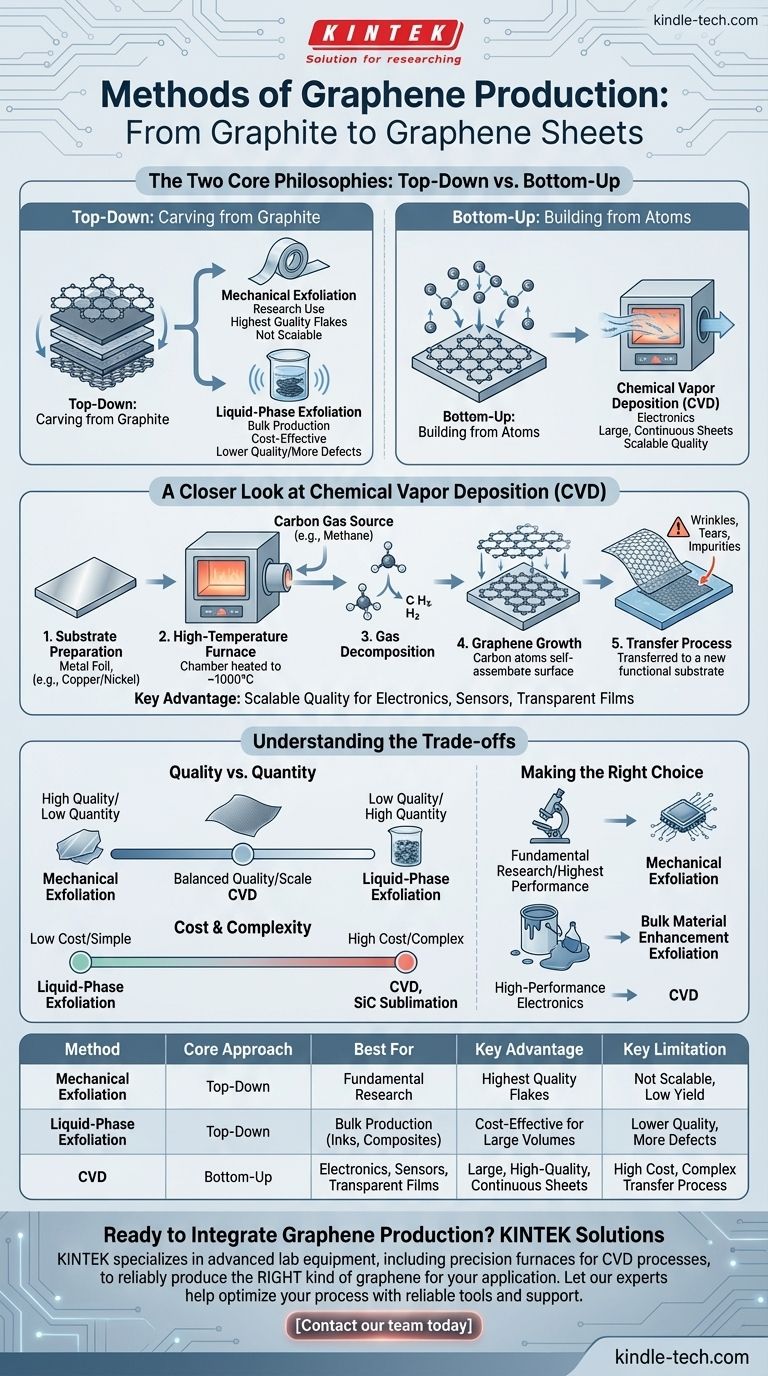

At its core, graphene production is divided into two fundamental strategies: "top-down" methods that start with graphite and break it down, and "bottom-up" methods that build graphene atom by atom. The most prominent methods include mechanical exfoliation for research, liquid-phase exfoliation for bulk production, and Chemical Vapor Deposition (CVD), which has emerged as the leading technique for creating large, high-quality sheets suitable for advanced electronics.

The central challenge in graphene production is not simply making it, but making the right kind of graphene for a specific purpose. The choice of method involves a critical trade-off between the final material's quality, the scale of production, and the overall cost.

The Two Core Philosophies: Top-Down vs. Bottom-Up

Understanding the method starts with understanding the approach. Every technique falls into one of two categories, each with distinct advantages and limitations.

Top-Down: Carving from Graphite

This approach is conceptually simple: you take a block of graphite (which is essentially a stack of countless graphene layers) and separate those layers.

Mechanical exfoliation is the original, Nobel Prize-winning technique. It involves using adhesive tape to peel away layers from graphite until you are left with a single, one-atom-thick sheet. While this produces exceptionally high-quality graphene flakes, the process is manual, yields very small amounts, and is not scalable for commercial use. It remains a vital tool for fundamental scientific research.

Liquid-phase exfoliation aims to solve the scaling issue. In this method, graphite is dispersed in a liquid and subjected to high energy (like sonication) to break the layers apart. This can produce large quantities of graphene flakes, making it suitable for applications like conductive inks, composites, and coatings where bulk material is more important than perfect atomic structure.

Bottom-Up: Building from Atoms

This approach is the reverse of top-down. Instead of starting with a large crystal and breaking it down, you provide carbon atoms and a surface for them to assemble into a perfect graphene lattice.

The most important bottom-up technique is Chemical Vapor Deposition (CVD). It is widely considered the most promising path toward industrial-scale production of high-performance graphene. Other methods in this category include the sublimation of silicon carbide (SiC) and arc discharge, but CVD has become the dominant trend.

A Closer Look at Chemical Vapor Deposition (CVD)

Because of its unique ability to balance quality and scale, CVD warrants a deeper analysis. This method is the primary driver behind graphene's potential use in next-generation electronics.

How the CVD Process Works

The process is a controlled, high-temperature reaction. A substrate, typically a sheet of metal foil like copper or nickel, is placed inside a furnace. The chamber is heated to around 1000°C while a carbon-containing gas, such as methane, is introduced.

At this extreme temperature, the hydrocarbon gas decomposes, freeing individual carbon atoms. These atoms then diffuse and bond to the surface of the metal substrate, self-organizing into the characteristic honeycomb lattice of graphene. This process forms a continuous, single-atom-thick film covering the entire substrate.

The Key Advantage: Scalable Quality

Unlike exfoliation methods that produce small, disconnected flakes, CVD creates large, continuous sheets of high-quality graphene. This makes it the only viable method for applications that require a uniform film over a large area, such as transparent conductive displays, electronic circuits, and advanced sensors.

Controlling the Outcome

Engineers can precisely control the final product by adjusting the process parameters. By managing the temperature, pressure, and flow rate of the gas, it's possible to control the growth and determine whether a single layer or multiple layers of graphene are formed.

Understanding the Trade-offs

No single production method is universally superior. The optimal choice is dictated entirely by the end-use application and its specific requirements.

Quality vs. Quantity

There is a direct trade-off here. Mechanical exfoliation provides pristine, defect-free flakes with the best possible electrical properties, but in microscopic quantities. Liquid-phase exfoliation provides mass quantities of graphene, but the flakes are smaller and have more defects, leading to lower electrical performance. CVD offers the best compromise, producing large sheets with high quality, though not as perfect as the best mechanically exfoliated flakes.

Cost and Complexity

High-quality methods are expensive. CVD and SiC sublimation require specialized, high-temperature furnaces and vacuum equipment, contributing to high costs. In contrast, liquid-phase exfoliation can be done with more common industrial equipment, making it a more cost-effective choice for producing graphene in bulk for less demanding applications.

The Challenge of Transfer

A critical but often overlooked step for CVD graphene is transfer. The graphene is grown on a metal substrate (like copper) but must be moved to a functional substrate (like a silicon wafer) for use in electronics. This delicate transfer process can introduce wrinkles, tears, and impurities, which can degrade the material's performance.

Making the Right Choice for Your Goal

To select the appropriate method, you must first define your primary objective.

- If your primary focus is fundamental research or creating a single prototype device with the highest possible performance: Mechanical exfoliation is the best tool for producing small, ultra-high-quality flakes.

- If your primary focus is bulk production for materials enhancement (e.g., strengthening polymers or creating conductive inks): Liquid-phase exfoliation offers the most cost-effective path to large volumes.

- If your primary focus is creating high-performance electronics, transparent conductors, or sensors: Chemical Vapor Deposition (CVD) is the industry-standard method for growing large, high-quality, uniform films.

Ultimately, the method used to create the graphene fundamentally defines what it can be used for.

Summary Table:

| Method | Core Approach | Best For | Key Advantage | Key Limitation |

|---|---|---|---|---|

| Mechanical Exfoliation | Top-Down | Fundamental Research | Highest Quality Flakes | Not Scalable, Low Yield |

| Liquid-Phase Exfoliation | Top-Down | Bulk Production (Inks, Composites) | Cost-Effective for Large Volumes | Lower Quality, More Defects |

| Chemical Vapor Deposition (CVD) | Bottom-Up | Electronics, Sensors, Transparent Films | Large, High-Quality, Continuous Sheets | High Cost, Complex Transfer Process |

Ready to Integrate Graphene Production into Your Lab Workflow?

Choosing the right production method is critical to your research and development success. KINTEK specializes in providing the advanced lab equipment—including precision furnaces for CVD processes—and consumables needed to reliably produce the right kind of graphene for your specific application, whether you're focused on ultra-high-quality research or scalable material production.

Let our experts help you optimize your process. We understand the trade-offs between quality, scale, and cost, and we can provide the reliable tools and support your laboratory needs to innovate with confidence.

Contact our team today to discuss your project requirements and find the ideal solution for your lab.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

People Also Ask

- How does chirality affect carbon nanotubes? It Determines If They Are Metal or Semiconductor

- What function does CVD equipment serve in rhodium-modified coatings? Achieve Deep Diffusion and Microstructural Precision

- What role does Chemical Vapor Deposition (CVD) equipment play in the preparation of C/C composites? Expert Analysis

- What are the advantages of industrial CVD for solid boriding? Superior Process Control and Material Integrity

- What is a CVD tube furnace? A Complete Guide to Thin-Film Deposition