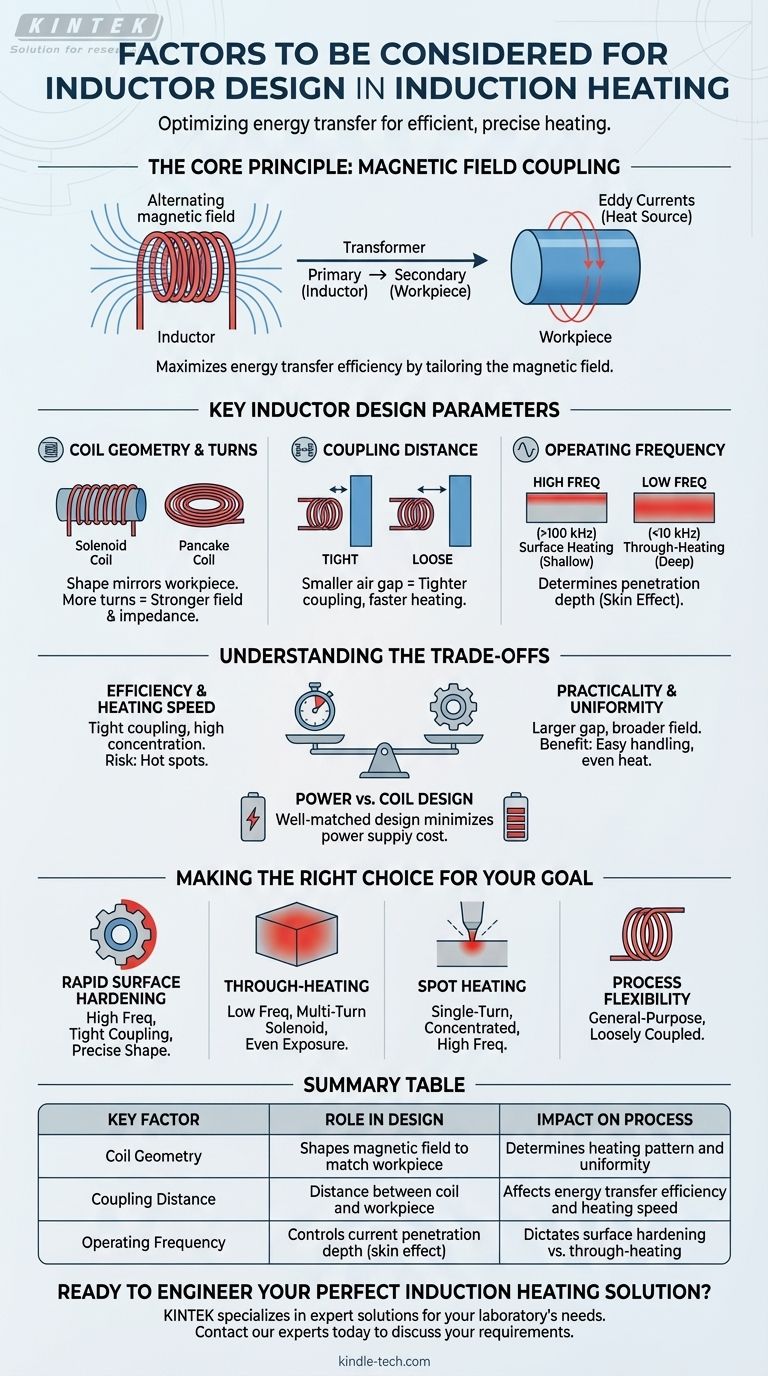

At its core, inductor design for induction heating revolves around three critical factors: the geometry of the coil, the coupling distance between the coil and the workpiece, and the operating frequency of the power supply. These elements work together to create a magnetic field that efficiently transfers energy into the part you intend to heat.

Your inductor is not just a coil of copper; it is the primary winding of a transformer where your workpiece is the secondary. The goal is to maximize the efficiency of this energy transfer by carefully tailoring the magnetic field to the specific material, shape, and heating requirements of your application.

The Core Principle: Magnetic Field Coupling

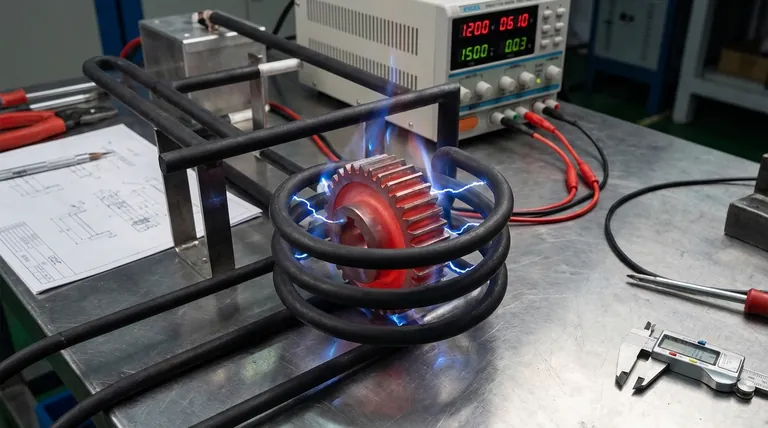

Induction heating works by generating a powerful, alternating magnetic field within a copper coil (the inductor). When a conductive workpiece is placed inside this field, it induces electrical currents—known as eddy currents—within the part itself. The material's resistance to these currents is what generates precise, internal heat.

The Role of the Inductor

The inductor's job is to shape and concentrate this magnetic field. Think of it as a broadcast antenna, but for energy. Its shape, size, and number of turns dictate the pattern and intensity of the magnetic field it produces.

The Workpiece as Part of the Circuit

The workpiece is not a passive bystander; it is an active component in the electrical circuit. The efficiency of the entire system depends on how well the magnetic field from the inductor "couples" with the workpiece to induce strong eddy currents.

Key Inductor Design Parameters

Mastering inductor design means understanding how to manipulate a few key variables to achieve your desired heating profile.

Coil Geometry and Number of Turns

The shape of the inductor should mirror the shape of the area you want to heat. A simple solenoid (cylindrical) coil is used for heating rods or shafts, while a "pancake" coil might be used for heating a flat surface.

The number of turns in the coil is also critical. More turns generally create a stronger magnetic field but also increase the inductor's impedance, which must be matched to the power supply.

Coupling Distance

Coupling refers to the proximity of the inductor to the workpiece. The strength of the magnetic field decreases dramatically with distance. A smaller air gap results in tighter coupling, more efficient energy transfer, and faster heating.

Operating Frequency

Frequency is one of the most powerful variables in induction heating. It determines the depth to which the eddy currents penetrate the workpiece, a phenomenon known as the skin effect.

- High Frequencies (e.g., >100 kHz): Create shallow currents, concentrating heat on the surface of the part. This is ideal for surface hardening.

- Low Frequencies (e.g., <10 kHz): Create deeper currents, allowing for uniform "through-heating" of larger parts.

Understanding the Trade-offs

Every design choice involves a compromise. True expertise lies in balancing these competing factors to meet the project's primary goal.

Efficiency vs. Practicality

The most electrically efficient design would be a coil wrapped tightly around the workpiece with almost no air gap. However, this is often impractical. You must allow enough space for easy insertion and removal of the part, especially in an automated production line.

Heating Speed vs. Uniformity

A highly concentrated magnetic field will heat a specific area very rapidly. This can be desirable, but it can also create hot spots and thermal stress. A less-intense, broader field may heat more slowly but will produce a much more uniform temperature throughout the part.

Power Requirements vs. Coil Design

A poorly designed inductor is inefficient and will require a much larger, more expensive power supply to deliver the necessary heat into the part. A well-matched inductor transfers energy effectively, allowing you to achieve your heating goals with the minimum required power.

Making the Right Choice for Your Goal

Your inductor design should be driven by the intended outcome. Consider your primary objective and select the appropriate design philosophy.

- If your primary focus is rapid surface hardening: Use a high frequency, a coil that is tightly coupled (close to the part), and a shape that precisely mirrors the target surface.

- If your primary focus is through-heating a large part: Use a lower frequency and a multi-turn solenoid coil that provides even magnetic field exposure over the entire part.

- If your primary focus is heating a small, specific spot: Use a single-turn, highly concentrated coil with a high frequency to focus the energy exactly where it is needed.

- If your primary focus is process flexibility: Design a more general-purpose, loosely coupled coil, accepting that it will be less efficient than a custom-designed inductor.

By understanding these fundamental principles, you can move beyond simple trial-and-error and begin to engineer induction coils with precision and intent.

Summary Table:

| Key Factor | Role in Design | Impact on Process |

|---|---|---|

| Coil Geometry | Shapes the magnetic field to match the workpiece | Determines heating pattern and uniformity |

| Coupling Distance | Distance between coil and workpiece | Affects energy transfer efficiency and heating speed |

| Operating Frequency | Controls current penetration depth (skin effect) | Dictates surface hardening vs. through-heating |

Ready to Engineer Your Perfect Induction Heating Solution?

Choosing the right inductor design is critical for achieving precise, efficient, and repeatable heating results. KINTEK specializes in lab equipment and consumables, providing expert solutions for your laboratory's induction heating needs. Our team can help you select or design the ideal inductor to maximize your process efficiency, whether you're focused on surface hardening, through-heating, or specialized applications.

Contact our experts today to discuss your specific requirements and discover how KINTEK can enhance your laboratory's capabilities.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Cylindrical Lab Electric Heating Press Mold for Laboratory Applications

- Silicon Carbide (SIC) Ceramic Sheet Flat Corrugated Heat Sink for Engineering Advanced Fine Ceramics

- Square Bidirectional Pressure Mold for Lab Use

- Oxygen Probe to Measure Temperature and Active Oxygen Content in Molten Steel

People Also Ask

- What is SiC melting point? Discover the Extreme Thermal Stability of Silicon Carbide

- What is the maximum temperature for a SiC heating element? Unlock the Key to Longevity and Performance

- What is silicon carbide rod heated to high temperature used as? A Premier Heating Element for Extreme Environments

- What is the maximum temperature for silicon carbide heating element? The Real Limit for Your High-Temp Furnace

- What material is used for making heating element? Choose the Right Alloy for Your Application