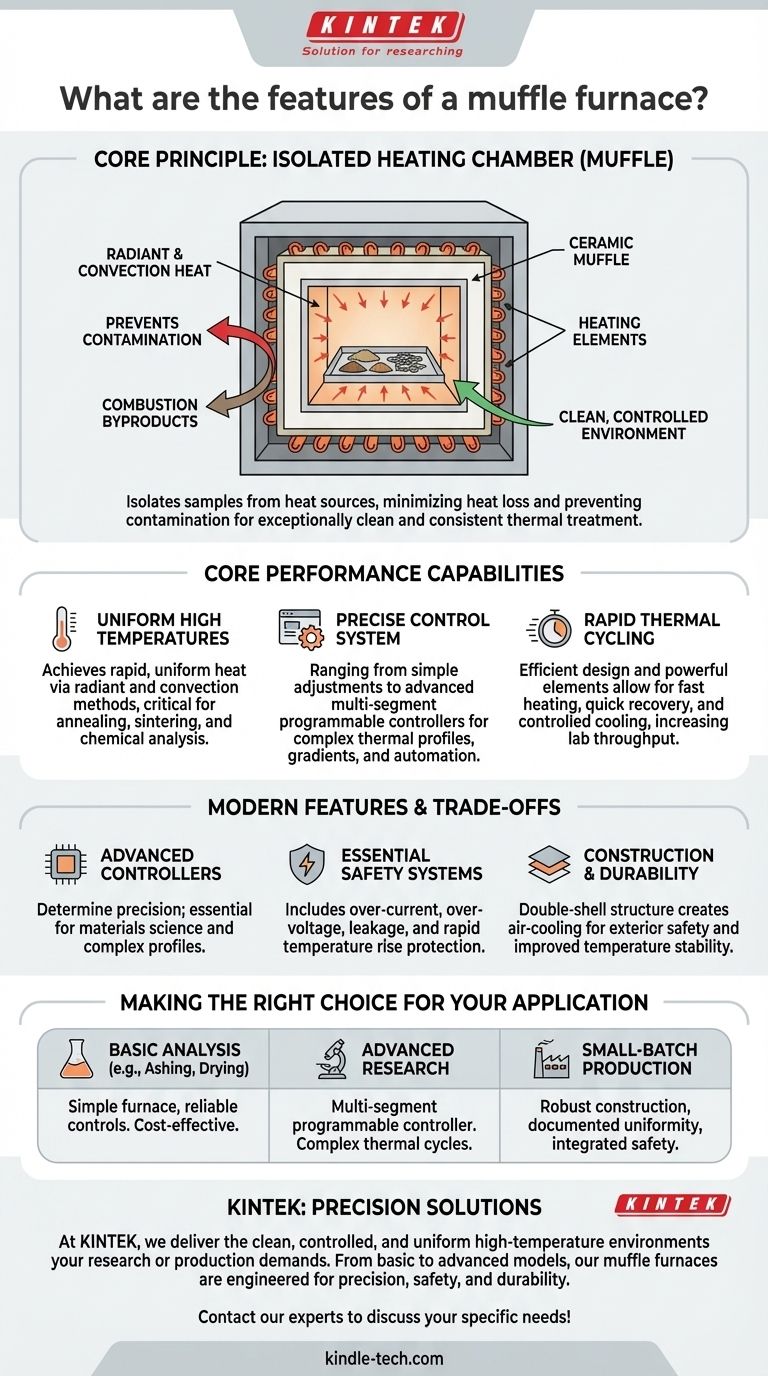

At its core, a muffle furnace is defined by three primary features: an isolated heating chamber that separates the material from the heat source, the ability to achieve rapid and uniform high temperatures, and a precise control system. This design ensures that the material being heated remains uncontaminated by combustion byproducts or direct contact with the heating elements.

The essential purpose of a muffle furnace is not simply to generate heat, but to create an exceptionally clean, controlled, and uniform high-temperature environment. Its key feature—the isolated chamber or "muffle"—is what makes this precision possible.

The Defining Principle: Isolated Heating

The most fundamental feature of a muffle furnace is the physical separation between the heat source and the material being processed. This is accomplished by the "muffle" itself.

What is the "Muffle"?

The muffle is an inner chamber, typically made of high-temperature refractory material like ceramic. This chamber houses the samples and acts as a barrier, preventing direct contact with the heating elements.

This insulated material also minimizes heat loss, contributing to the furnace's energy efficiency and ability to maintain stable temperatures.

Preventing Contamination

In traditional fuel-fired furnaces, byproducts of combustion can contaminate the materials being heated. A muffle furnace’s sealed chamber design prevents these contaminants from ever reaching the sample.

In modern electric muffle furnaces, this feature is even more pronounced. Since there is no combustion, the primary goal is to isolate the sample from the heating elements themselves, which could otherwise degrade or react with the material.

Ensuring Uniform Heat

The chamber is designed to heat materials homogeneously. It uses a combination of radiant heat from the chamber walls and convection heat from the air inside.

This ensures the entire workpiece receives a consistent thermal treatment, which is critical for applications like annealing, sintering, or chemical analysis.

Core Performance Capabilities

Beyond its basic structure, a muffle furnace is characterized by its performance, which is dictated by its heating elements and control system.

High-Temperature Operation

Muffle furnaces are designed for rapid, high-temperature work. They often use powerful electric heating elements such as resistance wires, silicon carbon rods, or silicon-molybdenum rods to achieve their target temperatures quickly.

Advanced Temperature Control

The control system is a critical feature. Basic models allow for simple temperature and time adjustments.

More advanced furnaces feature sophisticated, multi-segment programmable controllers. These systems allow users to design complex heating and cooling cycles, plan thermal gradients, and even automate experiments with remote control capabilities.

Rapid Thermal Cycling

An efficient cabinet design combined with powerful heating elements allows for rapid heating, temperature recovery after opening the door, and controlled cooling. This capability is essential for both research and small-batch production environments where time is a factor.

Understanding the Trade-offs and Modern Features

When evaluating a muffle furnace, its modern features and the controller's capability are often the deciding factors.

The Importance of the Controller

The precision of your work is directly tied to the quality of the controller. A furnace with a simple digital controller is adequate for basic tasks like ashing, but it cannot perform complex thermal profiles required for materials science or advanced ceramics. The controller often represents a significant part of the furnace's cost and utility.

Essential Safety Systems

Modern furnaces are built with robust safety protocols. Key features to look for include over-current and over-voltage protection, which safeguard the electrical components.

Leakage protection is critical for operator safety, while rapid temperature rise protection can prevent damage to the furnace and the samples inside in case of a control system failure.

Construction and Durability

Many contemporary designs utilize a double-shell structure. This creates an air-cooling layer between the inner chamber and the outer cabinet, keeping the exterior safe to touch and improving temperature stability.

Making the Right Choice for Your Application

Selecting a muffle furnace requires matching its features to your specific goal, as over- or under-specifying can be a costly mistake.

- If your primary focus is basic material analysis (e.g., ashing, drying): A simple furnace with reliable time and temperature controls is sufficient and cost-effective.

- If your primary focus is advanced research or process development: You need a model with a multi-segment programmable controller to execute complex thermal cycles and ensure repeatability.

- If your primary focus is small-batch production: Prioritize robust construction, documented temperature uniformity, and integrated safety systems for reliable and safe day-to-day operation.

Understanding these core features allows you to select a tool that delivers the precise, clean, and repeatable heating your work demands.

Summary Table:

| Key Feature | Description | Primary Benefit |

|---|---|---|

| Isolated Heating Chamber | Sealed inner muffle separates samples from heat source | Prevents contamination, ensures clean processing |

| Uniform High Temperatures | Radiant and convection heating for consistent thermal treatment | Reliable results for annealing, sintering, ashing |

| Precise Control System | Programmable controllers for complex thermal cycles | Repeatable experiments and process automation |

| Rapid Thermal Cycling | Powerful heating elements for fast heating/cooling | Increased lab efficiency and throughput |

| Advanced Safety Systems | Over-temperature, over-current, and leakage protection | Safe operation for both users and equipment |

Ready to enhance your lab's capabilities with a precision muffle furnace?

At KINTEK, we specialize in providing laboratory equipment that delivers the clean, controlled, and uniform high-temperature environment your research or production requires. Whether you need basic ashing or advanced thermal cycling, our muffle furnaces are engineered for precision, safety, and durability.

Let us help you select the perfect furnace for your application:

- Basic Material Analysis: Cost-effective models with reliable temperature control

- Advanced Research: Programmable controllers for complex thermal profiles

- Small-Batch Production: Robust systems with documented temperature uniformity

Contact our experts today to discuss your specific needs and discover how KINTEK's solutions can bring precision and reliability to your high-temperature processes!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the safety precautions for using a muffle furnace? Essential Tips for Safe Operation

- Is a muffle furnace used for ash determination? Discover Its Critical Role in Accurate Analysis

- Does metal expand on heating or cooling? The Science of Thermal Expansion Explained

- When we heat a metal ring it gets expand or compressed? The Hole Gets Bigger, Not Smaller

- What are the classification of refractory materials? A Guide to Chemical and Thermal Selection