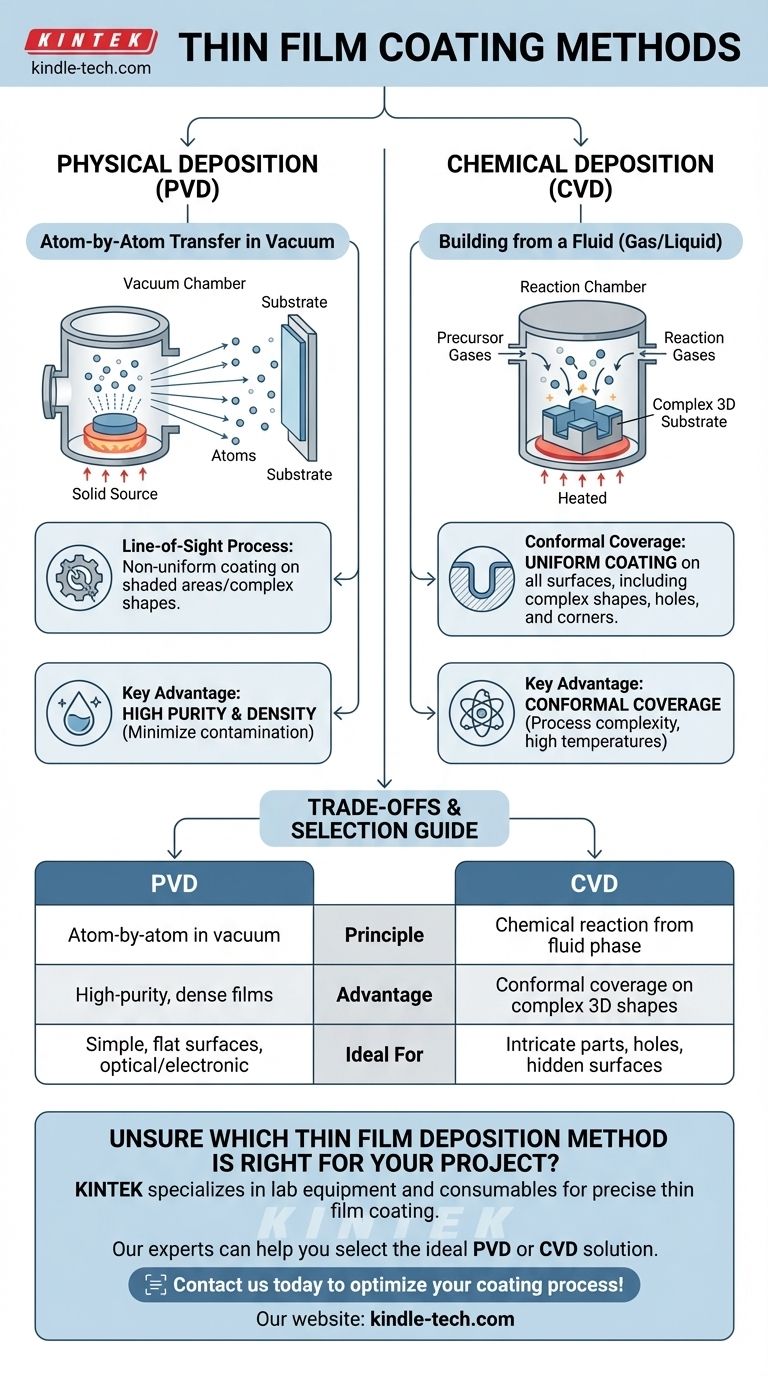

At its core, there are two primary methods for applying thin film coatings: Physical Deposition and Chemical Deposition. Physical methods transfer material to a surface (the substrate) through mechanical or thermodynamic means in a vacuum, while chemical methods use a fluid-based chemical reaction to grow the film directly onto the substrate's surface.

The fundamental choice between coating methods is a strategic one. It is not about which is "better," but which process aligns with the geometry of your part and the specific properties you need the final film to possess.

Understanding Physical Deposition

Physical Deposition, often called Physical Vapor Deposition (PVD), encompasses a family of processes that create a film by depositing atoms or molecules from a vapor phase onto a substrate.

The Core Principle: Atom by Atom

In PVD, a solid source material (like a metal or ceramic) is converted into a gaseous vapor within a low-pressure vacuum chamber. This vapor then travels and condenses onto the cooler substrate, building the thin film one atom at a time.

The process is purely physical; the material's chemical composition does not change during transfer from the source to the substrate.

A "Line-of-Sight" Process

A defining characteristic of PVD is that it is a "line-of-sight" technique. The vaporized atoms travel in a relatively straight line from the source to the substrate.

This means that surfaces directly facing the source material receive a thick, dense coating, while surfaces that are shadowed or angled away receive a much thinner coating, or none at all.

Exploring Chemical Deposition

Chemical Deposition methods use controlled chemical reactions to synthesize a film directly on the substrate's surface, typically from precursor gases or a liquid solution.

The Core Principle: Building from a Fluid

In a typical Chemical Deposition process, such as Chemical Vapor Deposition (CVD), the substrate is placed in a reaction chamber and exposed to one or more volatile precursor gases.

These gases react or decompose on the substrate's hot surface, leaving behind a solid film of the desired material. Other methods involve submerging the substrate in a chemical fluid bath.

Conformal Coverage is Key

The most significant advantage of chemical methods is their ability to produce a conformal coating.

Because the precursor gases or liquids surround the entire substrate, the film grows uniformly on all surfaces, including complex 3D shapes, sharp corners, and even the inside of small holes. This is something PVD methods struggle to achieve.

Understanding the Trade-offs

Choosing the correct method requires understanding the inherent compromises of each approach. This decision directly impacts the film's performance, cost, and applicability.

Physical Deposition: Purity vs. Coverage

PVD processes excel at creating films of extremely high purity and density, as the vacuum environment minimizes contamination. This makes it ideal for optical and electronic applications.

However, its line-of-sight nature makes it unsuitable for uniformly coating complex, non-planar geometries.

Chemical Deposition: Conformality vs. Complexity

The primary strength of Chemical Deposition is its unparalleled ability to create uniform, conformal coatings on intricate parts.

The trade-off is often process complexity. These methods can require high temperatures that not all substrates can withstand, and byproducts from the chemical reactions can sometimes become incorporated into the film as impurities.

Making the Right Choice for Your Goal

Your application's specific requirements for film properties and component geometry should dictate your choice of deposition method.

- If your primary focus is coating a simple, flat surface with a high-purity material: Physical Vapor Deposition (PVD) is the most direct and effective method.

- If your primary focus is uniformly coating a complex 3D object with intricate features: Chemical Deposition (like CVD) is the necessary approach due to its conformal nature.

- If your primary focus is protecting a component from corrosion or wear: Both methods are viable, but the choice will depend on whether the part's geometry requires the conformal coverage of Chemical Deposition.

Selecting the right coating process begins with a clear understanding of your end goal.

Summary Table:

| Method | Key Principle | Key Advantage | Ideal For |

|---|---|---|---|

| Physical Vapor Deposition (PVD) | Atom-by-atom transfer in a vacuum | High-purity, dense films | Simple, flat surfaces; optical/electronic applications |

| Chemical Vapor Deposition (CVD) | Chemical reaction from a fluid phase | Conformal coverage on complex 3D shapes | Intricate parts with holes, corners, and hidden surfaces |

Unsure which thin film deposition method is right for your project?

KINTEK specializes in lab equipment and consumables for precise thin film coating. Our experts can help you select the ideal PVD or CVD solution to achieve the specific film properties—whether for purity, conformality, or durability—that your laboratory requires.

Contact us today to discuss your application and optimize your coating process!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings