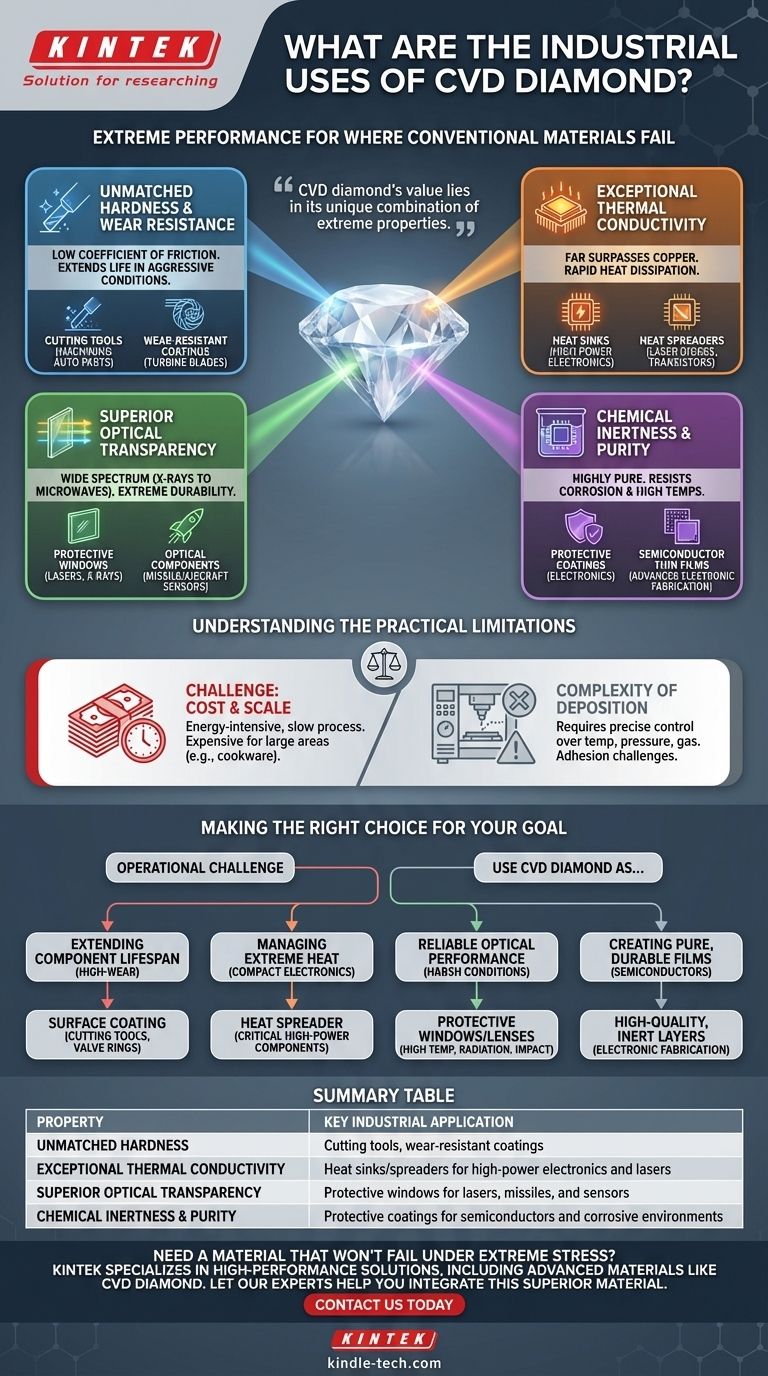

In short, Chemical Vapor Deposition (CVD) diamond is used across industries wherever extreme performance is required. Its primary applications leverage its unparalleled hardness for cutting tools and wear-resistant coatings, its exceptional thermal conductivity for heat sinks in high-power electronics, and its broad optical transparency for protective windows in harsh environments like lasers and missile systems.

The core reason for CVD diamond's industrial value is not a single feature, but its unique combination of extreme properties. It is a material of last resort, chosen when conventional materials fail under intense mechanical, thermal, or optical stress.

Why CVD Diamond? The Foundation of its Versatility

The industrial uses of CVD diamond are a direct result of its physical properties, which are nearly identical to those of a natural, single-crystal diamond. Understanding these properties is key to understanding its applications.

Unmatched Hardness and Wear Resistance

Diamond's extreme hardness and low coefficient of friction make it the ultimate material for applications involving abrasion and wear.

CVD allows this hardness to be applied as a thin, durable film onto other materials. This extends the life of components in aggressive operating conditions, from machining auto parts with diamond-coated tools to protecting turbine blades from severe attrition.

Exceptional Thermal Conductivity

CVD diamond is one of the most thermally conductive materials known, far surpassing copper. It excels at rapidly drawing heat away from a source.

This property is critical for thermal management in high-power electronics. It is used as a heat sink or "heat spreader" for sensitive components like high-frequency transistors and laser diodes, preventing them from overheating and failing.

Superior Optical Transparency

CVD diamond is transparent across an incredibly wide range of the electromagnetic spectrum, from X-rays to microwaves. It is also extremely durable.

This combination makes it the ideal material for protective windows and optical components in demanding environments. Applications include laser windows, X-ray windows, and protective domes for sensors on missiles and aircraft where high-speed impacts could destroy other materials.

Chemical Inertness and Purity

CVD diamond films are highly pure and chemically inert, resisting corrosion and high temperatures.

This makes them excellent protective coatings for electronic components, shielding them from moisture and corrosive agents. In the semiconductor industry, this purity is essential for creating high-performance thin films without introducing contaminants.

Understanding the Practical Limitations

While its properties are exceptional, CVD diamond is not a universal solution. Its adoption is governed by significant practical and economic trade-offs.

The Challenge of Cost and Scale

The primary barrier to wider adoption is cost. The CVD process is energy-intensive and slow, making the resulting material expensive compared to alternatives.

Coating very large surface areas, such as for consumer cookware, remains economically challenging. Its use is therefore concentrated in high-value applications where performance justifies the expense.

The Complexity of Deposition

Applying a uniform, high-quality diamond film requires precise control over temperature, pressure, and gas chemistry.

This complexity can limit the types of shapes and substrates that can be effectively coated. Adhesion of the diamond film to the underlying material is also a critical engineering challenge that must be solved for each specific application.

Making the Right Choice for Your Goal

Selecting CVD diamond depends entirely on whether the operational challenge justifies the investment in a premium material.

- If your primary focus is extending component lifespan in high-wear environments: Use CVD diamond as a surface coating for cutting tools, valve rings, and other parts subject to extreme abrasion.

- If your primary focus is managing extreme heat in compact electronics: Use CVD diamond as a heat spreader to protect critical high-power components from thermal failure.

- If your primary focus is reliable optical performance in harsh conditions: Use CVD diamond for protective windows or lenses that must withstand high temperatures, radiation, or physical impact.

- If your primary focus is creating pure, durable films for semiconductors: Use the CVD process to deposit high-quality, inert layers for advanced electronic fabrication.

Ultimately, CVD diamond is the definitive engineering solution for problems where performance cannot be compromised.

Summary Table:

| Property | Key Industrial Application |

|---|---|

| Unmatched Hardness | Cutting tools, wear-resistant coatings for machinery parts |

| Exceptional Thermal Conductivity | Heat sinks/spreaders for high-power electronics and lasers |

| Superior Optical Transparency | Protective windows for lasers, missiles, and sensors |

| Chemical Inertness & Purity | Protective coatings for semiconductors and corrosive environments |

Need a material that won't fail under extreme stress? CVD diamond is the ultimate solution for high-wear, high-heat, and harsh-environment applications where conventional materials fall short. At KINTEK, we specialize in high-performance lab equipment and consumables, including advanced materials like CVD diamond for industrial and research use. Let our experts help you integrate this superior material into your next project—contact us today to discuss your specific needs!

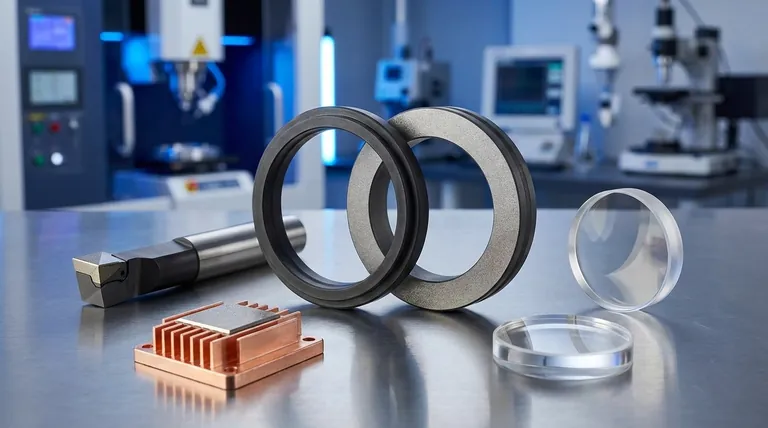

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- CVD Diamond Optical Windows for Lab Applications

- Laboratory CVD Boron Doped Diamond Materials

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- How are CVD lab diamonds made? Discover the Science Behind Lab-Grown Gems

- Which is better lab grown or natural diamond? A Clear Guide to Choosing Your Perfect Stone

- How are lab-grown diamonds created? Discover the HPHT and CVD Manufacturing Process

- What's the difference between CVD and HPHT? Choosing the Right Lab-Grown Diamond Method

- What are the industrial uses of synthetic diamonds? Unlock High-Performance Solutions for Your Tech Needs

- What is the difference between MPCVD and HFCVD? Choose the Right CVD Method for Your Application

- Do natural diamonds last longer? The Truth About Diamond Durability and Value

- Can lab-grown diamonds be GIA certified? Yes, and here’s what you need to know.