At its core, spark plasma sintering (SPS) is an advanced consolidation technique that uses a pulsed direct electrical current and uniaxial pressure to transform powders into a dense solid. Unlike conventional methods that heat materials from the outside in, SPS passes current directly through the powder and its tooling, generating rapid, uniform heat internally through a combination of plasma and Joule heating effects.

The fundamental advantage of SPS is not just speed, but control. By rapidly heating materials at lower overall temperatures, it preserves the fine-grained microstructures essential for creating high-performance, next-generation materials that are impossible to produce with slower, conventional methods.

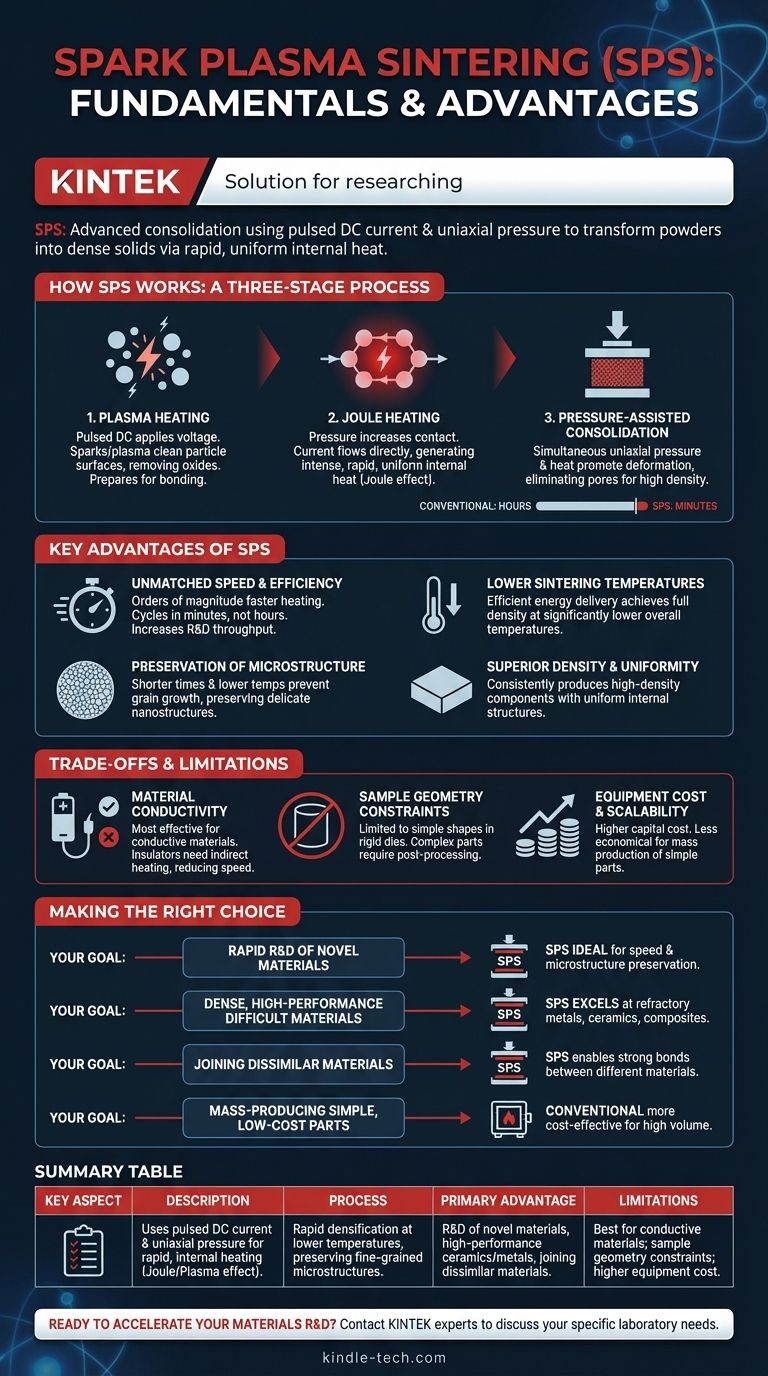

How Spark Plasma Sintering Works: A Three-Stage Process

The SPS process is remarkably fast, often completing in minutes what would take a conventional furnace hours. This efficiency is achieved through a unique sequence of physical phenomena.

Stage 1: Plasma Heating

Initially, the powder particles are only loosely touching. When the pulsed DC voltage is applied, it can create sparks or a plasma discharge in the microscopic gaps between particles.

This initial plasma state is crucial for cleaning the surfaces of the powder particles by removing absorbed gases and oxide layers, which prepares them for superior bonding.

Stage 2: Joule Heating

As pressure is applied and the particles begin to make better contact, the electrical current flows directly through the conductive path they create.

This generates intense, rapid, and uniform heat throughout the material via the Joule effect—the same principle that heats the element in an electric stove. This internal heating is the dominant mechanism responsible for the process's incredible speed.

Stage 3: Pressure-Assisted Consolidation

Simultaneously with the heating, a strong uniaxial pressure is applied. This force complements the high temperature by promoting plastic deformation of the powder particles.

The combination of heat and pressure rapidly eliminates the pores between particles, forcing them to fuse together and form a low-porosity, highly dense final component.

The Key Advantages of the SPS Method

The unique mechanism of SPS provides several distinct advantages over traditional furnace-based sintering, making it a critical tool for advanced materials science.

Unmatched Speed and Efficiency

The direct, internal heating allows for heating rates that are orders of magnitude faster than conventional furnaces. Sintering cycles are reduced from many hours to just a few minutes, drastically increasing research and development throughput.

Lower Sintering Temperatures

Because the energy is delivered so efficiently, the required overall temperature to achieve full density is often several hundred degrees lower than in conventional processes.

Preservation of Microstructure

The combination of lower temperatures and shorter times is the most significant benefit of SPS. It prevents the unwanted growth of microscopic grains within the material, allowing scientists to preserve delicate or nanometer-scale structures that give a material its unique properties.

Superior Density and Uniformity

The process consistently produces components with very high density and a uniform internal structure, which is critical for achieving predictable mechanical and physical performance.

Understanding the Trade-offs and Limitations

While powerful, SPS is not a universal solution. An objective assessment requires understanding its practical constraints.

The Role of Material Conductivity

The primary mechanism of SPS relies on electrical current passing through the powder. The process is most effective for conductive or semi-conductive materials like metals and many ceramics.

While insulating powders can be sintered, they require a conductive die (typically graphite) to heat them indirectly, which can diminish some of the speed and uniformity advantages.

Constraints on Sample Geometry

SPS is typically performed in simple, rigid dies, most often cylindrical. This limits the "as-sintered" shape of the final part. Complex geometries require significant post-processing and machining.

Equipment Cost and Scalability

SPS systems are highly specialized and carry a higher capital cost than most conventional furnaces. This can make them less economical for the mass production of simple, inexpensive components where traditional methods suffice.

Making the Right Choice for Your Goal

Selecting the right sintering method depends entirely on your material, performance requirements, and production goals.

- If your primary focus is rapid R&D of novel materials: SPS is the ideal choice due to its speed and unmatched ability to preserve the nanostructures and unique phases you are engineering.

- If your primary focus is creating dense, high-performance components from difficult-to-sinter materials: SPS excels at consolidating refractory metals, advanced ceramics, and composites that fail to densify properly with conventional methods.

- If your primary focus is joining dissimilar materials (e.g., metal-to-ceramic): SPS offers unique capabilities for creating strong, reliable bonds between materials that are otherwise difficult or impossible to weld together.

- If your primary focus is mass-producing simple, low-cost parts: Conventional press-and-sinter furnace operations are likely the more cost-effective solution for high-volume, less demanding applications.

Ultimately, spark plasma sintering is a transformative tool that empowers the creation of advanced materials by providing precise control over density and microstructure at speeds conventional methods cannot match.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process | Uses pulsed DC current and uniaxial pressure for rapid, internal heating (Joule/Plasma effect). |

| Primary Advantage | Rapid densification at lower temperatures, preserving fine-grained microstructures. |

| Ideal For | R&D of novel materials, high-performance ceramics/metals, joining dissimilar materials. |

| Limitations | Best for conductive materials; sample geometry constraints; higher equipment cost. |

Ready to accelerate your materials R&D with precise control over density and microstructure?

KINTEK specializes in advanced lab equipment, including solutions for sintering and materials consolidation. Our expertise can help you leverage technologies like spark plasma sintering to develop next-generation materials faster and more efficiently.

Contact our experts today to discuss how we can support your laboratory's specific needs and goals.

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Graphite Vacuum Continuous Graphitization Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Can aluminum be sintered? Overcome the Oxide Barrier for Complex, Lightweight Parts

- What are the different sintering methods? Choose the Right Technique for Your Material & Application

- What is the vapor phase material? Unlock Faster, Denser Sintering with SPS Technology

- What is the mechanism of SPS process? A Deep Dive into Rapid, Low-Temperature Sintering

- What is the plasma sintering technique? Achieve Rapid, High-Density Material Fabrication