At its core, a muffle furnace is a self-contained, high-temperature oven designed for precision. Its primary components include an insulated external enclosure, an inner heating chamber (the muffle), heating elements, a temperature sensor and controller, and various safety mechanisms. These parts work together to create an isolated, uniform, and highly controlled heating environment.

The defining characteristic of a muffle furnace is the "muffle" itself—an inner chamber that isolates the material being heated from the direct radiation and combustion byproducts of the heating elements. This separation is the key to achieving a clean, contaminant-free, and uniformly heated result.

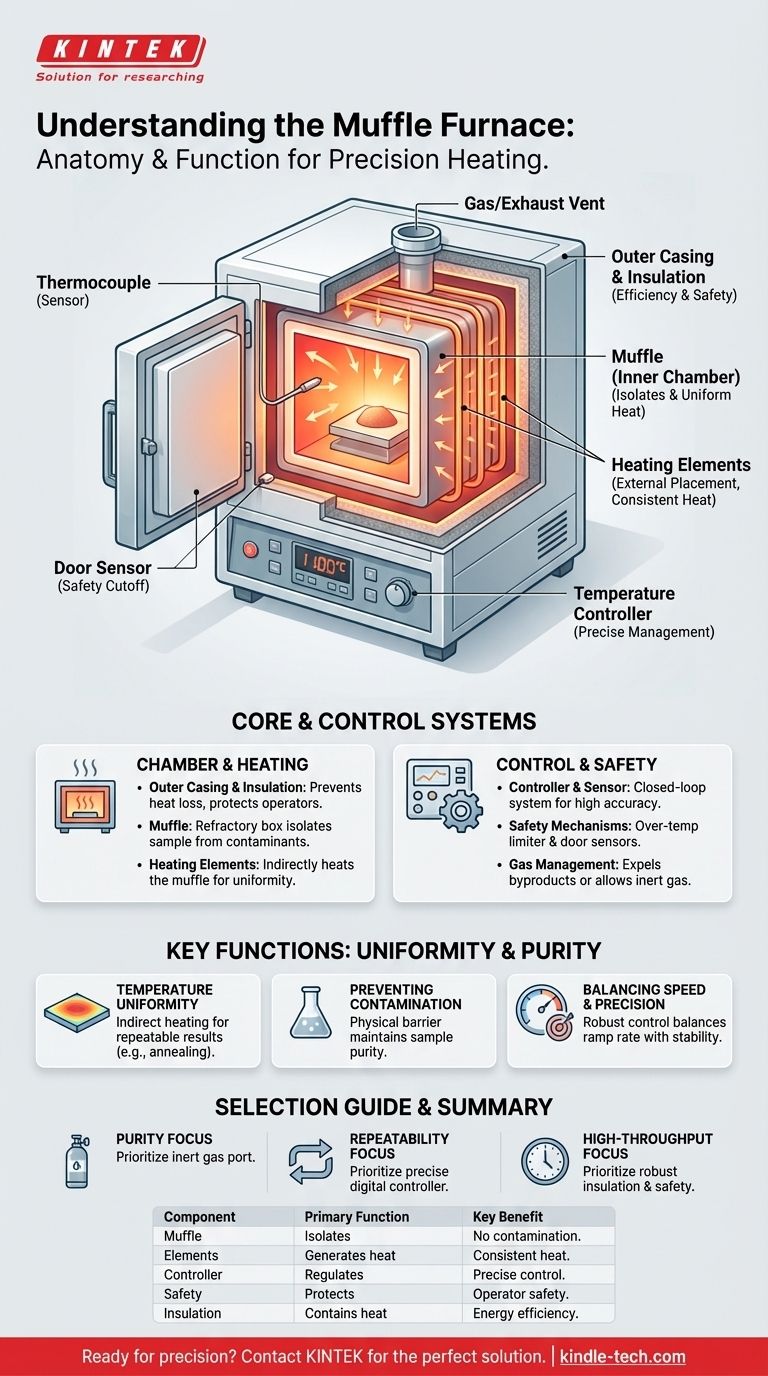

The Core Components: Chamber and Heating System

The fundamental purpose of a muffle furnace is to generate and contain extreme heat. This is accomplished through a synergistic system of insulation, an inner chamber, and carefully placed heating elements.

The Outer Casing and Insulation

The external body of the furnace provides structural support and the first line of defense against heat loss. This enclosure is lined with high-quality insulating materials.

This insulation is critical for both energy efficiency and operator safety, ensuring that the high internal temperatures do not radiate excessively into the lab environment.

The Muffle (Inner Chamber)

This is the heart of the furnace. The muffle is a box-like chamber made from refractory materials, such as a blend of silica and aluminum.

Its design serves two primary functions: it protects the sample from direct contact with the heating elements, preventing contamination, and it distributes heat evenly through a combination of radiant and convection transfer. This ensures the entire workpiece receives a homogeneous thermal treatment.

The Heating Elements

These are responsible for generating the high temperatures required for processes. They are strategically placed around the outside of the muffle chamber.

This arrangement allows the elements to heat the muffle, which in turn radiates heat uniformly into the sample space, avoiding hot spots and uneven processing.

Control and Safety Systems

Reaching high temperatures is only useful if it can be done accurately and safely. The control and safety systems are what elevate a muffle furnace from a simple oven to a precise scientific instrument.

The Temperature Controller and Sensor

The control panel is the user's interface, allowing for precise management of heating cycles. A sensor, typically a thermocouple, is placed inside the chamber to provide real-time temperature feedback.

This closed-loop system allows the controller to maintain a set temperature with high accuracy. Modern furnaces often use solid-state relays to manage power, resulting in low-noise and reliable operation.

Critical Safety Mechanisms

Safety is paramount when dealing with extreme heat. Muffle furnaces incorporate multiple layers of protection to safeguard both the equipment and the load.

These include an over-temperature limiter that automatically cuts power if a set temperature is exceeded, a door sensor that shuts off heating when the door is opened, and audible or visual alarms for system failures.

Gas and Exhaust Management

Many high-temperature processes release gases or require a specific atmosphere. A release hole or vent is included to safely expel these byproducts.

Some models also feature a protective gas connection, which allows users to purge the chamber with a non-flammable gas, like nitrogen or argon, to prevent oxidation or create a controlled, inert atmosphere.

Understanding the Trade-offs and Key Functions

The specific construction of a muffle furnace directly impacts its performance and suitability for different applications. Understanding these design choices is key to leveraging the instrument effectively.

Achieving Temperature Uniformity

The separation between the heating elements and the chamber is a deliberate design choice. While direct heating might be faster, the indirect heating via the muffle is essential for temperature uniformity, which is critical for repeatable and reliable results in material testing, ashing, and annealing.

Preventing Cross-Contamination

The muffle's primary role is isolation. In applications like chemical analysis or materials science, even microscopic contaminants from heating elements can compromise results. The muffle acts as a physical barrier, ensuring the sample's purity is maintained.

Balancing Speed and Precision

Muffle furnaces are designed for rapid heating and cooling cycles. However, the true value lies in their control. The trade-off is often between the maximum ramp rate (how quickly it heats up) and the stability of the temperature once it reaches the setpoint. A robust control system ensures precision is not sacrificed for speed.

How to Apply This to Your Selection

Choosing the right muffle furnace means matching its components and features to your specific laboratory or industrial goals.

- If your primary focus is material purity and analysis: Prioritize a furnace with a high-quality, non-reactive muffle material and a port for introducing inert gases.

- If your primary focus is process repeatability: A precise digital controller with a reliable thermocouple and solid-state relays is the most critical feature for consistent results.

- If your primary focus is high-throughput or frequent use: Look for robust insulation for energy efficiency and comprehensive safety features like door cutoffs and over-temperature protection to ensure safe, continuous operation.

By understanding how each component contributes to the furnace's function, you can confidently select and operate the right instrument for your work.

Summary Table:

| Component | Primary Function | Key Benefit |

|---|---|---|

| Muffle (Inner Chamber) | Isolates samples from heating elements | Prevents contamination, ensures uniform heating |

| Heating Elements | Generates high temperatures | Provides consistent, indirect heat |

| Temperature Controller & Sensor | Monitors and regulates temperature | Enables precise control and repeatability |

| Safety Mechanisms | Protects equipment and operator | Includes over-temperature limiter and door cutoff |

| Outer Casing & Insulation | Contains heat and provides structure | Improves energy efficiency and safety |

Ready to select the perfect muffle furnace for your lab's specific needs?

Understanding the components is the first step. KINTEK specializes in high-quality lab equipment, including muffle furnaces designed for precision, purity, and repeatability. Whether your focus is material analysis, process repeatability, or high-throughput applications, we have the right solution.

Let our experts help you:

- Match the right furnace to your application (e.g., ashing, annealing, heat treatment).

- Ensure optimal performance with features like inert gas inlets and precise digital controllers.

- Enhance your lab's efficiency and safety with reliable equipment from a trusted supplier.

Contact KINTEL today to discuss your requirements and get a personalized recommendation!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the requisites of refractories? The Four Pillars for High-Temperature Success

- What is the yield of biochar in slow pyrolysis? Maximize Your Output Up to 30%

- Do you need to heat the clean crucible before using it? Prevent Thermal Shock and Ensure Process Accuracy

- How does tempering reduce hardness? Achieve the Perfect Balance of Toughness and Durability

- Does casting change material properties? Understand the Microstructural Impact on Performance