At first glance, a laboratory oven seems like a simple heating device, but its operation involves significant hazards that are often overlooked. The primary dangers stem from extreme heat, the release of toxic fumes or vapors from heated materials, and the potential degradation of the oven's own insulation materials over time.

While the most obvious hazard is the risk of severe burns, the more insidious dangers come from inhaling toxic vapors released from samples or breathing in hazardous fibers from older insulation. Understanding what you are heating is the most critical aspect of safe oven operation.

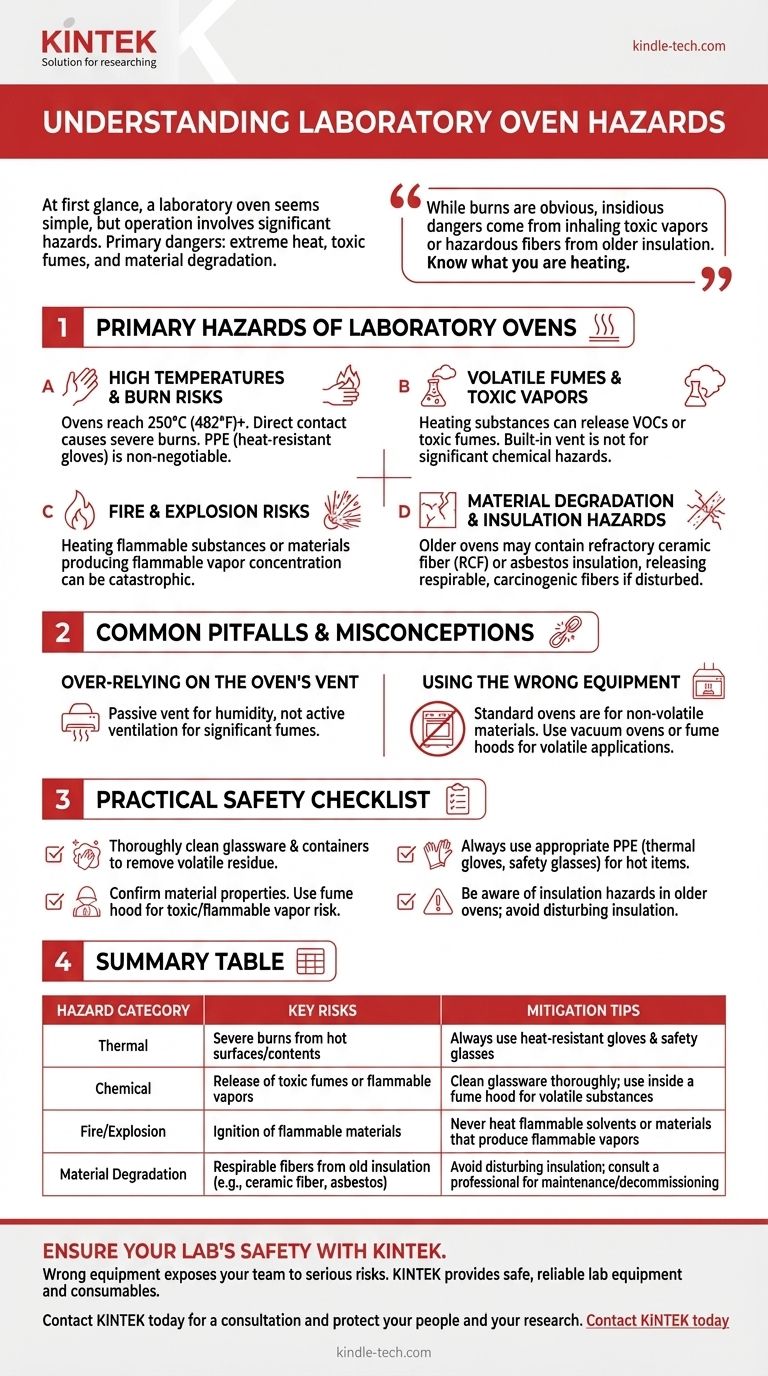

The Primary Hazards of Laboratory Ovens

A thorough understanding of each potential risk is the first step toward creating a safe working environment. These hazards can be broadly categorized into thermal, chemical, and material risks.

High Temperatures and Burn Risks

This is the most direct and easily understood hazard. Laboratory ovens operate at temperatures that can easily reach 250°C (482°F) or higher.

Direct contact with the oven's interior surfaces, racks, or heated contents can cause severe burns. Proper personal protective equipment (PPE), specifically heat-resistant gloves, is non-negotiable when handling items.

Volatile Fumes and Toxic Vapors

Heating substances can cause them to release volatile organic compounds (VOCs), toxic fumes, or other hazardous vapors into the air.

This is especially dangerous if containers are not thoroughly cleaned of solvents or if the material being dried contains toxic residue. The oven's built-in vent is only designed for humidity and minor fumes, not for containing significant chemical hazards.

Fire and Explosion Risks

Placing volatile or flammable substances inside an oven creates a severe risk of fire or explosion. The combination of heat, contained vapors, and an ignition source can have catastrophic results.

Never use a laboratory oven to dry flammable solvents or materials that can produce a flammable vapor concentration.

Material Degradation and Insulation Hazards

The construction of the oven itself can pose a risk, particularly in older or high-temperature models.

Some ovens contain refractory ceramic fiber insulation, which can degrade over time and release respirable fibers. These particles, which may contain crystalline silica, can cause chronic lung injury (silicosis).

Furthermore, very old equipment may even contain asbestos insulation. Disturbing this material during maintenance or decommissioning can release carcinogenic fibers and requires professional handling.

Common Pitfalls and Misconceptions

Trusting the equipment without understanding its limitations is a common mistake. Acknowledging these pitfalls is crucial for mitigating risk.

Over-relying on the Oven's Vent

A standard laboratory oven vent is a passive opening designed to let humidity and small amounts of fumes escape. It is not a substitute for active ventilation.

The vent does not provide adequate protection when working with substances that release significant quantities of toxic or flammable vapors.

Using the Wrong Equipment for the Job

Standard ovens are designed for drying and sterilizing non-volatile materials. Using one to heat volatile chemicals is a dangerous misuse of the equipment.

For applications involving volatile substances, a vacuum oven or placing the entire standard oven within a certified fume hood is the correct protocol.

A Practical Safety Checklist for Oven Use

To ensure safe operation, integrate the following checks into your standard laboratory procedures.

- If you are preparing materials for the oven: Thoroughly clean all glassware and containers to remove any residue from volatile solvents or chemicals.

- If you are heating any substance that could release vapors: Confirm the material's properties. If there is any risk of toxic or flammable fumes, you must operate the oven inside a laboratory fume hood.

- If you are handling hot items: Always use appropriate PPE, including thermal-resistant gloves and safety glasses, to prevent burns and injury.

- If you are using an older oven: Be aware of potential insulation hazards. Avoid any maintenance that could disturb the insulation and consult a safety professional before decommissioning the unit.

Proactive risk assessment and a deep understanding of your materials are the foundation of safe laboratory oven operation.

Summary Table:

| Hazard Category | Key Risks | Mitigation Tips |

|---|---|---|

| Thermal | Severe burns from hot surfaces/contents | Always use heat-resistant gloves and safety glasses |

| Chemical | Release of toxic fumes or flammable vapors | Clean glassware thoroughly; use inside a fume hood for volatile substances |

| Fire/Explosion | Ignition of flammable materials | Never heat flammable solvents or materials that produce flammable vapors |

| Material Degradation | Respirable fibers from old insulation (e.g., ceramic fiber, asbestos) | Avoid disturbing insulation; consult a professional for maintenance/decommissioning |

Ensure your lab's safety with the right equipment from KINTEK.

Laboratory ovens are essential, but using the wrong type or an outdated model can expose your team to serious risks. KINTEK specializes in providing safe, reliable lab equipment and consumables tailored to your specific processes.

We can help you select the perfect oven for your application—whether it's a standard model for drying or a vacuum oven for sensitive materials—ensuring you have the right tool to mitigate hazards. Our experts are ready to assist you in creating a safer, more efficient laboratory environment.

Contact KINTEK today for a consultation and let us help you protect your people and your research.

Visual Guide

Related Products

- Laboratory Scientific Electric Heating Blast Drying Oven

- 1200℃ Muffle Furnace Oven for Laboratory

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

- Custom PTFE Teflon Parts Manufacturer PTFE Beaker and Lids

People Also Ask

- What is the function of a laboratory drying oven in Zr2.5Nb alloy pretreatment? Ensure Precise Corrosion Test Results

- What role does a laboratory drying oven play in the processing and chemical analysis of aluminum dross?

- How does a laboratory constant temperature drying oven contribute to the processing of synthesized Zinc Oxide precipitates?

- What is the role of a laboratory drying oven in catalyst treatment? Ensure Structural Integrity & High Performance

- What is the role of a blast drying oven in COF synthesis? Driving High-Crystallinity Solvothermal Reactions