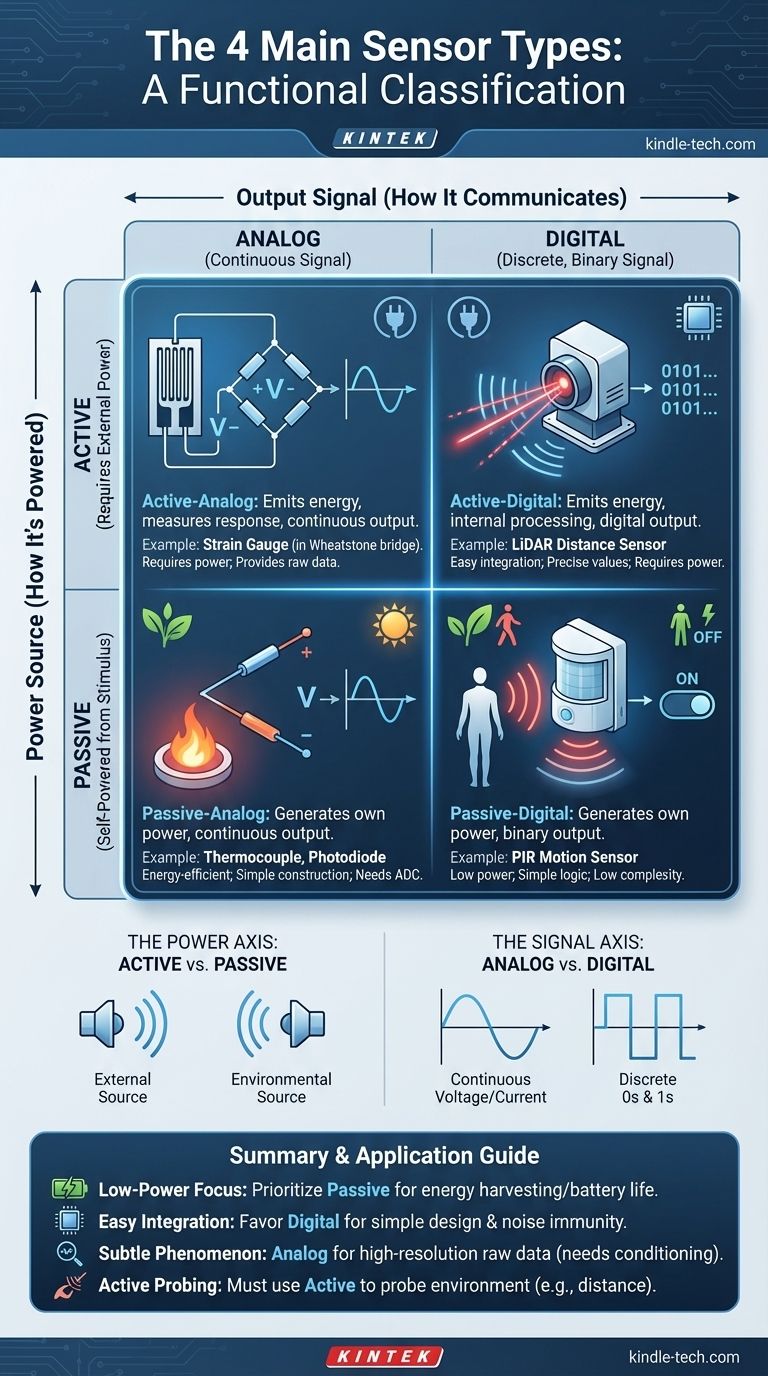

At a fundamental level, sensors are most commonly classified into four categories: Active, Passive, Analog, and Digital. These categories describe two distinct characteristics: how a sensor is powered and how it communicates its measurement. Understanding these two axes is the key to making sense of how any sensor functions.

The core insight is that "four types" is a simplification. In reality, sensors are classified along two independent axes: their power requirement (Active vs. Passive) and their output signal type (Analog vs. Digital). Any given sensor is a combination of one from each pair.

The First Axis: Power Source (Active vs. Passive)

This classification is based on whether a sensor requires an external power source to perform its measurement. It's about energy input.

What Are Active Sensors?

Active sensors require an external power source, often called an excitation signal, to operate. They work by emitting energy into the environment and then measuring the response.

Think of an active sensor like a bat using echolocation. It sends out a signal (a sound) and listens for the echo to "see" its surroundings.

Examples include radar, LiDAR, and ultrasonic distance sensors, which all emit waves to detect objects.

What Are Passive Sensors?

Passive sensors do not require an external power source. Instead, they generate their own electrical signal in response to an external stimulus.

They are self-powered by converting one form of energy from the environment into another. They simply "listen" to or detect existing energy.

A photodiode, which converts light directly into an electrical current, is a classic example. A thermocouple, which generates a voltage based on a temperature difference, is another.

The Second Axis: Output Signal (Analog vs. Digital)

This classification is based on the nature of the signal the sensor sends to the processing unit (like a microcontroller). It's about data output.

Understanding Analog Sensors

Analog sensors produce a continuous output signal, typically a voltage or current, that is proportional to the quantity being measured.

The signal can have any value within the sensor's operating range. For example, a temperature sensor might output 0.1V at 10°C, 0.2V at 20°C, and 0.15V at 15°C.

Common examples include thermistors (temperature-sensitive resistors), Light Dependent Resistors (LDRs), and basic pressure sensors.

Understanding Digital Sensors

Digital sensors produce a discrete, binary output. The signal is communicated as a series of on/off states (1s and 0s).

These sensors often have internal components, like an Analog-to-Digital Converter (ADC), that process the raw measurement before sending a clean, digital value.

Examples include modern temperature/humidity sensors like the DHT22 or high-precision accelerometers that communicate over interfaces like I2C or SPI.

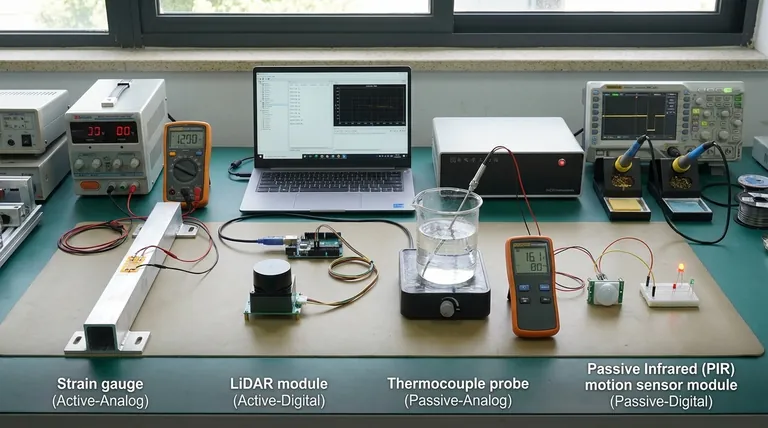

Putting It All Together: The Four Quadrants

Since the two axes are independent, you can combine them to form four true functional quadrants.

Active-Analog

This sensor requires external power and outputs a continuous signal. A strain gauge used in a Wheatstone bridge is a perfect example; it needs an input voltage (Active) and produces a proportional output voltage (Analog).

Active-Digital

This sensor requires external power and outputs a digital signal. A LiDAR sensor emits its own laser pulses (Active) and contains internal processors to output a precise digital distance value (Digital).

Passive-Analog

This sensor generates its own power and outputs a continuous signal. A thermocouple creates a voltage from heat (Passive) that is directly proportional to the temperature difference (Analog).

Passive-Digital

This sensor generates its own power and outputs a binary signal. A common Passive Infrared (PIR) motion sensor detects infrared energy from body heat (Passive) and outputs a simple high/low signal to indicate motion (Digital).

Understanding the Trade-offs

Choosing a sensor isn't just about what it measures, but how it operates. These classifications have direct practical implications.

Power Consumption

Passive sensors are inherently more energy-efficient because they don't need a constant power source for excitation. This makes them ideal for battery-powered or energy-harvesting applications.

Complexity and Noise

Digital sensors are often easier to integrate with modern microcontrollers. They handle the conversion from a physical phenomenon to a digital number internally, providing a clean, noise-resistant signal.

Analog sensors require an ADC on your microcontroller and their signals are more susceptible to electrical noise, which can degrade accuracy if not properly filtered.

Cost and Functionality

The choice can impact cost and features. A simple analog thermistor is very cheap, but a high-precision digital temperature sensor might be more expensive while offering higher accuracy and easier integration.

How to Apply This to Your Project

Use these classifications as a framework to guide your selection process.

- If your primary focus is low-power operation: Prioritize Passive sensors to maximize battery life or enable energy harvesting.

- If your primary focus is easy integration and noise immunity: Favor Digital sensors to simplify your circuit design and software development.

- If your primary focus is measuring a subtle, continuous phenomenon: An Analog sensor may provide the raw, high-resolution data you need, assuming you can properly condition and process the signal.

- If your primary focus is actively probing the environment: You inherently need an Active sensor, such as for measuring distance with ultrasound or scanning a room with LiDAR.

Understanding these two axes—power source and signal type—moves you from simply listing sensor types to strategically selecting the right tool for your engineering challenge.

Summary Table:

| Sensor Type | Power Source | Output Signal | Key Examples |

|---|---|---|---|

| Active-Analog | Requires external power | Continuous (e.g., voltage) | Strain gauge in a Wheatstone bridge |

| Active-Digital | Requires external power | Discrete (binary, e.g., I2C/SPI) | LiDAR distance sensor |

| Passive-Analog | Self-powered (from stimulus) | Continuous (e.g., voltage) | Thermocouple, Photodiode |

| Passive-Digital | Self-powered (from stimulus) | Discrete (binary, on/off) | PIR motion sensor |

Ready to select the perfect sensor for your laboratory application? The right sensor is critical for accurate data collection and experimental success. KINTEK specializes in high-quality lab equipment and consumables, serving researchers and laboratory professionals. Our experts can help you navigate sensor specifications—from power requirements to signal output—ensuring you get reliable, precise instrumentation for your unique needs. Contact our technical team today for a personalized consultation!

Visual Guide

Related Products

- Lab Electrochemical Workstation Potentiostat for Laboratory Use

- Conductive Carbon Cloth Carbon Paper Carbon Felt for Electrodes and Batteries

- High Temperature Constant Temperature Heating Circulator Water Bath Chiller Circulator for Reaction Bath

- Reference Electrode Calomel Silver Chloride Mercury Sulfate for Laboratory Use

- 100L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

People Also Ask

- What temperature is needed to sinter steel? Optimize Your Process for Strength and Precision

- What varieties of high-temperature furnaces are available? Find the Perfect Lab Furnace for Your Thermal Research

- What is the difference between dry oven and incubator? Choosing the Right Equipment for Your Lab

- How does an Ultrafast High-temperature Sintering (UHS) system work? Achieve 3000°C in Seconds

- What role does a constant temperature orbital shaker play in biomass processing? Maximize Your Fermentation Yields

- Why use high-precision weighing and homogenization for boride shielding? Achieve Superior Lead-Free Radiation Protection

- What are the benefits of vacuum pyrolysis? Maximize Your Bio-Oil Yield and Quality

- What are the main components of biomass? The Key to Unlocking its Energy Potential