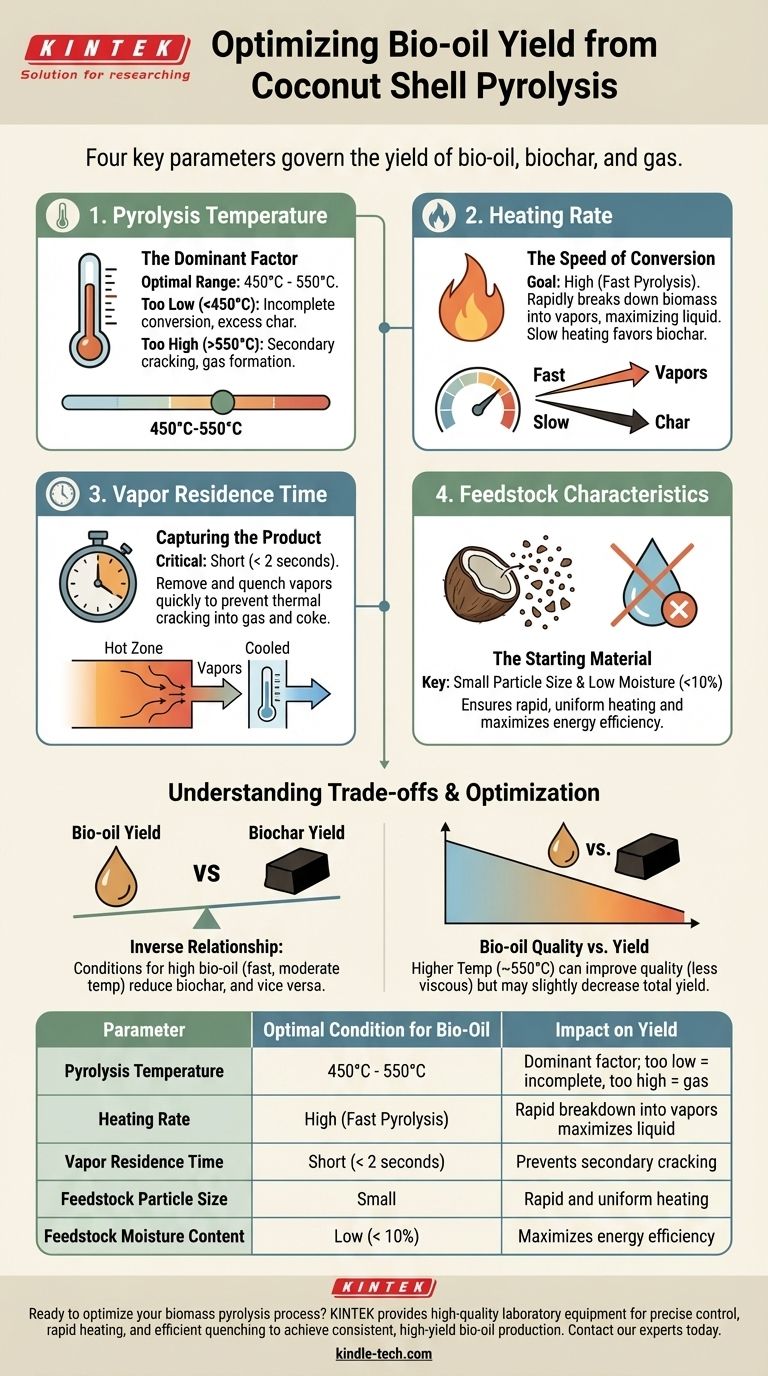

Ultimately, four key process parameters govern the yield of bio-oil from the pyrolysis of coconut shells: pyrolysis temperature, heating rate, vapor residence time, and the physical characteristics of the feedstock itself. While all are important, controlling the temperature and heating rate provides the most significant leverage over the final product distribution.

The core challenge in producing bio-oil is not just heating the coconut shell, but controlling the speed and duration of that heat. Maximizing liquid yield requires a rapid thermal breakdown of the biomass and immediate cooling of the resulting vapors to prevent them from further decomposing into gas.

Key Pyrolysis Parameters Influencing Bio-oil Yield

To effectively convert coconut shells into bio-oil, you must manage a delicate balance between several interconnected variables. Each one plays a distinct role in determining whether you produce primarily liquid (bio-oil), solid (biochar), or gas.

Pyrolysis Temperature: The Dominant Factor

Temperature is the single most influential parameter. It dictates the extent of the biomass decomposition.

For bio-oil production from coconut shells, the optimal temperature range is typically 450°C to 550°C. Below this range, the conversion is incomplete, leaving behind excess char. Above this range, secondary cracking of the vapors occurs, breaking down the valuable liquids into non-condensable gases and reducing your bio-oil yield.

Heating Rate: The Speed of Conversion

The heating rate determines which chemical pathways are favored during pyrolysis.

To maximize bio-oil, a high heating rate is essential. This process, known as fast pyrolysis, rapidly breaks down the cellulose, hemicellulose, and lignin in the coconut shell into vapors. Slow heating rates, by contrast, favor the formation of solid biochar.

Vapor Residence Time: Capturing the Product

This refers to how long the hot pyrolysis vapors remain in the high-temperature reactor zone.

A short vapor residence time is critical for high bio-oil yield. The goal is to remove the vapors from the hot reactor and cool them (quench) as quickly as possible—typically in less than two seconds. If vapors linger in the hot zone, they will thermally crack into lower value gases and solid coke, decreasing the final liquid yield.

Feedstock Characteristics: The Starting Material

The initial state of the coconut shell feedstock has a significant impact on the efficiency of the process.

Two primary characteristics matter: particle size and moisture content. Smaller particles heat up more quickly and uniformly, favoring the rapid reactions needed for bio-oil. Likewise, low moisture content (typically below 10%) is crucial, as the energy required to evaporate water is wasted and does not contribute to the pyrolysis reaction.

Understanding the Trade-offs: Bio-oil vs. Biochar vs. Gas

Optimizing for one product inherently means de-emphasizing the others. Understanding this relationship is fundamental to process control and achieving your desired outcome.

The Product Yield Dilemma

There is an inverse relationship between bio-oil and biochar yields.

Conditions that favor high bio-oil yield (fast heating, moderate temperature) necessarily result in lower biochar yield. Conversely, conditions designed to maximize biochar (slow heating, wider temperature range) will produce very little bio-oil.

Bio-oil Quality Considerations

Maximizing yield does not always mean maximizing quality.

Running the process at the higher end of the optimal temperature range (e.g., 550°C) may slightly decrease the total liquid yield due to some gas formation, but it can also improve the quality of the bio-oil by reducing its viscosity and water content. This is a critical operational trade-off to consider.

Optimizing Your Process for Bio-oil

Your ideal set of parameters depends entirely on your primary goal. Use these guidelines to steer your operational strategy.

- If your primary focus is maximizing bio-oil yield: Target a rapid heating rate with a peak temperature of ~500°C and ensure vapor residence time is under two seconds.

- If your primary focus is a balanced output of bio-oil and biochar: Utilize a slower heating rate and a slightly lower temperature (~400-450°C), which will increase char formation at the expense of some liquid.

- If your primary focus is producing a higher quality (less viscous) bio-oil: Operate near the upper end of the optimal temperature range (~550°C), accepting a slightly lower overall liquid yield.

Mastering these factors empowers you to precisely control the pyrolysis process and transform coconut shell waste into your desired valuable product.

Summary Table:

| Parameter | Optimal Condition for Bio-Oil | Impact on Yield |

|---|---|---|

| Pyrolysis Temperature | 450°C - 550°C | Dominant factor; too low = incomplete conversion, too high = gas formation |

| Heating Rate | High (Fast Pyrolysis) | Rapid breakdown of biomass into vapors maximizes liquid yield |

| Vapor Residence Time | Short (< 2 seconds) | Prevents secondary cracking of vapors into gas |

| Feedstock Particle Size | Small | Ensures rapid and uniform heating |

| Feedstock Moisture Content | Low (< 10%) | Maximizes energy efficiency for pyrolysis reactions |

Ready to optimize your biomass pyrolysis process?

At KINTEK, we specialize in providing high-quality laboratory equipment and consumables for advanced research and development. Whether you are scaling up bio-oil production or refining your pyrolysis parameters, our expertise can help you achieve precise temperature control, rapid heating rates, and efficient vapor quenching.

We help you:

- Achieve consistent and high-yield bio-oil production.

- Select the right equipment for your specific feedstock and goals.

- Improve the quality and value of your bio-based products.

Contact our experts today to discuss how our solutions can enhance your laboratory's capabilities. Let's turn your biomass into valuable products together.

Get in Touch with KINTEK for a Consultation

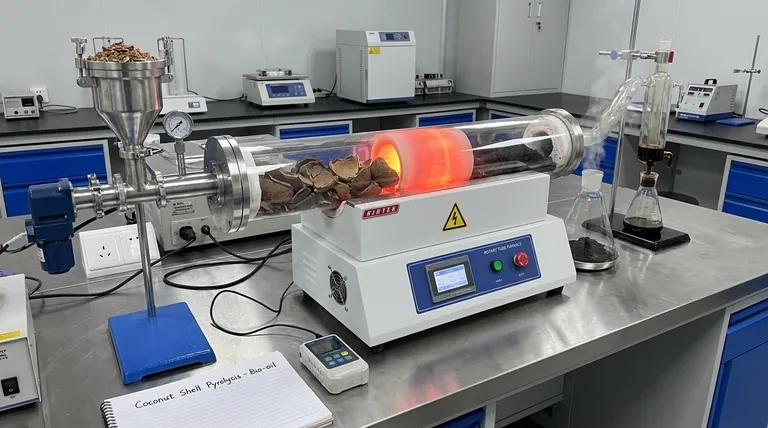

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why are high temperatures required when sintering stainless steels? Unlock Pure, High-Density Results

- What are the equipment requirements for loading platinum (Pt) onto composite supports? Precise Stirring for High Dispersion

- What are the characteristics of the slipping, slumping, and rolling modes of bed motion? Optimize Your Rotary Process

- What are the process advantages of using a rotary tube furnace for WS2 powder? Achieve Superior Material Crystallinity

- What temperature is needed for pyrolysis waste? A Guide to Optimizing Your Waste-to-Value Process