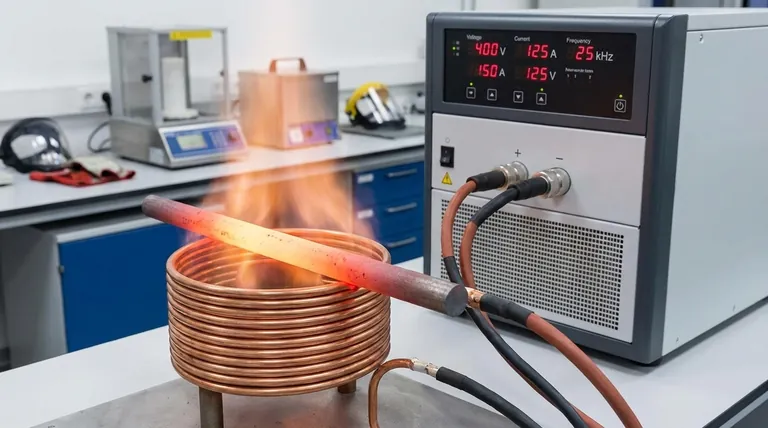

In short, heat generation in induction heating depends on the amount of induced current, the electrical resistance of the workpiece, and the duration of the heating. This process is governed by a fundamental principle known as the Joule effect, where electrical currents (called eddy currents) flowing through a material generate heat as they overcome the material's resistance.

The core challenge of induction heating is not simply generating heat, but precisely controlling it. This control is achieved by manipulating the induction coil's power and frequency to influence the induced currents, while accounting for the specific physical properties of the material being heated.

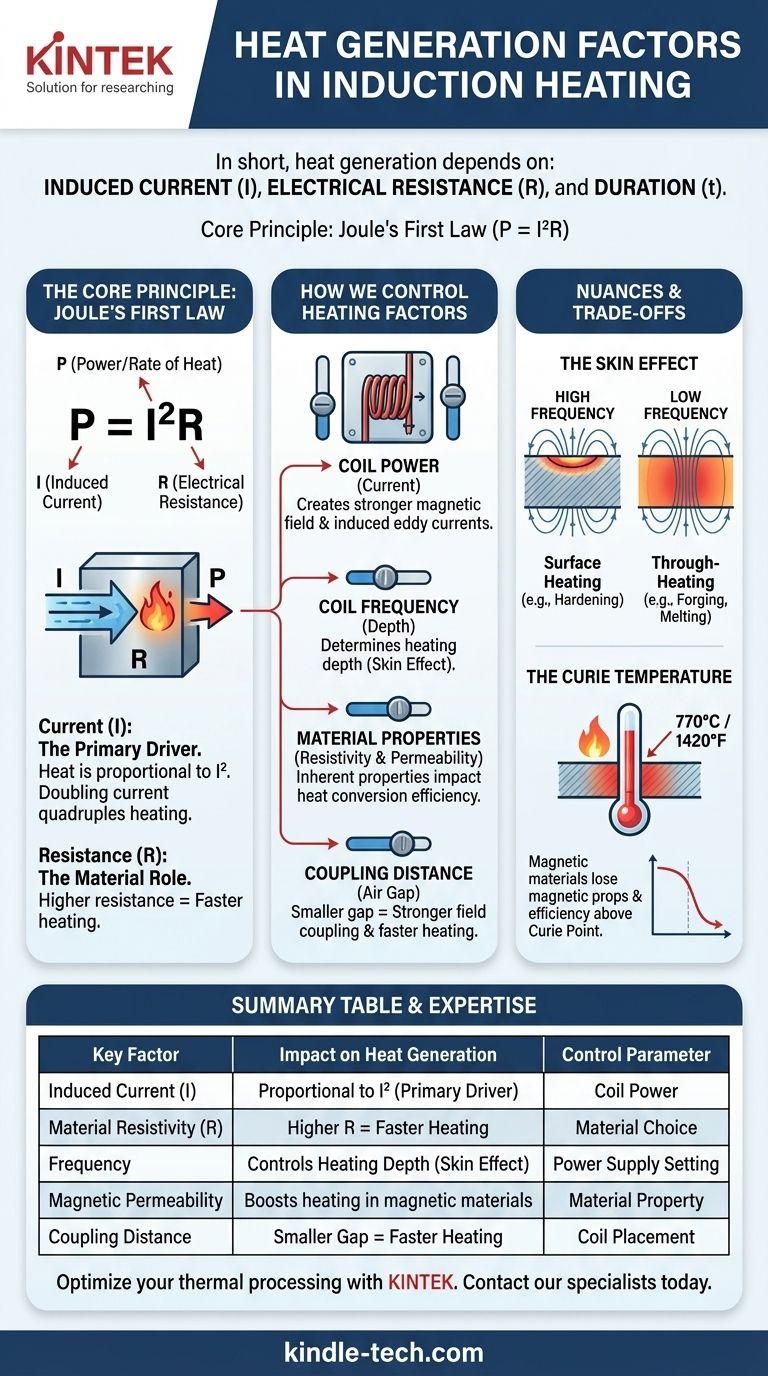

The Core Principle: Joule's First Law

At its heart, induction heating is a direct application of fundamental physics. The amount of heat generated is a product of current, resistance, and time.

The Equation of Heat

The power, or rate of heat generation, is defined by the formula P = I²R. Here, P is power (heat per second), I is the current flowing through the material, and R is the material's electrical resistance.

Current (I): The Primary Driver

The most significant factor is the induced eddy current. Because the heat generated is proportional to the square of the current, doubling the induced current will quadruple the rate of heating.

Resistance (R): The Material's Role

The electrical resistance (or more specifically, the resistivity) of the workpiece determines how effectively the eddy currents are converted into heat. Materials with higher resistance will heat up more quickly for the same amount of current.

How We Control the Heating Factors

While you cannot directly "set" the eddy currents or the material's resistance, you control them indirectly through the induction system's parameters. These are the practical levers you can adjust.

The Induction Coil's Power and Frequency

The current flowing through the work coil creates a powerful, alternating magnetic field. A higher current in the coil induces a stronger magnetic field and, consequently, stronger eddy currents in the workpiece, leading to more rapid heating.

The frequency of the alternating current is equally critical. It determines where in the part the heat is generated, a phenomenon known as the skin effect.

The Workpiece's Material Properties

A material's inherent resistivity directly impacts its ability to generate heat. Materials like steel have higher resistivity than copper, making them much easier to heat with induction.

For magnetic materials like carbon steel, magnetic permeability plays a huge role. High permeability concentrates the magnetic field, dramatically increasing the induced current and heating effect.

The Coupling Distance (Air Gap)

This refers to the physical distance between the induction coil and the workpiece. A smaller gap results in a stronger magnetic field coupling, which induces more current and leads to more efficient and faster heating.

Understanding the Trade-offs and Nuances

Mastering induction heating requires understanding how these factors interact, often in non-linear ways.

The Skin Effect

Higher frequencies cause the eddy currents to flow in a thin layer near the surface of the workpiece. This is ideal for applications like surface hardening.

Lower frequencies allow the magnetic field to penetrate deeper into the part, generating heat more uniformly throughout its cross-section. This is necessary for through-heating billets before forging or for melting applications.

The Curie Temperature

Magnetic materials like steel lose their magnetic properties above a specific temperature, known as the Curie point (around 770°C or 1420°F).

When a part passes its Curie temperature, its permeability drops dramatically. This reduces the efficiency of the heating process, and the induction power supply must be able to compensate to continue heating the now non-magnetic material.

Coil Design and Geometry

The shape, size, and number of turns in the coil are critical. The coil must be designed to match the geometry of the workpiece to deliver a uniform magnetic field and, therefore, uniform heating to the target area.

Making the Right Choice for Your Goal

The optimal settings depend entirely on your desired outcome.

- If your primary focus is surface hardening a steel gear: Use a high frequency to concentrate heat on the surface, coupled with high power for a very short duration.

- If your primary focus is through-heating a large aluminum billet: Use a lower frequency for deep penetration and a longer heating time to allow the heat to equalize throughout the material.

- If your primary focus is melting steel in a crucible: Use a low-to-medium frequency to ensure deep penetration and induce a magnetic stirring effect, combined with high, sustained power.

By understanding these core factors, you can move from brute-force heating to precise and efficient thermal processing.

Summary Table:

| Key Factor | Impact on Heat Generation | Control Parameter |

|---|---|---|

| Induced Current (I) | Heat is proportional to I² (primary driver) | Coil Power |

| Material Resistivity (R) | Higher resistance = faster heating | Material Choice |

| Frequency | Controls heating depth (skin effect) | Power Supply Setting |

| Magnetic Permeability | Boosts heating in magnetic materials (e.g., steel) | Material Property |

| Coupling Distance | Smaller gap = stronger field & faster heating | Coil Workpiece Placement |

Ready to apply this knowledge and achieve precise, efficient heating in your lab or production line?

KINTEK specializes in high-performance lab equipment and consumables, including induction heating systems tailored for applications like surface hardening, through-heating, and melting. Our experts can help you select the right equipment and settings to optimize your thermal processing, saving you time and energy.

Contact our thermal processing specialists today to discuss your specific needs and discover the KINTEK advantage.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Anti-Cracking Press Mold for Lab Use

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Engineering Advanced Fine Ceramics Aluminum Oxide Al2O3 Heat Sink for Insulation

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is SiC melting point? Discover the Extreme Thermal Stability of Silicon Carbide

- What is SiC elements? The Ultimate High-Temperature Heating Solution

- What is the maximum temperature for a SiC heating element? Unlock the Key to Longevity and Performance

- What kind of metal is used in heating elements? A Guide to Materials for Every Temperature & Atmosphere

- What are silicon carbide heating elements used for? Reliable High-Temp Heating for Industrial Processes