In essence, annealing is a controlled heat treatment process that fundamentally alters a material's internal structure to make it more useful. The primary effects are the relief of internal stresses, an increase in ductility (the ability to deform without fracturing), and a general softening of the material, which often improves its machinability.

Annealing should be understood not as a single effect, but as a strategic "reset" for a metal's microstructure. It sacrifices hardness to gain ductility and relieve internal stress, making a material more workable and stable for subsequent manufacturing operations.

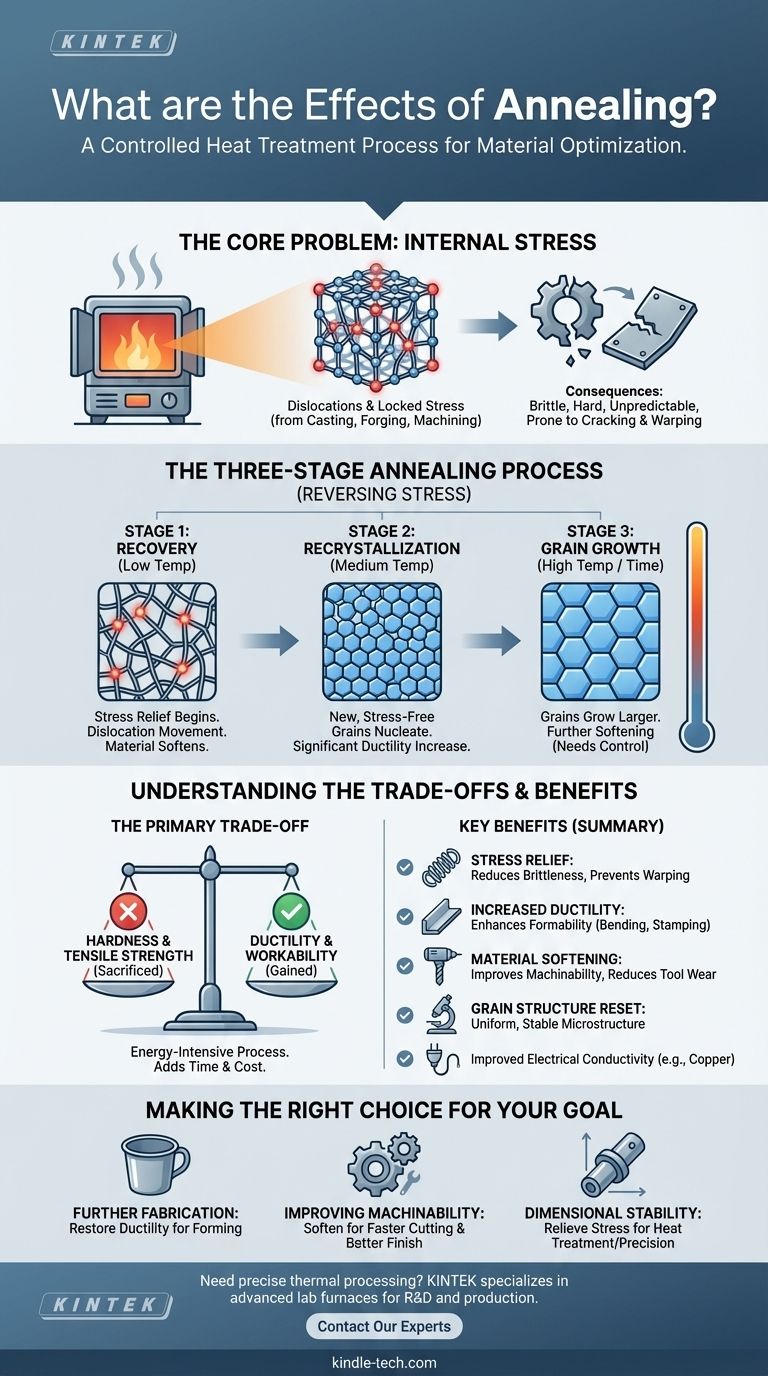

The Core Problem Annealing Solves: Internal Stress

Materials, particularly metals, accumulate internal stress and structural defects during manufacturing. Annealing is the primary method for reversing these undesirable changes.

Why Materials Build Up Stress

Processes like casting, forging, cold rolling, or even aggressive machining introduce enormous amounts of energy into a material. This energy deforms the metal's crystalline structure, creating a high density of defects called dislocations and locking in internal stress.

The Consequence of Internal Stress

A highly stressed material is brittle, harder, and less predictable. It is more prone to cracking when worked, resists cutting tools during machining, and can warp or distort unexpectedly during later processing steps, especially if subjected to more heat.

How Annealing Works: A Three-Stage Process

Annealing systematically reverses the effects of stress by heating the material to a specific temperature, holding it there, and then cooling it slowly. This process occurs in three distinct stages.

Stage 1: Recovery

At the lower end of the annealing temperature range, the material begins to recover. The added thermal energy allows internal stresses to be relieved as the tangled dislocations within the crystal structure begin to move and organize into lower-energy arrangements. The material becomes softer, but its core grain structure remains unchanged.

Stage 2: Recrystallization

As the temperature increases, the process of recrystallization begins. New, perfectly formed, stress-free grains start to nucleate and grow, gradually consuming the old, deformed grains created during fabrication. This stage is responsible for the significant increase in the material's ductility and is the most critical part of the process for restoring workability.

Stage 3: Grain Growth

If the material is held at the annealing temperature for too long, the new, stress-free grains will continue to grow larger. This can further soften the material and may be desirable for some applications, but must be carefully controlled. Excessively large grains can sometimes be detrimental to final part performance or surface finish.

Understanding the Trade-offs

While highly effective, annealing is not a universal solution and involves specific compromises. Understanding these is key to using the process correctly.

The Primary Trade-off: Hardness for Ductility

The most significant trade-off is sacrificing hardness and tensile strength to gain ductility. By relieving stress and recrystallizing the grain structure, you are making the material softer and easier to deform. This is the intended purpose, but it means the annealed material is not in its strongest state.

The Cost of Processing

Annealing is an energy-intensive process that requires specialized furnaces and precise temperature control. It adds both time and cost to the manufacturing workflow, so it should only be specified when its benefits are necessary for a successful outcome.

Improved Electrical Properties

In some metals, particularly copper, the removal of internal defects through annealing can also improve electrical conductivity. The uniform, stress-free crystal lattice offers less resistance to the flow of electrons.

Making the Right Choice for Your Goal

Apply annealing strategically based on the specific outcome you need for your component or material.

- If your primary focus is further fabrication (e.g., deep drawing, bending, or stamping): Anneal to restore ductility and prevent the material from cracking during forming operations.

- If your primary focus is improving machinability: Anneal to soften the material, which reduces tool wear, improves surface finish, and allows for faster cutting speeds.

- If your primary focus is dimensional stability: Anneal to relieve internal stresses from prior operations, preventing the part from warping or distorting during subsequent heat treatment or precision machining.

Ultimately, understanding the effects of annealing allows you to strategically control a material's properties to meet the demands of your design and manufacturing process.

Summary Table:

| Effect of Annealing | Key Benefit |

|---|---|

| Stress Relief | Reduces brittleness and prevents warping |

| Increased Ductility | Enhances formability for bending and stamping |

| Material Softening | Improves machinability and reduces tool wear |

| Grain Structure Reset | Creates a uniform, stable microstructure |

Need precise thermal processing for your materials? KINTEK specializes in advanced lab furnaces and thermal processing equipment. Whether you're working on R&D or production, our solutions ensure accurate annealing cycles for optimal material properties. Contact our experts today to discuss how we can enhance your laboratory's capabilities and improve your manufacturing outcomes.

Visual Guide

Related Products

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 1200℃ Muffle Furnace Oven for Laboratory

- Multi-zone Laboratory Tube Furnace

- Horizontal High Temperature Graphite Vacuum Graphitization Furnace

People Also Ask

- How does a sputtering machine work? Achieve Atomic-Level Precision for Your Coatings

- What is the boiling point of THC under a vacuum? A Guide to Safe Distillation

- What is the impact factor of powder metallurgy progress? A 2022 Analysis & Context

- What are the stages of sintering? A Guide to Mastering the Powder-to-Part Process

- What is sputtering technology? A Guide to Precision Thin Film Deposition