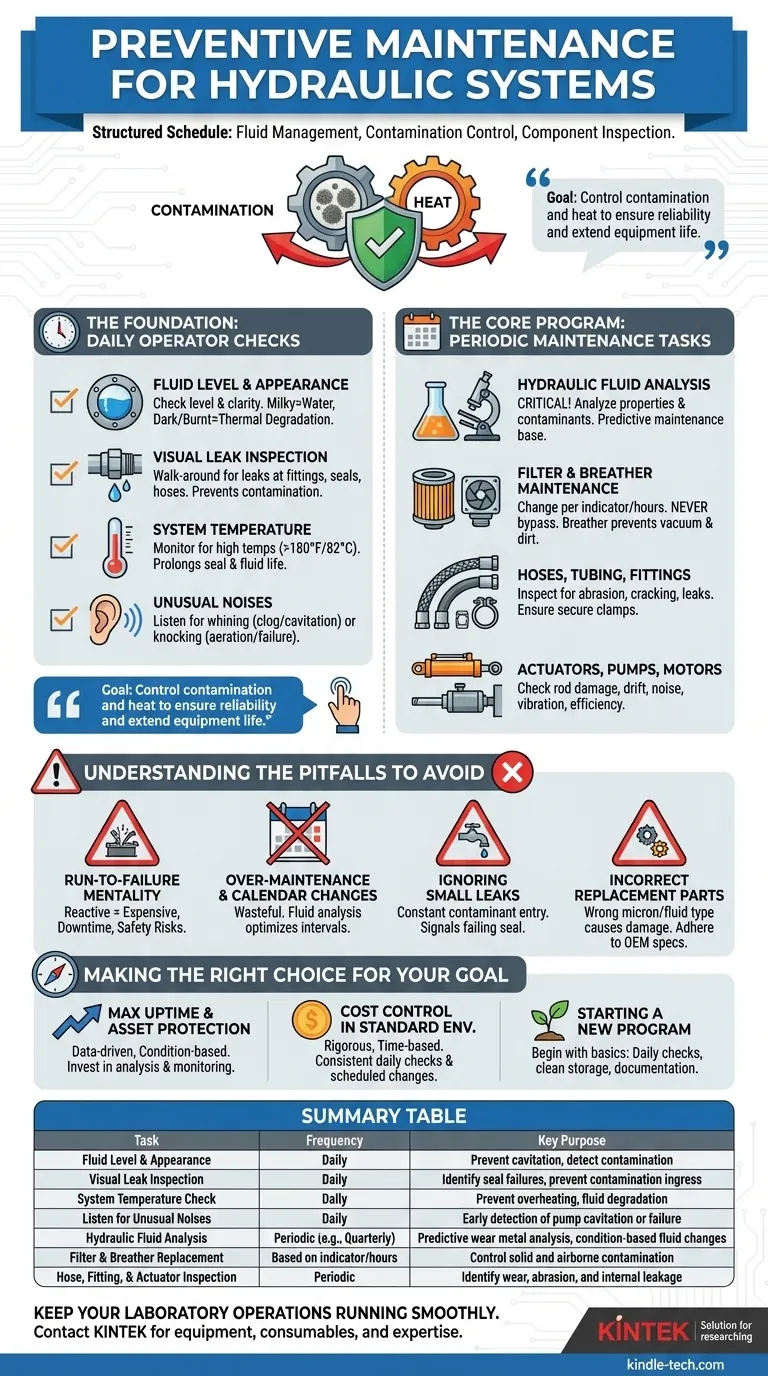

A comprehensive preventive maintenance program for a hydraulic system is built on a structured schedule of tasks focused on fluid management, contamination control, and component inspection. The core activities include regular fluid analysis, filter and breather replacement, visual inspection of hoses and seals for leaks or wear, and operational checks of temperature, pressure, and actuator performance.

The goal of preventive maintenance is not simply to follow a checklist, but to fundamentally control the two primary enemies of any hydraulic system: contamination and heat. A disciplined program transforms maintenance from a reactive expense into a proactive strategy for ensuring reliability and extending equipment life.

The Foundation: Daily Operator Checks

These simple, consistent checks form the first line of defense against catastrophic failure. They should be performed by the machine operator at the start of every shift.

Fluid Level and Appearance

The hydraulic reservoir's sight glass should be checked to ensure the fluid is at the correct operating level. Low fluid levels can cause pump cavitation and system overheating.

The fluid's appearance should also be noted. Cloudy or milky fluid indicates water contamination, while a darkened color and burnt smell suggest thermal degradation or oxidation.

Visual Leak Inspection

A walk-around inspection should be performed to identify any leaks at fittings, seals, hoses, or components. Even a small leak can allow contaminants to enter the system and signifies a failing seal.

System Temperature

Check the system's temperature gauge or use an infrared temperature gun on the reservoir. Consistently high operating temperatures (typically above 180°F or 82°C) drastically shorten the life of seals and hydraulic fluid.

Unusual Noises

Listen for changes in the sound of the system. High-pitched whining often points to a clogged suction filter or pump cavitation, while knocking sounds can indicate aeration or failing components.

The Core Program: Periodic Maintenance Tasks

These tasks require more time and skill than daily checks and are typically performed on a weekly, monthly, or quarterly basis, depending on the equipment's duty cycle and operating environment.

Hydraulic Fluid Analysis

This is the single most important task in a predictive maintenance program. A fluid sample is sent to a lab to analyze its properties and identify contaminants.

Fluid analysis reveals critical information about wear metals (indicating component failure), water content, viscosity, and overall fluid health. This data allows you to change fluid based on its actual condition, not just an arbitrary schedule.

Filter and Breather Maintenance

Hydraulic filters capture solid contaminants. They should be changed based on the filter indicator or after a set number of operating hours. Never let a filter go into bypass mode, as this allows dirty fluid to circulate freely.

The reservoir breather is equally important. It filters the air that enters the reservoir as the fluid level changes. A clogged breather can create a vacuum, straining the pump and pulling contaminants past seals.

Hoses, Tubing, and Fittings

Inspect all fluid conductors for signs of abrasion, cracking, blistering, or kinking. Ensure all clamps are secure and that hoses are not rubbing against each other or machine components. Check all fittings for tightness and signs of leakage.

Actuators (Cylinders and Motors)

Inspect cylinder rods for pitting, corrosion, or scoring, which can damage rod seals. Check for "actuator drift"—when a cylinder or motor moves under load with the control valve in the neutral position—as this indicates internal leakage past the piston seals.

Pumps and Motors

Listen for changes in noise or vibration, which can signal bearing failure or cavitation. Ensure mounting bolts are secure. If possible, perform efficiency tests to measure internal leakage (flow loss), which is a key indicator of wear.

Understanding the Pitfalls to Avoid

An effective program requires avoiding common but costly mistakes. True reliability comes from understanding the principles behind the tasks.

The "Run-to-Failure" Mentality

The most common mistake is viewing maintenance as a pure cost center and deferring it until a component fails. This approach is almost always more expensive due to unplanned downtime, collateral damage to other components, and safety risks.

Over-Maintenance and Calendar-Based Changes

Blindly changing hydraulic fluid on a calendar schedule without fluid analysis is wasteful and can even introduce contamination. Fluid analysis is the key to optimizing change intervals and catching problems before they escalate.

Ignoring Small Leaks

A "weeping" fitting or a "minor" drip is often ignored, but it represents a significant problem. It is a constant entry point for dirt and moisture and a clear sign that a seal or connection is failing.

Using Incorrect Replacement Parts

Using a filter with the wrong micron rating or a fluid that doesn't meet OEM specifications can cause significant damage. Always adhere to the manufacturer's recommendations for fluid type, viscosity, and filtration levels.

Making the Right Choice for Your Goal

Your maintenance strategy should align with your operational priorities.

- If your primary focus is maximum uptime and asset protection: Prioritize a data-driven, condition-based program. Invest in regular fluid analysis and condition monitoring tools (like temperature and vibration sensors) to predict failures.

- If your primary focus is cost control in a standard environment: Implement a rigorous, time-based program focusing on the fundamentals. Ensure daily checks are done consistently and filters are changed on schedule without fail.

- If you are just starting a new maintenance program: Begin with the basics. Enforce daily operator inspections, start a clean and organized fluid storage and handling practice, and begin documenting all maintenance activities and failures.

A consistent and well-documented preventive maintenance strategy transforms your hydraulic system from a potential liability into a predictable and reliable asset.

Summary Table:

| Maintenance Task | Frequency | Key Purpose |

|---|---|---|

| Fluid Level & Appearance Check | Daily | Prevent cavitation, detect contamination |

| Visual Leak Inspection | Daily | Identify seal failures, prevent contamination ingress |

| System Temperature Check | Daily | Prevent overheating, fluid degradation |

| Listen for Unusual Noises | Daily | Early detection of pump cavitation or failure |

| Hydraulic Fluid Analysis | Periodic (e.g., Quarterly) | Predictive wear metal analysis, condition-based fluid changes |

| Filter & Breather Replacement | Based on indicator/hours | Control solid and airborne contamination |

| Hose, Fitting, & Actuator Inspection | Periodic | Identify wear, abrasion, and internal leakage |

Keep your laboratory operations running smoothly and efficiently. A well-maintained hydraulic system is critical for the reliability of your lab equipment. KINTEK specializes in providing the lab equipment and consumables you need to support your maintenance programs. Our experts can help you select the right supplies and understand best practices to protect your investment and minimize downtime.

Contact our team today to discuss your laboratory's specific needs and ensure your systems operate at peak performance.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is the significance of using laboratory hydraulic pressure testing equipment? Ensure Glass Matrix Stability

- How are samples prepared for XRF analysis? Achieve Accurate and Reliable Results

- What is the role of KBr in IR? Achieve High-Resolution Spectra for Solid Samples

- Why is a laboratory pressure testing machine essential for nano-carbon-cement? Validate High-Performance Composites

- Why use 500 MPa pressure for BZCY72 electrolytes? Achieve 95% Theoretical Density with High-Pressure Hydraulic Presses

- Is there anything that can survive a hydraulic press? A Guide to Material Strength & Physics

- How do you control pressure in a hydraulic system? Master Flow Resistance for Optimal Performance

- How does a laboratory powder pellet press facilitate the preparation of multi-layered gradient Al2O3/ZrO2 ceramic green bodies? Precision Bonding Techniques