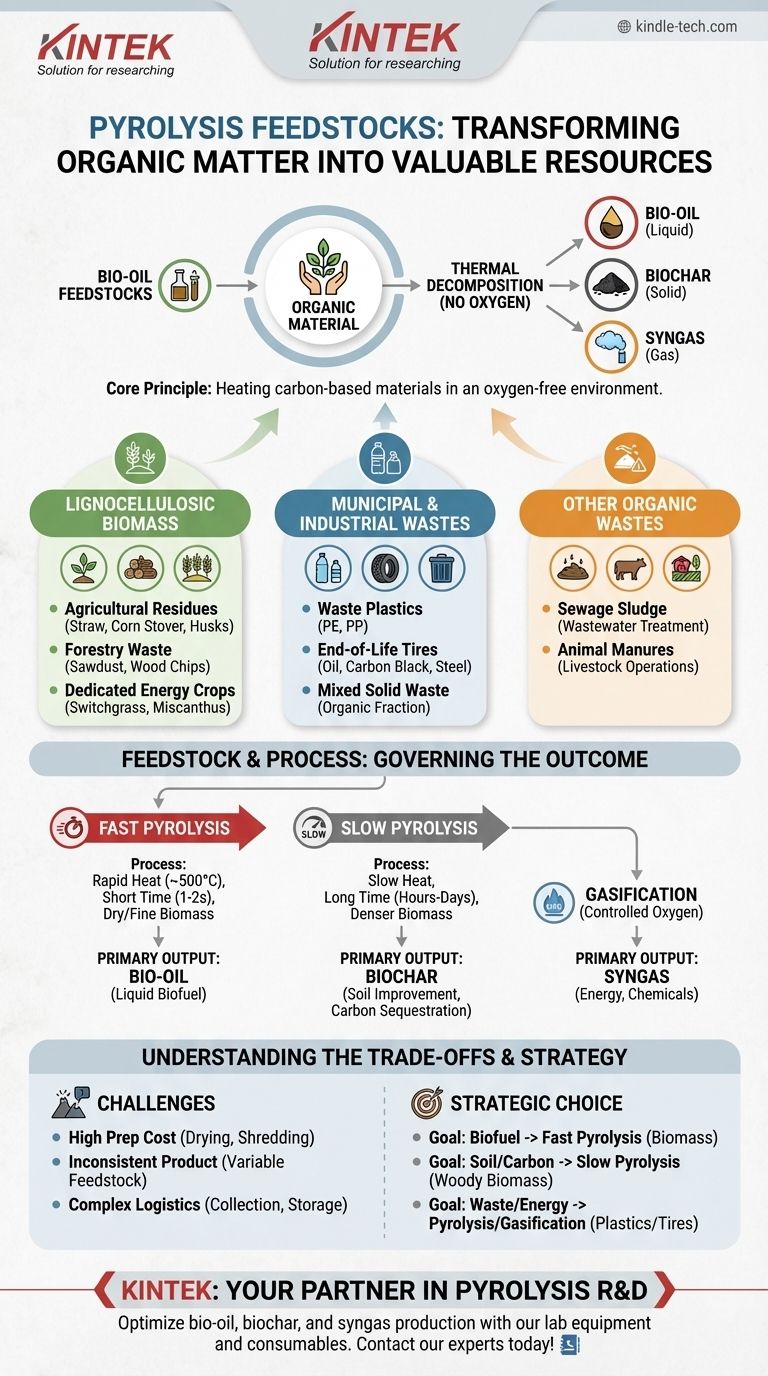

In essence, any organic material can be a feedstock for pyrolysis. This thermal decomposition process works by heating carbon-based materials in an oxygen-free environment. The most common feedstocks are lignocellulosic biomass, such as forest and agricultural residues, waste wood, and dedicated energy crops, which are broken down into valuable outputs like bio-oil, biochar, and syngas.

The critical insight is not just what can be used for pyrolysis, but why. Your choice of feedstock, combined with the process conditions you select, directly dictates the primary product you will generate—whether it's energy-rich oil, stable carbon char, or combustible gas.

What Defines a Pyrolysis Feedstock?

Pyrolysis is a flexible technology, but its efficiency and outputs are highly dependent on the raw material you put in. Understanding the core properties of a feedstock is the first step toward a successful process.

The Fundamental Requirement: Organic Matter

At its heart, pyrolysis is a method for breaking down complex organic molecules. This means the primary requirement for any feedstock is that it must be carbon-based. Inorganic materials like metals, glass, and rock will not pyrolyze.

Key Material Characteristics

The two most important characteristics of a feedstock are its composition and moisture content. Materials rich in lignocellulose (the structural components of plants, like cellulose, hemicellulose, and lignin) are ideal. Lower moisture content is always better, as evaporating water consumes a significant amount of energy, reducing the overall efficiency of the process.

The Impact of Contaminants

Contaminants can compromise the process and the quality of the final products. For example, high levels of chlorine (found in PVC plastics) can create corrosive acids, while heavy metals in the feedstock can concentrate in the biochar, limiting its use in agriculture.

Major Categories of Pyrolysis Feedstock

While the list of potential feedstocks is vast, they generally fall into a few primary categories, each with unique characteristics and potential uses.

Lignocellulosic Biomass

This is the most common and widely studied category. It includes any material derived from plants.

- Agricultural Residues: Straw, corn stover, rice husks, and sugarcane bagasse.

- Forestry Waste: Sawdust, wood chips, bark, and branches from logging operations.

- Dedicated Energy Crops: Fast-growing plants like switchgrass or miscanthus, cultivated specifically for energy conversion.

Municipal and Industrial Wastes

Pyrolysis offers a powerful solution for diverting waste from landfills and converting it into valuable products.

- Waste Plastics: Non-chlorinated plastics like polyethylene (PE) and polypropylene (PP) are excellent for producing high-quality pyrolysis oil.

- End-of-Life Tires: A challenging waste stream that pyrolysis can convert into oil, carbon black (a valuable industrial filler), and steel.

- Mixed Solid Waste (MSW): The organic fraction of household trash can be pyrolyzed, though it requires significant pre-sorting to remove inorganics.

Other Organic Wastes

Virtually any concentrated organic stream can be considered.

- Sewage Sludge: The solid, organic-rich material left over from wastewater treatment.

- Animal Manures: Agricultural wastes from livestock operations.

How Feedstock Choice Governs the Outcome

You cannot separate the feedstock from the process and its products. The type of material you start with strongly influences which process you should use and what you will primarily produce.

The Three Key Products

Pyrolysis breaks down organic matter into three main outputs: a liquid (bio-oil), a solid (biochar), and a non-condensable gas (syngas). The ratio of these products is determined by the process conditions.

Fast Pyrolysis for Bio-oil

To maximize the yield of liquid bio-oil, you need fast pyrolysis. This involves rapidly heating finely ground, dry biomass (like sawdust or straw) to a moderate temperature (~500°C) for a very short time (1-2 seconds). This "shocks" the material, favoring the production of vapors that are then rapidly cooled and condensed into oil.

Slow Pyrolysis for Biochar

To maximize the solid biochar, you use slow pyrolysis. This process involves heating the feedstock (often denser, woody material) at a much slower rate to a similar temperature but for a much longer residency time (hours to days). This allows the carbon to rearrange into a stable, solid structure.

Gasification for Syngas

Gasification is a related process that introduces a small, controlled amount of oxygen. This favors the conversion of the feedstock into syngas, a mixture of hydrogen, carbon monoxide, and methane, which can be used to generate electricity or produce chemicals.

Understanding the Trade-offs

While powerful, pyrolysis is not a magic bullet. There are practical and economic challenges to consider, many of which are tied directly to the feedstock.

The High Cost of Preparation

Most raw feedstocks are not ready for a reactor. They often need to be dried, shredded, or pelletized. This pre-treatment step requires energy and capital equipment, adding significant cost to the overall operation.

Inconsistent Feedstock, Inconsistent Product

Using a variable feedstock, like mixed municipal waste, will result in a variable output. The quality and composition of the bio-oil or biochar can fluctuate day to day, making it difficult to sell to customers who require a consistent product specification.

Feedstock Logistics are Complex

Collecting, transporting, and storing large volumes of low-density biomass can be a major logistical and economic hurdle. A pyrolysis facility's viability often depends on its proximity to a cheap and reliable feedstock source.

Making the Right Choice for Your Goal

The optimal feedstock is the one that best aligns with your available resources and your target product.

- If your primary focus is liquid biofuel production: Use dry, uniform biomass like wood pellets or agricultural residues in a fast pyrolysis process.

- If your primary focus is soil improvement or carbon sequestration: Use woody biomass in a slow pyrolysis process to maximize the yield of stable biochar.

- If your primary focus is waste management and energy generation: Use high-calorific wastes like plastics or tires, selecting a process optimized for either oil (pyrolysis) or gas (gasification).

Ultimately, successful pyrolysis depends on a clear strategy that aligns your specific feedstock with your desired end product and process capabilities.

Summary Table:

| Feedstock Category | Examples | Primary Pyrolysis Products |

|---|---|---|

| Lignocellulosic Biomass | Wood chips, straw, energy crops | Bio-oil, Biochar, Syngas |

| Municipal/Industrial Waste | Plastics (PE, PP), tires, MSW | Pyrolysis Oil, Carbon Black |

| Other Organic Wastes | Sewage sludge, animal manure | Biochar, Syngas |

Ready to transform your organic materials into valuable products? KINTEK specializes in lab equipment and consumables for pyrolysis research and development. Whether you're processing biomass, plastics, or other feedstocks, our solutions help you optimize bio-oil, biochar, and syngas production. Contact our experts today to discuss your specific feedstock and pyrolysis goals!

Visual Guide

Related Products

- Conductive Carbon Cloth Carbon Paper Carbon Felt for Electrodes and Batteries

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

- Custom PTFE Teflon Parts Manufacturer for Culture Dish and Evaporation Dish

- Spark Plasma Sintering Furnace SPS Furnace

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

People Also Ask

- What are the material properties of carbon paper? Unlocking High Conductivity & Porosity for Your Lab

- What are the four main types of sensors? A Guide to Power Source and Signal Type

- What are the common applications for carbon cloth? Unlock Its Potential in Energy & Electrochemical Systems

- What can carbon nanotubes be used for? Unlock Superior Performance in Batteries & Materials

- What are 3 products that carbon nanotubes can be used in? Enhancing Batteries, Tires, and Composites