In essence, the most common heat treatment processes are annealing, hardening, tempering, case hardening, and precipitation hardening. Each process involves a carefully controlled cycle of heating and cooling designed to deliberately alter a metal's internal structure, thereby changing its physical and mechanical properties like hardness, toughness, or ductility to fit a specific engineering requirement.

Heat treatment is not a single action but a suite of precise metallurgical tools. The core principle is simple: by controlling temperature and cooling rates, you control the metal's microscopic crystal structure, which in turn dictates its macroscopic performance.

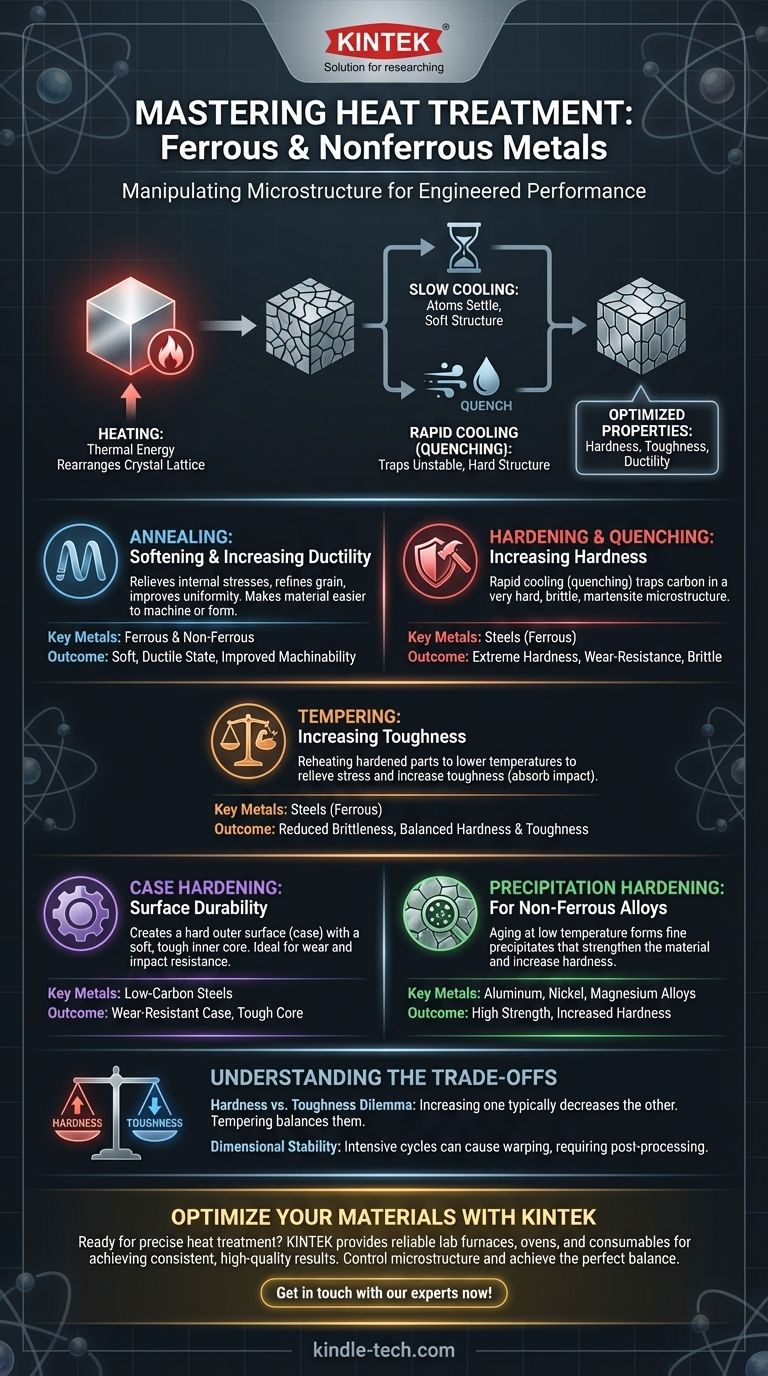

The Goal: Manipulating a Metal's Microstructure

To understand heat treatment, you must first understand that all metals have a crystalline internal structure, often called a microstructure or grain structure. The size, shape, and composition of these microscopic grains determine the metal's properties.

The Role of Temperature

Heating a metal provides thermal energy. This energy allows the atoms within the crystal lattice to move, rearrange, and even dissolve elements into one another, changing the grain structure.

The Critical Role of Cooling Rate

The speed at which a metal is cooled "locks in" a specific microstructure. A slow cool allows atoms time to settle into a soft, stable state. A rapid cool, or quenching, traps them in a highly stressed, unstable, and very hard state.

Key Heat Treatment Processes and Their Purpose

Each process is defined by its unique temperature and cooling profile, designed to achieve a specific outcome. These processes can be broadly categorized by their primary function.

For Softening and Increasing Ductility: Annealing

Annealing is a process used to make a metal as soft and ductile as possible. It involves heating the metal, holding it at that temperature, and then cooling it very slowly.

This slow cool relieves internal stresses, refines the grain structure, and improves uniformity. It is often performed to make a material easier to machine or form, or to undo the effects of work-hardening. Annealing is common for both ferrous and non-ferrous metals.

For Increasing Hardness: Hardening & Quenching

Hardening applies primarily to steels and other ferrous alloys with sufficient carbon content. The steel is heated to a critical temperature where its crystal structure changes, and then cooled rapidly by quenching it in a medium like water, oil, or air.

This rapid cooling traps the carbon in a very hard, brittle, needle-like microstructure called martensite. The resulting part is extremely hard and wear-resistant but too brittle for most applications without a follow-up process.

For Increasing Toughness: Tempering

Tempering is almost always performed after hardening. The hardened, brittle part is reheated to a much lower temperature, held for a specific time, and then cooled.

This process relieves some of the internal stress from quenching and allows the hard martensite structure to transform slightly. The result is a decrease in hardness but a significant and critical increase in toughness, which is the ability to absorb impact without fracturing.

For Surface Durability: Case Hardening

Case hardening creates a part with two distinct zones: an extremely hard, wear-resistant outer surface (the "case") and a softer, tougher inner core. This is ideal for components like gears and bearings that must resist surface wear while also withstanding impact loads.

A common method is carburizing, where a low-carbon steel part is heated in a carbon-rich atmosphere. Carbon diffuses into the surface, allowing only the outer layer to become hardenable during a subsequent quench.

For Non-Ferrous Alloys: Precipitation Hardening

Many non-ferrous alloys, like aluminum, magnesium, and nickel alloys, cannot be hardened by quenching like steel. Instead, they use precipitation hardening (or age hardening).

The process involves heating the alloy to dissolve alloying elements into a solid solution, quenching it to trap this state, and then "aging" it at a lower temperature. This aging allows very fine particles (precipitates) to form within the grain structure, which act as obstacles to deformation and dramatically increase the material's strength and hardness.

Understanding the Trade-offs

Choosing a heat treatment process is always a matter of balancing competing properties. No single process can maximize all desirable traits.

The Hardness vs. Toughness Dilemma

This is the most fundamental trade-off in metallurgy. As you increase a metal's hardness, you almost invariably decrease its toughness, making it more brittle. A fully hardened, un-tempered steel part has maximum hardness but will shatter like glass. Tempering is the act of intentionally sacrificing some hardness to gain essential toughness.

Dimensional Stability and Distortion

The intense heating and rapid cooling cycles, especially quenching, introduce significant internal stresses. These stresses can cause parts to warp, twist, or change dimensions, often requiring secondary grinding or machining operations to meet final tolerances.

Process Complexity and Cost

Simpler processes like annealing are relatively inexpensive. Multi-step processes like case hardening or quench-and-temper cycles require more sophisticated equipment, tighter controls, and longer furnace times, adding significant cost to the final part.

Selecting the Right Process for Your Application

Your choice must be driven by the primary performance requirement of the component.

- If your primary focus is making a metal easier to machine or form: Annealing is your process to create the softest, most ductile state.

- If your primary focus is extreme surface wear on a part that must also absorb impact (e.g., a gear): Case hardening provides the necessary hard case and tough core.

- If your primary focus is a steel component that must hold a sharp edge and resist fracture (e.g., a knife or tool): A quench and temper process is required to balance hardness and toughness.

- If your primary focus is achieving high strength in an aluminum, titanium, or nickel alloy: Precipitation hardening is the standard method for these non-ferrous materials.

Ultimately, heat treatment transforms a generic metal into a high-performance material engineered for a specific task.

Summary Table:

| Process | Primary Goal | Key Metals | Key Outcome |

|---|---|---|---|

| Annealing | Soften, Increase Ductility | Ferrous & Non-Ferrous | Relieves stress, improves machinability |

| Hardening & Quenching | Increase Hardness | Steels (Ferrous) | Creates hard, brittle martensite structure |

| Tempering | Increase Toughness | Steels (Ferrous) | Reduces brittleness after hardening |

| Case Hardening | Create Hard Surface/Tough Core | Low-Carbon Steels | Wear-resistant case (e.g., via carburizing) |

| Precipitation Hardening | Increase Strength/Hardness | Aluminum, Nickel, Magnesium Alloys | Strengthens via fine particle precipitation |

Ready to optimize your materials with precise heat treatment? The right lab equipment is crucial for achieving consistent, high-quality results. KINTEK specializes in providing reliable lab furnaces, ovens, and consumables tailored for annealing, hardening, tempering, and other thermal processes. Whether you're in R&D or quality control, our solutions help you control microstructure and achieve the perfect balance of hardness, toughness, and ductility for your specific metal components.

Contact us today to discuss your application needs and discover how KINTEK can enhance your laboratory's capabilities.

Get in touch with our experts now!

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- Vertical Laboratory Tube Furnace

People Also Ask

- What affects the rate of melting? Master the Key Factors for Precise Control

- What is the use of muffle furnace in pharmaceutical industry? Ensure Drug Purity with Precise High-Temp Analysis

- What temperature is needed for metal casting? Achieve Perfect Casts with the Right Superheat

- Why is the metal melting temperature important? The Key to Manufacturing & Performance

- What controls melting point? The Hierarchy of Forces from Ionic Bonds to Intermolecular Attractions