When selecting a circulating pump, your decision must be grounded in two primary system calculations: the required flow rate and the total head pressure. These metrics define your system's demand. Beyond these, factors like material compatibility, motor type, and pump configuration determine the pump's efficiency, longevity, and suitability for the specific fluid being moved.

The core challenge in selecting a circulator is not merely identifying these factors, but accurately calculating them for your specific system. The most common and costly error is oversizing the pump, which leads to inefficiency, noise, and premature wear. Your goal is to perfectly match the pump's performance to the system's actual needs.

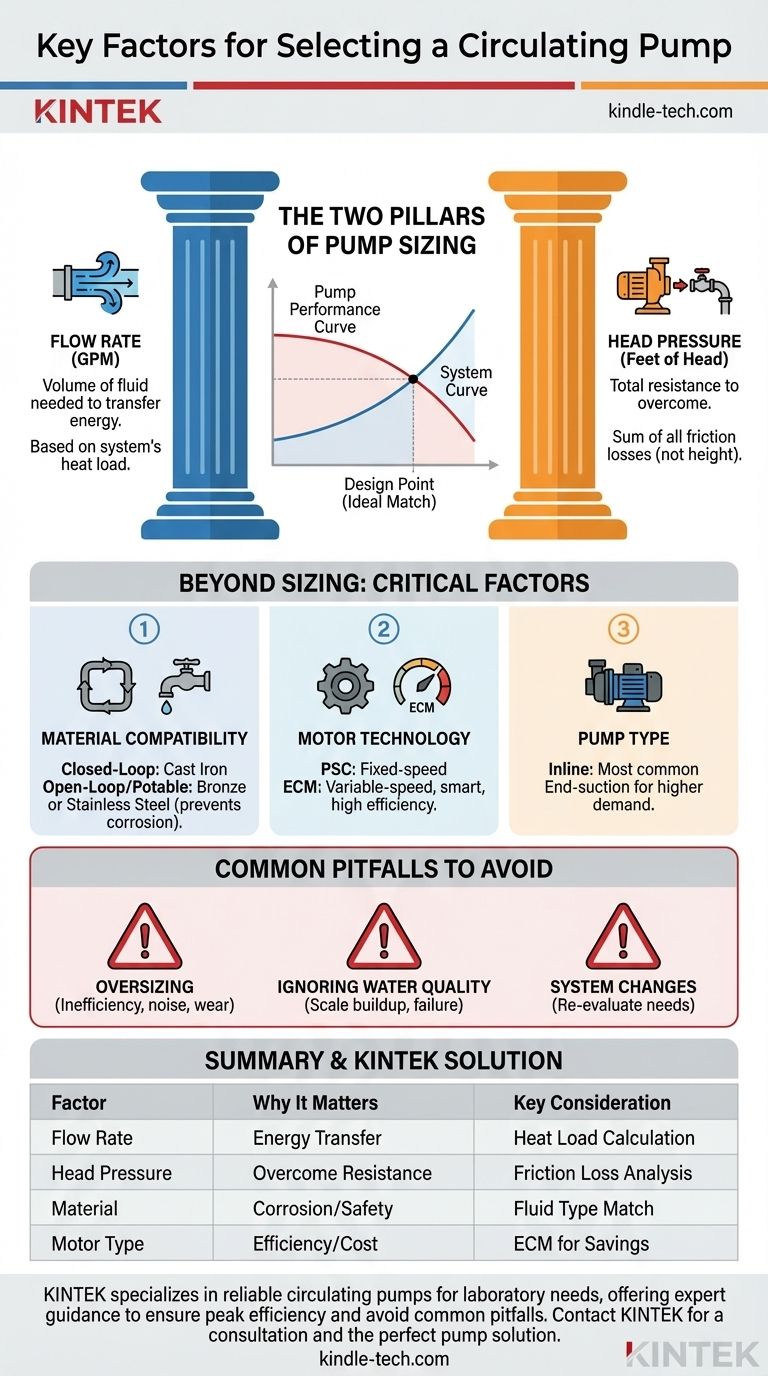

The Two Pillars of Pump Sizing: Flow and Head

A circulating pump doesn't create pressure; it imparts energy to overcome the system's resistance to flow. Understanding the relationship between flow rate and this resistance (head) is the foundation of proper selection.

Calculating Your Required Flow Rate (GPM)

The flow rate, measured in Gallons Per Minute (GPM), is the volume of fluid that needs to move through the circuit to transfer the required amount of energy.

For hydronic heating or cooling systems, this is determined by the heat load. You cannot choose a flow rate arbitrarily; it must be calculated based on the energy demand of the space you are conditioning.

Calculating System Head Pressure (Feet of Head)

Head pressure is the total resistance the pump must overcome to achieve the target flow rate. It is not a measure of the building's height, but rather the sum of all friction losses in the system.

This resistance comes from the fluid moving through pipes, valves, fittings, and heat exchangers. An accurate calculation requires a detailed analysis of the entire piping loop, a process known as calculating head loss.

The Pump Curve: Where Flow Meets Head

Every pump has a performance curve chart provided by the manufacturer. This curve shows the inverse relationship between the flow rate the pump can produce and the head pressure it can overcome.

To select a pump, you find your system's required flow rate and head pressure on this chart. The ideal pump is one whose curve passes directly through this "design point," ensuring it will operate at or near its best efficiency point.

Beyond Sizing: Critical Supporting Factors

Once you've determined your performance requirements, these secondary factors refine your choice for long-term reliability and efficiency.

Material Compatibility

The pump's construction materials must match the fluid. In a standard closed-loop hydronic system with treated water, a cast iron pump is typically sufficient.

For open-loop systems or those circulating potable (drinking) hot water, you must use a bronze or stainless steel pump to prevent corrosion and ensure water safety.

Motor Technology and Efficiency

Modern pumps primarily use two types of motors. A standard PSC (Permanent Split Capacitor) motor is a simple, fixed-speed design.

An ECM (Electronically Commutated Motor) offers significant advantages. These "smart" pumps are variable-speed, consuming far less electricity by automatically adjusting their output to match the system's real-time demand.

Pump Type and Orientation

For most residential and light commercial applications, the standard choice is an inline circulator. These pumps are compact and designed to be mounted directly into the pipeline.

Other types, like end-suction or close-coupled pumps, are typically reserved for larger commercial and industrial systems with much higher flow and head requirements.

Understanding the Trade-offs and Common Pitfalls

Avoiding common mistakes is as important as understanding the technical specifications. A poor choice can compromise the entire system.

The High Cost of Oversizing

Selecting a pump that is too powerful is the most frequent mistake. An oversized pump not only wastes significant energy but also creates high fluid velocity, which can cause pipe erosion, system noise, and excessive wear on bearings and seals.

The Myth of "Maintenance-Free"

While modern circulators are highly reliable, they are not immune to system conditions. Poor water quality can lead to mineral and scale buildup inside the pump, impeding performance and causing seals to fail. Regular checks of system water are critical.

Ignoring System Changes

A pump is selected for a specific system. If you later add a new heating zone, change pipe sizes, or replace radiators, the system's head and flow requirements will change. This may require re-evaluating your pump to ensure it can still meet the demand efficiently.

Making the Right Choice for Your System

Use your system's goals to guide your final selection.

- If your primary focus is energy efficiency and long-term savings: Choose a variable-speed ECM pump that can intelligently adapt to system demand.

- If you are replacing a pump in a simple, existing system: Match the performance of the old pump, but first, verify the head and flow calculations to avoid repeating a past sizing error.

- If you are designing a new, multi-zone hydronic system: Invest the time in precise head loss calculations and select a "smart" ECM pump that can handle varying loads.

- If your system handles potable hot water or is an open loop: A bronze or stainless steel pump is non-negotiable for corrosion resistance and health safety.

A properly selected circulator is the silent, efficient heart of your system; choosing it with care ensures its health and longevity.

Summary Table:

| Key Factor | Why It Matters | Key Consideration |

|---|---|---|

| Flow Rate (GPM) | Determines the volume of fluid needed to transfer energy. | Must be calculated based on the system's heat load, not chosen arbitrarily. |

| Head Pressure (Feet of Head) | The total resistance the pump must overcome. | Sum of friction losses from pipes, valves, and fittings. Not building height. |

| Material Compatibility | Prevents corrosion and ensures fluid safety. | Cast iron for closed loops; bronze/stainless steel for potable water/open loops. |

| Motor Type (ECM vs. PSC) | Impacts energy efficiency and operational cost. | ECM motors are variable-speed and adapt to real-time demand for significant energy savings. |

Selecting the right pump is critical for your system's performance and longevity. KINTEK specializes in laboratory equipment and consumables, providing reliable circulating pumps and expert guidance to ensure your lab's fluid systems operate at peak efficiency. Our team can help you avoid common pitfalls like oversizing and ensure material compatibility for your specific application. Contact KINTEK today for a consultation and let us help you find the perfect pump for your laboratory needs.

Visual Guide

Related Products

- 10L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- 100L Chilling Circulator Cooling Water Circulator for Low Temperature Constant Temperature Reaction Bath Water Bath Cooling

- 100L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- 30L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- 50L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

People Also Ask

- What is the role of ULT cooling equipment in gold nanoparticle hydrogel synthesis? Engineering Precise Nano-Architectures

- How can I keep the temperature constant? Master Thermal Equilibrium for Ultimate Stability

- Why is a high-precision constant temperature water bath necessary for anaerobic digestion? Ensure Success at 37±0.02°C

- Why is a dedicated cooling circulation system required for feeding pipes? Ensure Accurate Reaction Kinetics

- What is the importance of a Recirculating Cooling Water System? Protect Your Lab and Master Reaction Control

- Why is the mechanical agitation provided by a shaking incubator necessary for the enzymatic hydrolysis of biomass?

- How does a recirculating cooling system or thermostatic water bath affect the results of the copper anodic oxidation?

- Why is a high-precision temperature control system necessary for evaluating the performance of SAPO-34? Ensure Accuracy