From an ethical standpoint, lab-grown diamonds offer a definitive advantage over many mined diamonds by guaranteeing a conflict-free, fully traceable origin. Because they are created in a controlled environment, they completely bypass the risks of funding conflict, human rights abuses, and child labor that have historically plagued parts of the natural diamond industry.

While physically and chemically almost identical to their mined counterparts, the true ethical value of a lab-grown diamond lies in its transparent and verifiable journey. It offers certainty in an industry where the origin of a stone can often be complex and obscure.

The Human Cost of Mined Diamonds

To understand the benefits of lab-grown diamonds, one must first understand the historical problems associated with diamond mining. The term "ethical" in this context primarily refers to human welfare.

The Problem of "Blood Diamonds"

Conflict diamonds, often called "blood diamonds," are stones mined in war-torn areas and sold to fund insurgency, warlord activities, or invasions.

These sales perpetuate violence and human rights abuses, directly linking the jewelry trade to immense human suffering in certain regions.

Labor Exploitation and Safety

Beyond active conflict zones, some diamond mining operations have been associated with severe labor exploitation, including the use of child labor.

Working conditions in unregulated mines are often extremely dangerous, lacking basic safety protocols and exposing workers to significant risk without fair compensation.

How Lab-Grown Diamonds Address Ethical Concerns

Lab-grown diamonds are created using technology that replicates the natural diamond-growing process. This manufacturing approach inherently solves the core ethical issues tied to mining.

Guaranteed Conflict-Free Origin

The single most important ethical benefit is that a lab-grown diamond is guaranteed to be conflict-free. Its origin is a specific laboratory, not a mine in a potentially unstable region.

This completely severs any possible connection between your purchase and the funding of armed conflict.

Full Traceability and Transparency

The supply chain for a lab-grown diamond is short, transparent, and fully traceable. You can know exactly where it was created, cut, and polished.

This stands in stark contrast to the often long and convoluted journey of a mined diamond, which can pass through many hands, making its ultimate origin difficult to verify with 100% certainty.

The Environmental Dimension of Ethical Choice

A comprehensive ethical evaluation also includes environmental responsibility. Lab-grown diamonds present a clear advantage by avoiding the significant ecological damage caused by mining.

Avoiding Environmental Degradation

Diamond mining is an intensive process that can cause irreversible environmental degradation. This includes soil erosion, deforestation, and the disruption of local ecosystems.

Creating a diamond in a lab eliminates the need for digging vast pits or caves, leaving the earth's surface and vegetation undisturbed.

A Significantly Smaller Carbon Footprint

The energy required to create a diamond in a lab results in a much smaller carbon footprint than mining.

Some analyses show the lab process produces hundreds of times less carbon than unearthing a natural diamond, which relies on heavy machinery and extensive transportation networks.

Understanding the Trade-offs

While the ethical and environmental case is strong, it is crucial to approach the decision with a full understanding of what lab-grown diamonds are and are not.

Value and Rarity

Natural diamonds are valued for their geological rarity, a quality that lab-grown diamonds, which can be produced in unlimited quantities, do not possess.

Consequently, lab-grown diamonds have a lower resale value and are considered less valuable overall. They are more accessible, often costing 20% to 70% less than a mined diamond of identical quality and size.

Market Perception

While physically and visually identical to the naked eye, some consumers still place a premium on the tradition and natural origin of a mined diamond. The choice often comes down to personal values.

Lab-grown diamonds are also used extensively for industrial purposes, such as in cutting tools and abrasives, which is their primary application by volume.

Making the Right Choice for Your Goal

Your final decision should align with your personal priorities.

- If your primary focus is ethical certainty and transparency: A lab-grown diamond is the superior choice, as its conflict-free origin is verifiable and absolute.

- If your primary focus is environmental impact: The smaller carbon footprint and lack of mining make lab-grown diamonds a more sustainable option.

- If your primary focus is maximizing budget and size: Lab-grown diamonds offer a visually stunning, high-quality stone for a significantly lower price.

- If your primary focus is traditional romance, rarity, and long-term value: A natural diamond from a verifiably ethical source remains the traditional standard.

Ultimately, choosing a lab-grown diamond allows you to make a conscious, informed decision that aligns with modern ethical and environmental values.

Summary Table:

| Ethical Aspect | Lab-Grown Diamonds | Mined Diamonds (Risks) |

|---|---|---|

| Conflict-Free Origin | Guaranteed | Risk of funding conflict ("blood diamonds") |

| Labor Practices | Controlled, safe environment | Risk of exploitation & unsafe conditions |

| Supply Chain Transparency | Fully traceable | Often complex and obscure |

| Environmental Impact | Smaller carbon footprint, no mining | Significant ecological degradation |

Make an informed, ethical choice for your laboratory or business.

At KINTEK, we understand that your needs extend beyond product specifications to encompass ethical sourcing and environmental responsibility. Whether you require lab-grown diamonds for cutting-edge research, industrial applications, or high-precision tools, we provide high-quality, verifiable materials that align with your values.

Partner with KINTEK to ensure your materials are:

- Ethically Sourced: Guaranteed conflict-free and transparently supplied.

- Environmentally Responsible: Reduce your carbon footprint with a sustainable alternative.

- Cost-Effective: Access high-performance materials at a lower cost.

Let us help you integrate ethical excellence into your work. Contact our experts today to discuss your specific lab equipment and consumable needs.

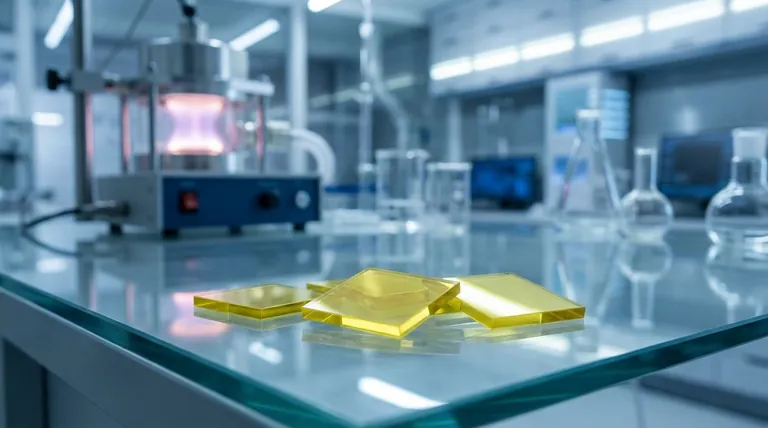

Visual Guide

Related Products

- CVD Diamond for Thermal Management Applications

- CVD Diamond Dressing Tools for Precision Applications

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- CVD Diamond Domes for Industrial and Scientific Applications

- CVD Diamond Optical Windows for Lab Applications

People Also Ask

- What is the process of MPCVD? Grow High-Purity Diamond & Advanced Films

- What is a microwave plasma source? A Key Tool for Advanced Materials and Manufacturing

- How does the power adjustment of a microwave generator affect the structural properties of coatings? | KINTEK

- Can a diamond tester tell the difference between lab grown and natural diamonds? The Surprising Truth

- What are diamond films used for? Enhancing Tools, Electronics, and Implants with Diamond Surfaces

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers

- What is the function of the vacuum pump system during high-pressure MPCVD for DLC films? Optimize Purity and Stability

- What are the industrial uses of CVD diamond? Unlock Extreme Performance in Your Applications