At its core, the sintering process is governed by five critical factors: temperature, time, pressure, particle characteristics, and material composition. These elements work in concert to transform a loose powder into a dense, solid part by driving atomic diffusion at temperatures below the material's melting point. Mastering this interplay is essential for controlling the final properties of any sintered component.

Sintering is not merely about heating a material. It is a precisely controlled balancing act where you manipulate temperature, pressure, and time to manage the atomic-level fusion of particles, which ultimately determines the final microstructure, density, and strength of your component.

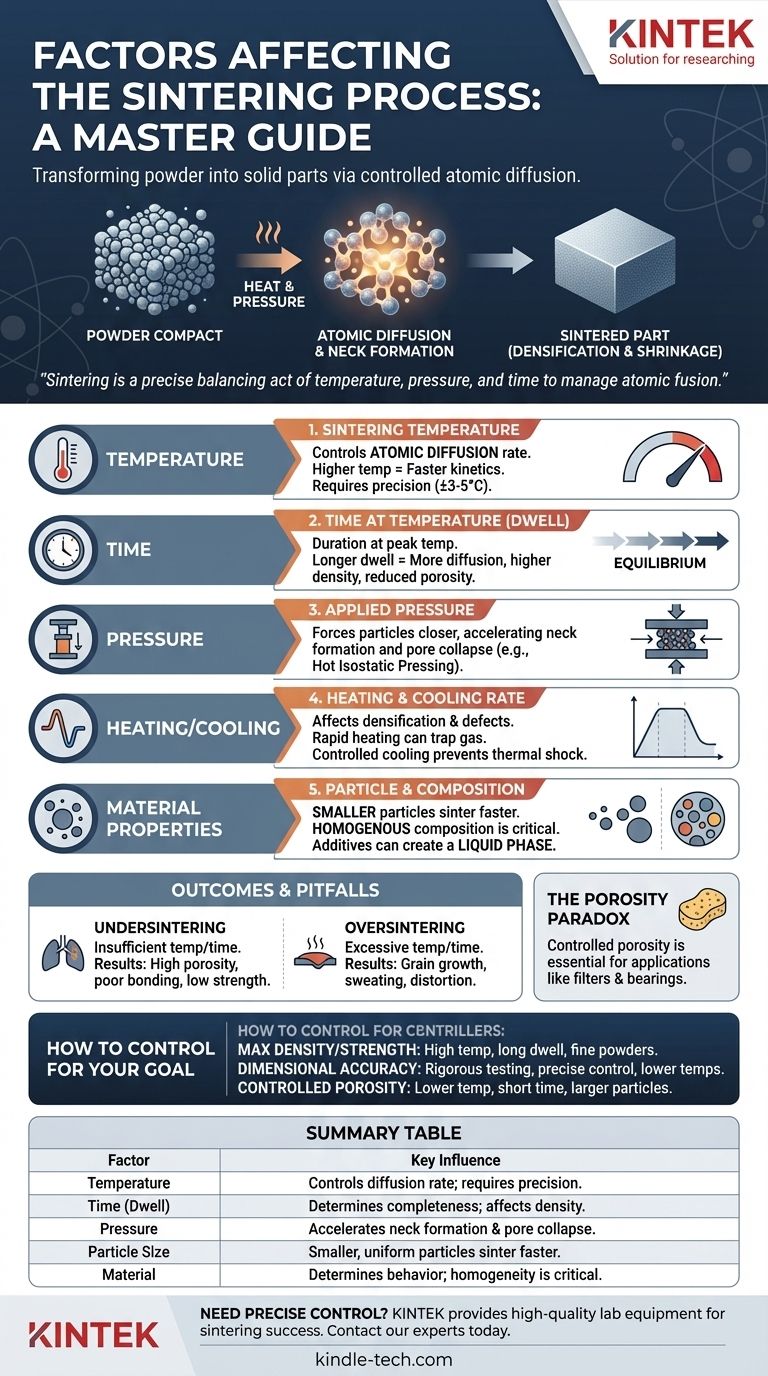

The Core Sintering Mechanism: A Quick Primer

What is Sintering?

Sintering is a thermal process that bonds adjacent particles in a powder compact, increasing its strength and density. This happens without melting the bulk of the material.

The Driving Force

The primary driving force is the reduction of surface energy. Small, individual particles have a vast amount of surface area. By fusing together and forming "necks" between them, the system lowers its total energy, creating a more stable, solid mass.

The Mechanism of Action

This fusion occurs through atomic diffusion. At high temperatures, atoms migrate across the contact points between particles, filling the voids (pores) and causing the particles to merge. This process is what causes the part to densify and shrink.

The Primary Control Factors in Sintering

Sintering Temperature

Temperature is the most dominant factor, as it directly controls the rate of atomic diffusion. Higher temperatures dramatically accelerate the sintering kinetics.

However, control is paramount. The required temperature is often extremely precise, with acceptable variations as narrow as ±3°C to 5°C to achieve consistent results.

Time at Temperature (Dwell Time)

This refers to the duration the material is held at the peak sintering temperature. A longer dwell time allows for more complete diffusion, leading to higher density and reduced porosity.

Sufficient time is necessary for the atomic migration to reach an equilibrium state for the given temperature.

Applied Pressure

Pressure enhances the sintering process by forcing particles into closer contact, which accelerates neck formation and helps collapse pores.

This can be applied during the initial powder compaction stage or during the heating process itself (e.g., in pressure sintering or hot isostatic pressing). This mechanical force aids the thermal driving force.

Heating and Cooling Rate

The rate at which the material is heated affects densification and can introduce defects. A rapid heating rate can trap gases within the part, leading to bloating or blistering.

Similarly, a controlled cooling rate is essential to prevent thermal shock and cracking, ensuring the final part's structural integrity.

The Influence of Material Properties

Particle Size and Distribution

Smaller particles sinter faster and at lower temperatures than larger ones. This is because they have a higher surface-area-to-volume ratio, which provides a greater driving force for densification.

A uniform particle size distribution promotes more even shrinkage and a more homogeneous final microstructure.

Powder Composition and Homogeneity

The chemical composition of the powder is fundamental. In alloys, ensuring the elements are homogeneously mixed is critical for consistent properties.

In some cases, specific additives or a secondary material with a lower melting point are used to create a liquid phase during sintering, which can dramatically accelerate the densification process.

Understanding Sintering Outcomes and Pitfalls

Undersintering vs. Oversintering

Undersintering occurs when the temperature or time is insufficient. The result is a part with high porosity, poor particle bonding, and low mechanical strength.

Oversintering happens when the temperature or time is excessive. This can lead to excessive grain growth, which can paradoxically weaken the material. In extreme cases, it can cause "sweating" (localized melting) or distortion.

The Porosity Paradox

While the goal is often to eliminate porosity for maximum density and strength, some applications require it. Sintering is unique in its ability to create parts with controlled, interconnected porosity.

This is critical for products like self-lubricating bearings and filters, where the pores are a functional part of the design.

Dimensional Precision

Sintering almost always involves shrinkage as pores are eliminated. Controlling all the primary factors—temperature, time, particle size—is absolutely essential to predict and manage this shrinkage to produce a dimensionally accurate final part.

How to Control the Sintering Process for Your Goal

The optimal parameters depend entirely on the desired outcome for the final component.

- If your primary focus is maximum density and strength: Prioritize higher temperatures, longer dwell times, and the use of fine, uniform powders to minimize final porosity.

- If your primary focus is high dimensional accuracy: Conduct rigorous testing to precisely correlate temperature and time with shrinkage, often using slightly lower temperatures to gain finer control.

- If your primary focus is creating controlled porosity (e.g., for filters): Use lower temperatures, shorter times, and potentially larger or irregularly shaped particles to intentionally halt the densification process and preserve an open pore network.

Ultimately, mastering the sintering process is about understanding that you are not just shaping a part, but engineering its internal microstructure.

Summary Table:

| Factor | Key Influence on Sintering |

|---|---|

| Temperature | Controls atomic diffusion rate; requires precise control (±3-5°C). |

| Time (Dwell) | Determines completeness of diffusion; affects final density. |

| Pressure | Forces particles closer, accelerating neck formation and pore collapse. |

| Particle Size/Shape | Smaller, uniform particles sinter faster and more evenly. |

| Material Composition | Determines sintering behavior; homogeneity is critical for alloys. |

Need precise control over your sintering process?

KINTEK specializes in providing the high-quality lab equipment and consumables necessary to master these critical sintering factors. Whether your goal is maximum density, dimensional accuracy, or controlled porosity, our expertise and products can help you achieve consistent, high-quality results.

Contact our experts today to discuss your specific sintering challenges and how we can support your laboratory's success.

Visual Guide

Related Products

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- Spark Plasma Sintering Furnace SPS Furnace

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Horizontal High Temperature Graphite Vacuum Graphitization Furnace

People Also Ask

- What temperature does titanium vaporize at? Unlocking Its Extreme Heat Resistance for Aerospace

- What are the stages of sintering? A Guide to Mastering the Powder-to-Part Process

- What is the purpose of using vacuum-sealed glass tubes for Thio-LISICON sintering? Optimize Solid Electrolyte Purity

- How does a sputtering machine work? Achieve Atomic-Level Precision for Your Coatings

- What is sputtering technology? A Guide to Precision Thin Film Deposition