At its core, the five fundamental heat treatment processes for metals are annealing, normalizing, hardening, tempering, and case hardening. Each process involves a carefully controlled cycle of heating and cooling to deliberately alter a metal's internal crystalline structure. This manipulation allows you to precisely engineer its mechanical properties—such as hardness, toughness, and ductility—to meet the demands of a specific application.

Heat treatment is not a single action but a toolkit for controlling a metal's microstructure. The fundamental goal is to manage the critical trade-off between hardness (resistance to wear and deformation) and toughness (resistance to fracture).

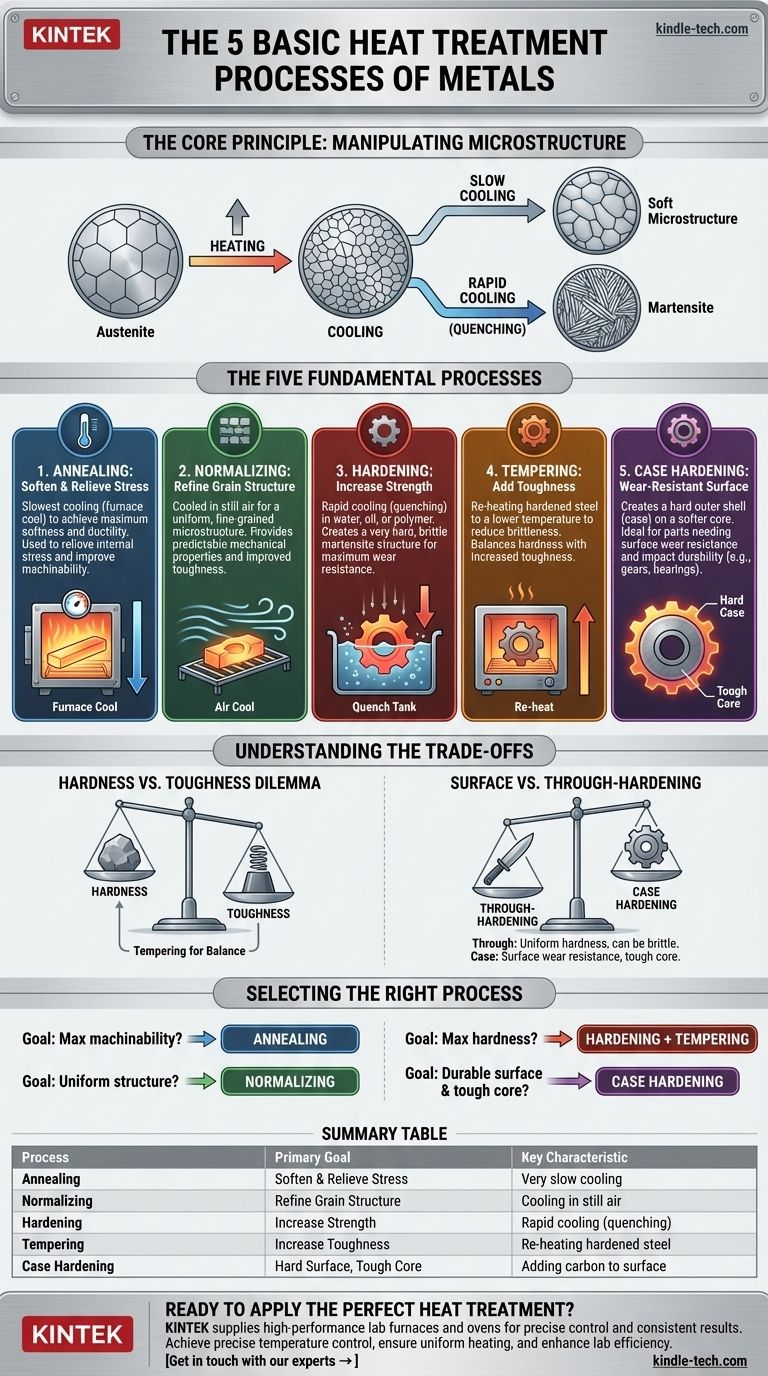

The Core Principle: Manipulating Microstructure

All heat treatment processes work by changing the metal's internal grain structure, known as its microstructure. By heating steel, for example, you change its crystal structure to a form called austenite, which can dissolve carbon.

How you cool it from this state determines the final microstructure and, therefore, its properties. Slow cooling allows for soft, ductile structures, while rapid cooling (quenching) traps the structure in a very hard, brittle state called martensite.

The Five Fundamental Processes

Each basic process uses a unique heating and cooling profile to achieve a specific outcome.

1. Annealing: To Soften and Relieve Stress

Annealing is a process used to make a metal as soft and ductile as possible. This is often done to relieve internal stresses from prior work (like cold forming), improve machinability, or prepare it for further shaping.

The process involves heating the metal to a specific temperature, "soaking" it at that temperature for a set time, and then cooling it very slowly, often by leaving it in the turned-off furnace. This slow cooling allows the microstructure to form into its softest, most stable state.

2. Normalizing: To Refine Grain Structure

Normalizing is similar to annealing but with a key difference in the cooling rate. Its primary goal is to create a more uniform and fine-grained microstructure, which provides more predictable mechanical properties and improved toughness compared to an annealed part.

After heating and soaking, the metal is removed from the furnace and cooled in still air. This faster cooling rate (compared to furnace cooling) results in a slightly harder and stronger material than a fully annealed one, but with less internal stress than an untreated part.

3. Hardening: To Increase Strength

Hardening is used to increase the strength and wear resistance of a metal. For steels, this is done to achieve maximum hardness.

The process involves heating the steel to form austenite, followed by a rapid cooling process called quenching. The metal is typically plunged into water, oil, or a polymer solution. This "freezes" the microstructure into the hard, brittle martensite form.

4. Tempering: To Add Toughness

A part that has been hardened is often too brittle for most practical applications; it has high strength but very low resistance to impact. Tempering is a secondary process performed immediately after hardening to reduce this brittleness and increase toughness.

The hardened part is re-heated to a much lower temperature (below the hardening temperature) and held for a specific time. This process relieves some of the internal stress and allows the brittle martensite to transform into a more durable microstructure, balancing hardness with toughness.

5. Case Hardening: For a Wear-Resistant Surface

Case hardening (or surface hardening) creates a part with two distinct zones: a very hard, wear-resistant outer shell (the "case") and a softer, tougher inner core. This is ideal for components like gears or bearings that need to resist surface wear while also withstanding impact loading.

There are many methods, but a common one is carburizing, where a low-carbon steel part is heated in a carbon-rich atmosphere. Carbon diffuses into the surface, which is then quenched and tempered. The result is a high-carbon (hard) surface and a low-carbon (tough) core.

Understanding the Inherent Trade-offs

Choosing a heat treatment process is always an exercise in balancing competing properties. No single process is universally "best."

The Hardness vs. Toughness Dilemma

This is the most critical trade-off in metallurgy. As you increase a metal's hardness (its ability to resist scratching and indentation), you almost always decrease its toughness (its ability to absorb energy and resist fracture).

A fully hardened, untempered steel file is extremely hard but will shatter if dropped. A fully annealed piece of steel is very tough and ductile but too soft to hold an edge. Tempering is the process specifically designed to find the optimal balance between these two properties for a given application.

Surface vs. Through-Hardening

Deciding between case hardening and through-hardening (hardening the entire part) depends entirely on the component's function.

Through-hardening is suitable for tools like blades or dies that require uniform hardness. However, it can make large components more prone to brittle failure. Case hardening is superior for parts that experience both surface wear and shock loads, like a camshaft, preserving a ductile core that can absorb impact.

Selecting the Right Process for Your Goal

Your choice of heat treatment should be driven by the final performance requirements of the component.

- If your primary focus is maximum machinability and formability: Use annealing to make the metal as soft and stress-free as possible before subsequent operations.

- If your primary focus is a uniform and predictable structure: Use normalizing to refine the grain size and ensure consistent properties before a final hardening process.

- If your primary focus is maximum hardness and wear resistance: Use hardening followed by tempering to achieve high strength while tuning the final toughness to prevent brittleness.

- If your primary focus is a durable surface with a tough, impact-resistant core: Use case hardening to create a dual-property component optimized for its environment.

By understanding these fundamental processes, you can transform a standard metal into a high-performance material engineered for a specific task.

Summary Table:

| Process | Primary Goal | Key Characteristic |

|---|---|---|

| Annealing | Soften & Relieve Stress | Very slow cooling (furnace cool) |

| Normalizing | Refine Grain Structure | Cooling in still air |

| Hardening | Increase Strength & Hardness | Rapid cooling (quenching) |

| Tempering | Increase Toughness | Re-heating hardened steel |

| Case Hardening | Hard Surface, Tough Core | Adding carbon to surface (e.g., carburizing) |

Ready to apply the perfect heat treatment to your materials?

The precise control required for processes like annealing, hardening, and tempering depends on reliable, high-performance lab equipment. KINTEK specializes in supplying the furnaces, ovens, and consumables your laboratory needs to achieve consistent, repeatable results.

We help you:

- Achieve precise temperature control for accurate annealing and hardening cycles.

- Ensure uniform heating critical for normalizing and case hardening.

- Enhance your lab's efficiency and safety with durable, dependable equipment.

Contact us today to discuss how our solutions can support your specific metal heat treatment applications and improve your material outcomes.

Get in touch with our experts →

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What are the mechanical properties of graphite? Harnessing Rigidity and Managing Brittleness

- What advantages does a vacuum drying oven offer over a conventional drying oven? Enhance SCWO Research Accuracy

- Why is a constant temperature shaker utilized in Methylene Blue adsorption experiments? Ensure Precise Data Integrity

- How do ULT freezers maintain a uniform temperature? Achieve Stable Sample Storage with Advanced Cooling

- What is the use of pyrolysis fuel? A Sustainable Substitute for Industrial Heating and Power

- Why is it important to match the freezer temperature to storage recommendations? Optimize Food Safety & Energy Use

- What are the most common types of heat treatment? Master Annealing, Hardening, Tempering & More

- Why is precision mixing required for concrete corrosion studies? Ensure Data Integrity through Homogenization