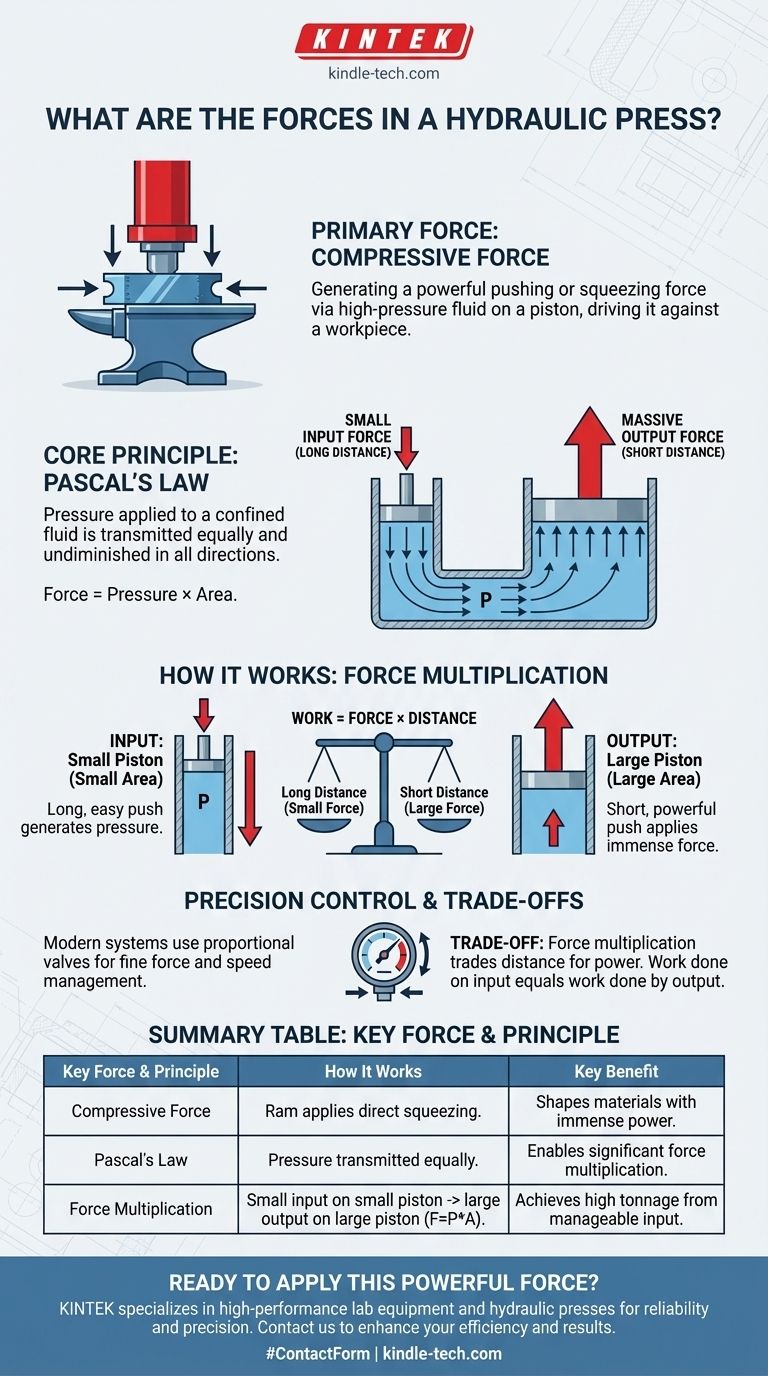

The primary force in a hydraulic press is compressive force. This is a pushing or squeezing force generated when high-pressure hydraulic fluid acts upon a piston, driving it against a workpiece. This entire operation is governed by a fundamental principle of fluid mechanics.

The core concept is force multiplication. A hydraulic press doesn't create energy, but it masterfully trades a small input force applied over a long distance for a massive output force applied over a short distance, all thanks to the properties of an enclosed fluid.

The Core Principle: Pascal's Law

The ability of a hydraulic press to generate immense force comes from a simple yet powerful principle of fluid dynamics discovered by Blaise Pascal.

What is Pascal's Law?

Pascal's Law states that when pressure is applied to a fluid in a confined space, that pressure is transmitted equally and undiminished in all directions throughout the fluid.

In a hydraulic system, the fluid (usually oil) is incompressible. This means when you push on it, it doesn't squeeze down; it transmits that push perfectly.

The Two-Piston System

A hydraulic press consists of two connected, sealed cylinders of different sizes, each with its own piston. A small force is applied to the smaller input piston.

Because the fluid is enclosed, the pressure created by this small input force is transmitted throughout the fluid, pushing on the much larger output piston (also known as the ram).

How Pressure Creates Immense Force

The relationship is defined by the formula: Force = Pressure x Area.

Since the pressure is the same everywhere in the fluid, the force exerted on each piston is directly proportional to its surface area. A piston with 10 times the area will produce 10 times the force. This is how a small manual pump can generate the tonnage needed to forge steel.

The Primary Force at Work: Compression

While Pascal's Law explains how the force is generated, the force itself is used to compress and shape materials.

Defining Compressive Force

A compressive force is a force that pushes or squeezes an object, attempting to reduce its volume or change its shape.

In the press, the output piston or ram moves downward, applying this direct squeezing force onto a billet, ingot, or other workpiece that is resting on a stationary plate or anvil.

Fine Control Over Force

Modern hydraulic presses use proportional control valves and pumps. This allows operators to precisely manage the speed and amount of compressive force, enabling the creation of complex and unique shapes with high accuracy.

Understanding the Trade-offs

The massive force multiplication of a hydraulic press does not come for free. It involves a critical trade-off that is governed by the laws of physics.

The Cost of Force Multiplication: Distance

The work done on the input piston must equal the work done by the output piston (ignoring minor friction losses). Since Work = Force x Distance, a balance must be maintained.

To move the large output piston a small distance, the small input piston must be moved a much greater distance. You are trading a long, easy push for a short, powerful one.

System Pressure vs. Piston Size

The maximum force of a press is determined by two factors: the maximum pressure the hydraulic system can generate and the surface area of the output piston. Increasing either of these will increase the potential compressive force.

Making the Right Choice for Your Application

Understanding these forces helps you see why hydraulic presses are chosen for specific tasks.

- If your primary focus is immense power: The key is the ratio of the piston areas; a larger output piston relative to the input piston results in greater force multiplication for tasks like forging and stamping.

- If your primary focus is precision control: The hydraulic valves and pump controls are what matter, as they allow for the exact application of force and speed needed for complex molding or assembly tasks.

Ultimately, the elegant application of fluid pressure is what allows a hydraulic press to convert a manageable input into an overwhelming compressive force.

Summary Table:

| Key Force & Principle | How It Works | Key Benefit |

|---|---|---|

| Compressive Force | The ram applies a direct squeezing force to the workpiece. | Shapes and forms materials with immense power. |

| Pascal's Law | Pressure applied to an incompressible fluid is transmitted equally throughout the system. | Enables significant force multiplication. |

| Force Multiplication | A small input force on a small piston creates a large output force on a large piston (Force = Pressure × Area). | Achieves high tonnage from a manageable input. |

Ready to apply this powerful force to your lab or production needs?

KINTEK specializes in high-performance lab equipment, including hydraulic presses designed for reliability and precision. Whether your application requires immense forging power or delicate molding control, our solutions are engineered to meet your exact specifications.

Contact us today using the form below to discuss how a KINTEK hydraulic press can enhance your efficiency and results.

Visual Guide

Related Products

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual Lab Heat Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- What is the function of a laboratory hydraulic press for Li10GeP2S12 pellets? Optimize Solid-State Battery Performance

- What is KBr disc method? A Complete Guide to IR Spectroscopy Sample Prep

- How does a laboratory manual hydraulic press facilitate the FT-IR characterization of catalysts? Master Sample Prep.

- Why is a hydraulic pellet press used for FTIR? Transform Nanofillers into Clear Data

- Why is a laboratory hydraulic press utilized for electrolyte pelletizing? Unlock High Ionic Conductivity