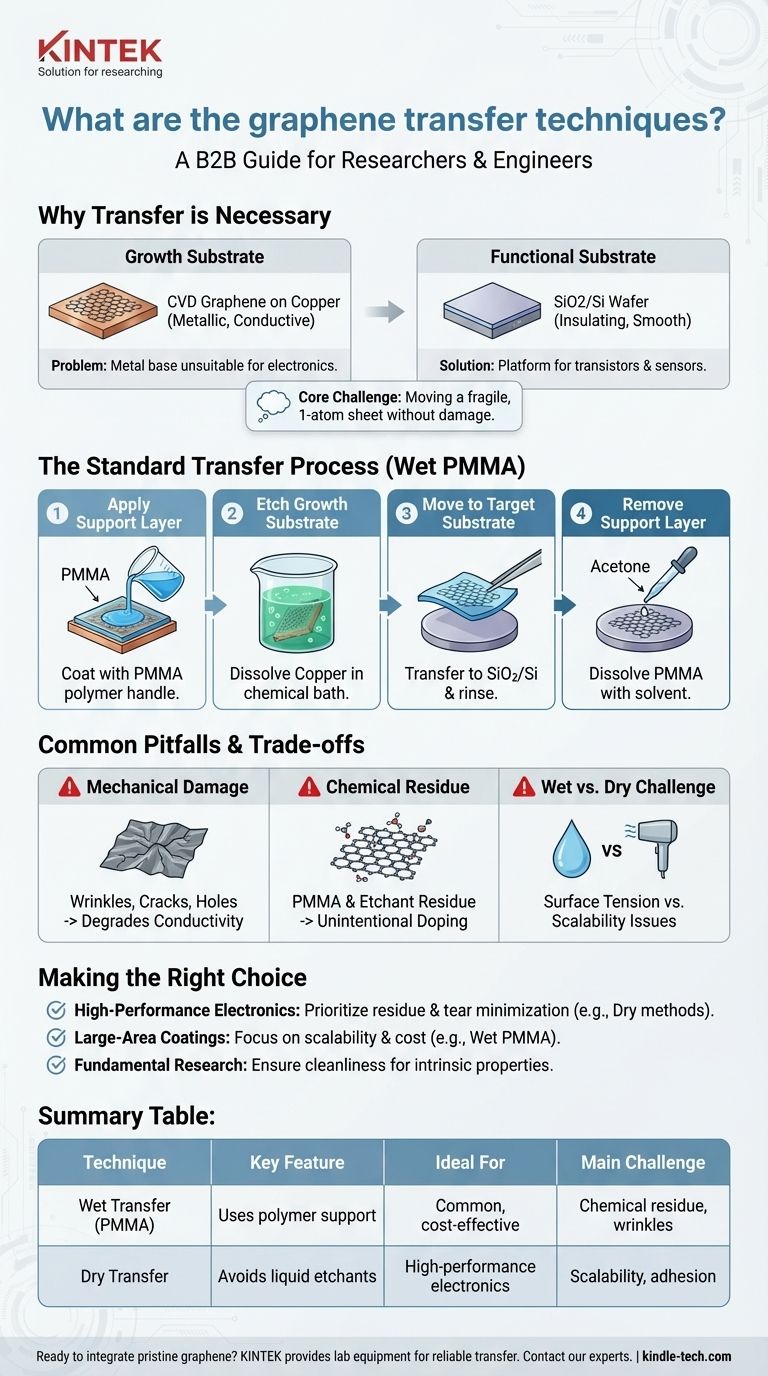

The most common method for transferring graphene involves using a polymer support layer, typically PMMA, to move the single-atom-thick film from its growth substrate to a target substrate. After coating the graphene with PMMA, the original growth substrate is chemically etched away, leaving a floating PMMA/graphene film that can be carefully placed onto a new surface before the PMMA is dissolved.

The core challenge of graphene transfer is moving a fragile, one-atom-thick sheet from one surface to another without introducing wrinkles, tears, or chemical contamination that would degrade its exceptional properties.

Why Graphene Transfer is Necessary

The Problem of the Growth Substrate

Graphene is often synthesized using methods like Chemical Vapor Deposition (CVD), where it grows as a thin film on a metallic catalyst, such as copper foil.

While excellent for growth, these metallic substrates are not suitable for the final applications of graphene, particularly in electronics where an insulating or semiconducting base is required.

Moving to a Functional Substrate

To build transistors, sensors, or other devices, the graphene must be moved to a functional target substrate.

A silicon wafer with an oxide layer (SiO2/Si) is a common choice because it is insulating, has a very smooth surface, and is the standard platform for the entire semiconductor industry. The transfer process is the critical bridge between graphene synthesis and its practical application.

The Anatomy of a Standard Transfer Process

The most established technique is a "wet transfer" that uses a polymer scaffold to support the graphene film.

Step 1: Applying the Support Layer

A polymer solution, most commonly poly(methyl methacrylate) or PMMA, is coated directly on top of the graphene film as it sits on its original growth substrate.

This PMMA layer acts as a temporary handle and mechanical support, preventing the ultrathin graphene from folding, tearing, or disintegrating during subsequent steps.

Step 2: Etching the Growth Substrate

The entire sample (PMMA/graphene/copper) is placed in a chemical bath, or etchant, that selectively dissolves the original growth substrate.

For a copper substrate, an etchant like ferric chloride or ammonium persulfate is used. This process leaves the PMMA/graphene film floating on the surface of the liquid.

Step 3: Moving to the Target Substrate

The floating film is carefully "fished" out of the etchant solution, often by submerging the target SiO2/Si substrate beneath it and slowly lifting it out.

The film is then rinsed in deionized water to remove residual etchant before being carefully draped over the new substrate.

Step 4: Removing the Support Layer

Once the film is securely positioned on the target substrate, the final step is to remove the PMMA support layer.

This is typically done by dissolving the PMMA with a solvent like acetone, followed by a final rinse. If successful, only a clean, single layer of graphene remains on the new substrate.

Common Pitfalls and Trade-offs

A perfect transfer is the ideal, but the reality involves significant challenges that can impact the quality of the final graphene film.

The Problem of Mechanical Damage

Handling an atom-thick sheet is incredibly difficult. Wrinkles, cracks, and holes are common defects introduced during the transfer.

These imperfections disrupt the continuous honeycomb lattice of the graphene, degrading its electrical conductivity and mechanical strength.

The Issue of Chemical Residue

The chemicals used in the process—namely the PMMA and the etchants—can leave behind residue and contamination.

Even trace amounts of polymer or metallic ions can unintentionally "dope" the graphene, altering its electronic properties and hindering device performance.

The Wet vs. Dry Challenge

The standard "wet" transfer process described introduces surface tension from liquids, which can cause wrinkling and require careful drying.

This has led to the development of alternative "dry" transfer methods, though they often have their own trade-offs regarding scalability and film adhesion. The wet PMMA method remains the most common due to its relative simplicity and low cost.

Making the Right Choice for Your Goal

The acceptable level of defects in a transfer process depends entirely on the intended application.

- If your primary focus is high-performance electronics: The priority must be a transfer process that minimizes chemical residue and mechanical tears, as these directly impact carrier mobility and device reliability.

- If your primary focus is large-area coatings or composites: Scalability, cost, and maintaining film continuity over large areas are more critical than achieving a perfectly pristine, defect-free monolayer.

- If your primary focus is fundamental research: The cleanliness of the transfer and the choice of substrate are paramount to ensure that experimental measurements reflect the intrinsic properties of graphene, not artifacts from the process.

Ultimately, mastering the transfer of graphene is just as crucial as mastering its growth for unlocking its true potential.

Summary Table:

| Technique | Key Feature | Ideal For | Main Challenge |

|---|---|---|---|

| Wet Transfer (PMMA) | Uses polymer support layer | Common method, cost-effective | Chemical residue, wrinkles |

| Dry Transfer | Avoids liquid etchants | High-performance electronics | Scalability, adhesion |

Ready to integrate pristine graphene into your devices? The right transfer technique is critical for performance. KINTEK specializes in providing the lab equipment and consumables necessary for reliable graphene transfer, serving research and development laboratories. Contact our experts today to discuss how we can support your specific application needs and ensure high-quality results.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Cold Isostatic Pressing Machine CIP for Small Workpiece Production 400Mpa

- Custom PTFE Teflon Parts Manufacturer for PTFE Containers

- Graphite Vacuum Continuous Graphitization Furnace

People Also Ask

- What is the CVD diamond growth process? A Guide to Building Diamonds Atom by Atom

- What is sputtering method of thin film deposition? A Guide to Precision Coating

- What are the applications of Apcvd? High-Speed, Cost-Effective Thin-Film Deposition Solutions

- How do you transfer graphene? Master the PMMA Wet Transfer Process for Flawless Results

- What is the importance of chemical Vapour deposition? Unlock High-Purity, High-Performance Materials

- What are the applications of physical vapor deposition method? Unlock Superior Thin-Film Performance

- What is deposition in semiconductor? The Key to Building Modern Microchips

- What advantages do CVD furnaces offer for Wf/W composites? Preserving Fiber Ductility and Interface Integrity