the key issues in the synthesis of nanomaterials? Overcoming Size, Shape, and Purity Control Challenges

- Does pyrolysis produce greenhouse gases? Discover Its Net Role in Reducing Emissions

- What is the difference between extruded and isostatic graphite? Choose the Right Material for Your Application

- Why is magnetron sputtering used? For High-Quality, High-Purity Thin Film Deposition

- What are the limitations and disadvantages of powder metallurgy? Understanding the Trade-Offs for Your Application

- What temp does THC bind with oil? Mastering the Two-Stage Process for Perfect Potency

- What is biomass conversion efficiency? Maximize Your Bioenergy Output and ROI

- How much more efficient are electric arc furnaces? Achieve 90% Energy Savings in Steel Production