The primary hazards of a hydraulic press are rooted in the immense force it generates and the high-pressure fluid system that powers it. These dangers can be broadly categorized into three areas: catastrophic mechanical failure, hazardous hydraulic fluid leaks, and critical operator error. Ignoring any of these can lead to severe injury or equipment damage.

A hydraulic press concentrates massive energy into a small space. The principal hazards are not just the obvious crushing force, but also the less visible risks of high-pressure fluid injection, component failure under load, and the fire potential of hydraulic fluids.

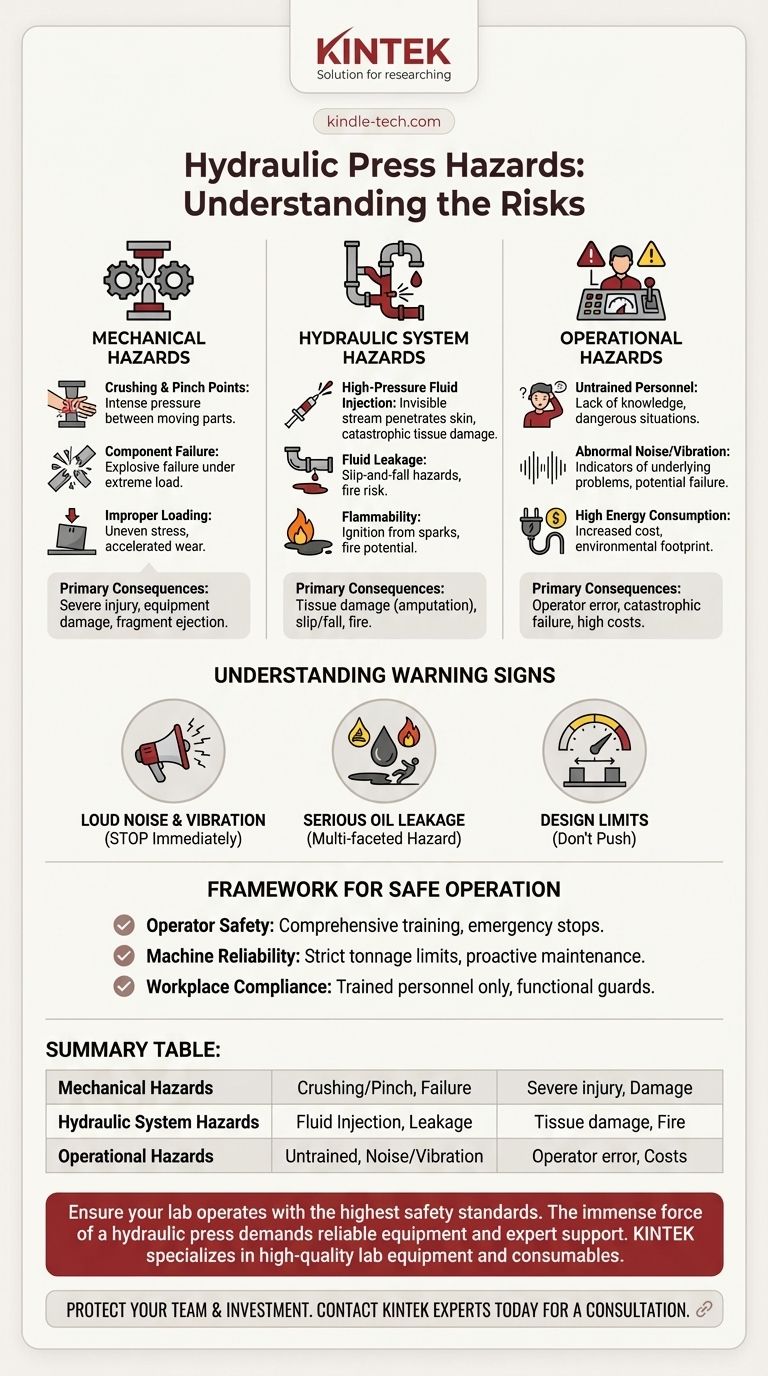

The Core Hazard Categories

To operate a hydraulic press safely, you must understand the distinct types of risk it presents. Each category requires a different focus for mitigation and prevention.

Mechanical Hazards

The most evident danger is the press's raw physical power. The moving ram and platen are designed to exert tons of force.

Crushing and Pinch Points are the most direct risk. Any body part caught between the die, the workpiece, and the press structure will be subjected to immense, unforgiving pressure.

Component Failure under extreme load is another critical risk. If the press frame or its components are stressed beyond their design limits, a sudden, explosive failure can occur, ejecting metal fragments at high velocity.

Improper Loading, such as exceeding the machine's maximum limit of eccentricity, places uneven stress on the press structure and slider. This can accelerate wear and lead to premature mechanical failure.

Hydraulic System Hazards

The hydraulic system itself presents a unique set of dangers separate from the mechanical action of the press.

High-Pressure Fluid Injection is one of the most severe and underestimated risks. A pinhole leak in a high-pressure line can eject a nearly invisible stream of hydraulic fluid powerful enough to penetrate skin and cause catastrophic tissue damage, often requiring amputation.

Fluid Leakage creates significant slip-and-fall hazards on the workshop floor. A seemingly minor leak can quickly become a major safety issue for the entire area.

Flammability is a key concern with some hydraulic fluids. If a leak occurs near an ignition source, such as sparks from grinding or welding, it can result in a serious fire.

Operational and Environmental Hazards

How the machine is operated and maintained is as critical as its mechanical design.

Untrained Personnel are a major liability. An operator who does not understand the machine's limits, safety features, or emergency procedures can easily create a dangerous situation.

Abnormal Noise or Vibration are not minor issues; they are clear indicators of an underlying problem. These symptoms often precede a major mechanical or hydraulic failure and must be addressed immediately.

High Energy Consumption, while not a direct physical hazard, contributes to a higher operational cost and environmental footprint. This is an important consideration in the overall management of the machine.

Understanding the Warning Signs

Trust in your machine should never become complacency. A hydraulic press will almost always provide clear signals that something is wrong before a catastrophic failure.

Recognizing Imminent Failure

If the machine begins making loud, unusual noises or exhibits abnormal vibration, it must be stopped immediately. These are classic signs of internal mechanical problems, hydraulic cavitation, or mounting issues that require immediate investigation by a qualified technician.

The Danger of a "Simple Leak"

Never dismiss serious oil leakage. As noted, a leak is a multi-faceted hazard, presenting risks of injection injury, fire, and falls. It also indicates a failing seal, hose, or fitting that could rupture completely under pressure.

Adhering to Design Limits

A hydraulic press has built-in overload protection to prevent catastrophic failure from excessive pressure. However, this is a safety system, not an operational tool. Consistently pushing the machine to its limits or operating it with an unbalanced load will cause cumulative damage and ultimately lead to failure.

A Framework for Safe Operation

Your approach to safety should be dictated by your primary responsibility and goals.

- If your primary focus is operator safety: Prioritize comprehensive training on standard operating procedures, emergency stops, and the immediate recognition of warning signs like leaks or unusual noises.

- If your primary focus is machine reliability: Enforce strict adherence to tonnage and eccentricity limits and implement a proactive maintenance schedule to address fluid integrity and component wear.

- If your primary focus is workplace compliance: Ensure that only trained and authorized personnel operate the machinery and that all safety guards and overload protections are inspected and fully functional.

By respecting the immense power of the hydraulic press and understanding its specific hazards, you can harness its capabilities safely and effectively.

Summary Table:

| Hazard Category | Key Risks | Primary Consequences |

|---|---|---|

| Mechanical Hazards | Crushing/Pinch Points, Component Failure, Improper Loading | Severe injury, equipment damage, ejection of fragments |

| Hydraulic System Hazards | High-Pressure Fluid Injection, Fluid Leakage, Flammability | Tissue damage (amputation), slip/fall hazards, fire |

| Operational Hazards | Untrained Personnel, Abnormal Noise/Vibration, High Energy Use | Operator error, potential for catastrophic failure, high costs |

Ensure your lab operates with the highest safety standards. The immense force of a hydraulic press demands reliable equipment and expert support. KINTEK specializes in high-quality lab equipment and consumables, serving laboratories that prioritize safety and precision. Our team can help you select the right press and implement safe operational protocols. Protect your team and your investment—contact our experts today for a consultation.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Heat Press Machine

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is the purpose of using a laboratory hydraulic press for cold pre-pressing? Optimize Your Composite Synthesis

- Why KBr is used as material for pellets formation in IR-spectroscopy? The Ideal Matrix for Clear, Accurate Analysis

- What is a pressed pellet? Achieve Accurate Sample Analysis with Proper Pellet Preparation

- How does a laboratory hydraulic press reduce interface impedance in solid-state batteries? Achieve Peak Ion Conductivity

- What is uniaxial pressing of ceramics? A Guide to High-Volume Production of Simple Shapes

- What is the process of XRF analysis? Master Sample Prep for Accurate Results

- Is KBr used in IR spectroscopy? The Essential Guide to Solid Sample Analysis

- What are the applications of mechanical press? High-Speed Stamping for Mass Production