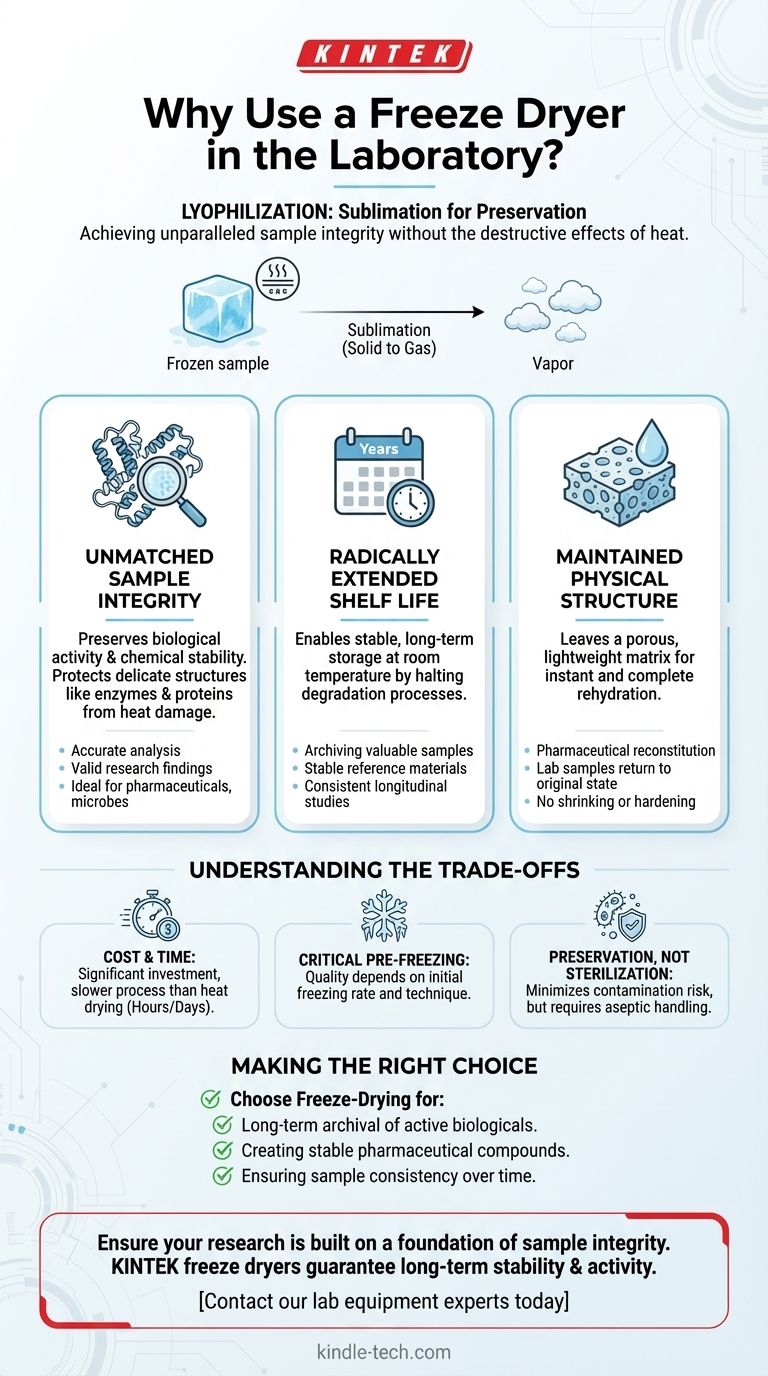

In the laboratory, a freeze dryer is used for three primary reasons: to achieve unparalleled preservation of a sample's biological and chemical integrity, to enable stable long-term storage without refrigeration, and to maintain the sample's physical structure for easy rehydration. This process, also known as lyophilization, removes water by freezing the material and then reducing the pressure to allow the frozen water to sublimate directly from a solid to a gas.

The fundamental value of freeze-drying is its ability to remove moisture without the destructive effects of heat. This preserves the delicate structure and activity of sensitive materials, making it an indispensable tool for reliable and reproducible scientific research.

The Core Principle: Sublimation, Not Evaporation

How Freeze-Drying Works

A laboratory freeze dryer operates on a simple but powerful principle. First, the material is frozen solid. Then, it is placed under a deep vacuum.

Finally, a small amount of heat is introduced, causing the frozen water (ice) to turn directly into vapor without ever passing through a liquid phase. This process is called sublimation.

Why This Protects the Sample

Traditional drying methods use heat to evaporate water. This heat can denature proteins, destroy enzymes, and alter the chemical composition of a sample.

Freeze-drying completely avoids the damaging effects of high temperatures. By keeping the sample frozen throughout the drying process, it locks the material's delicate structures in place, ensuring its biological activity and chemical stability are preserved.

Key Benefits for Laboratory Applications

Unmatched Sample Integrity

For pharmaceuticals, enzymes, microbes, and other biological samples, maintaining their original state is critical. Freeze-drying is the gold standard for this.

It prevents degradation, ensuring that the sample you analyze months or years from now is virtually identical to the one you started with. This is essential for accurate analysis and valid research findings.

Radically Extended Shelf Life

By removing water, freeze-drying halts most biological and chemical processes that cause degradation. This allows samples to be stored for years at room temperature.

This capability is particularly crucial for creating stable reference materials, archiving valuable biological samples, and conducting longitudinal studies where sample consistency over time is non-negotiable.

Maintaining Physical Structure

Unlike heat drying, which can cause materials to shrink and harden, freeze-drying leaves the product's structural matrix intact.

The final product is porous and lightweight, which allows it to be rehydrated almost instantly and completely. This is vital for pharmaceuticals that must be reconstituted before use or for lab samples that need to return to their original state.

Understanding the Trade-offs

The Cost and Time Investment

Freeze dryers are a significant capital investment, and the process itself is much slower than simple heat-based drying. Lyophilization cycles can often take hours or even days to complete.

This method is therefore best reserved for materials where the value of preserving integrity outweighs the need for speed and low cost.

The Critical Pre-Freezing Step

The quality of the final product is heavily dependent on the initial freezing process. The rate at which a sample is frozen affects the ice crystal structure, which in turn impacts the drying process and final product stability.

Proper technique and sometimes specialized pre-freezing equipment are necessary to achieve optimal and repeatable results.

Preservation, Not Sterilization

While a freeze dryer's sealed vacuum system minimizes the risk of contamination during the process, it is not a sterilization method.

The starting material must be handled aseptically if a sterile final product is required. The process will preserve microbes just as effectively as it preserves the sample itself.

Making the Right Choice for Your Research

Choosing a preservation method depends entirely on the nature of your sample and the goals of your work.

- If your primary focus is long-term archival of active biologicals (enzymes, proteins, viruses): Freeze-drying is the superior choice for maintaining biological activity and integrity.

- If your primary focus is creating stable pharmaceutical compounds: Freeze-drying preserves the chemical structure and physical form needed for accurate dosing and rapid reconstitution.

- If your primary focus is sample consistency for longitudinal studies: The stability offered by freeze-drying is essential for generating reliable data over extended periods.

- If your primary focus is simple water removal from non-sensitive materials: A less complex and more rapid method, such as a vacuum oven or desiccator, may be a more practical and cost-effective solution.

Ultimately, freeze-drying empowers researchers by preserving the true state of their samples, ensuring that their findings are both accurate and reproducible.

Summary Table:

| Key Reason | Core Benefit | Ideal For |

|---|---|---|

| Unmatched Sample Integrity | Preserves biological activity & chemical structure | Pharmaceuticals, enzymes, proteins, microbes |

| Extended Shelf Life | Stable storage for years at room temperature | Reference materials, archiving, longitudinal studies |

| Maintained Physical Structure | Porous product for instant, complete rehydration | Samples requiring reconstitution, like pharmaceuticals |

Ensure your research is built on a foundation of sample integrity.

Freeze-drying with a KINTEK laboratory freeze dryer guarantees the long-term stability and activity of your most sensitive materials—from proteins and enzymes to critical pharmaceuticals. Our equipment is designed to deliver the precise control and reliable performance your work demands.

Contact our lab equipment experts today to discuss how a KINTEK freeze dryer can protect your research investment and enhance your lab's capabilities.

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

People Also Ask

- What are amorphous materials in freeze drying? The Key to Preventing Product Collapse

- What can I use instead of rotavap? Find the Perfect Solvent Removal Tool for Your Lab

- What is the freeze drying or lyophilisation process? A Guide to Gentle, High-Quality Dehydration

- Which industries commonly utilize freeze drying techniques? The Key to Preserving High-Value Products

- Where are evaporators used in food industry? Concentrate Products & Reduce Costs