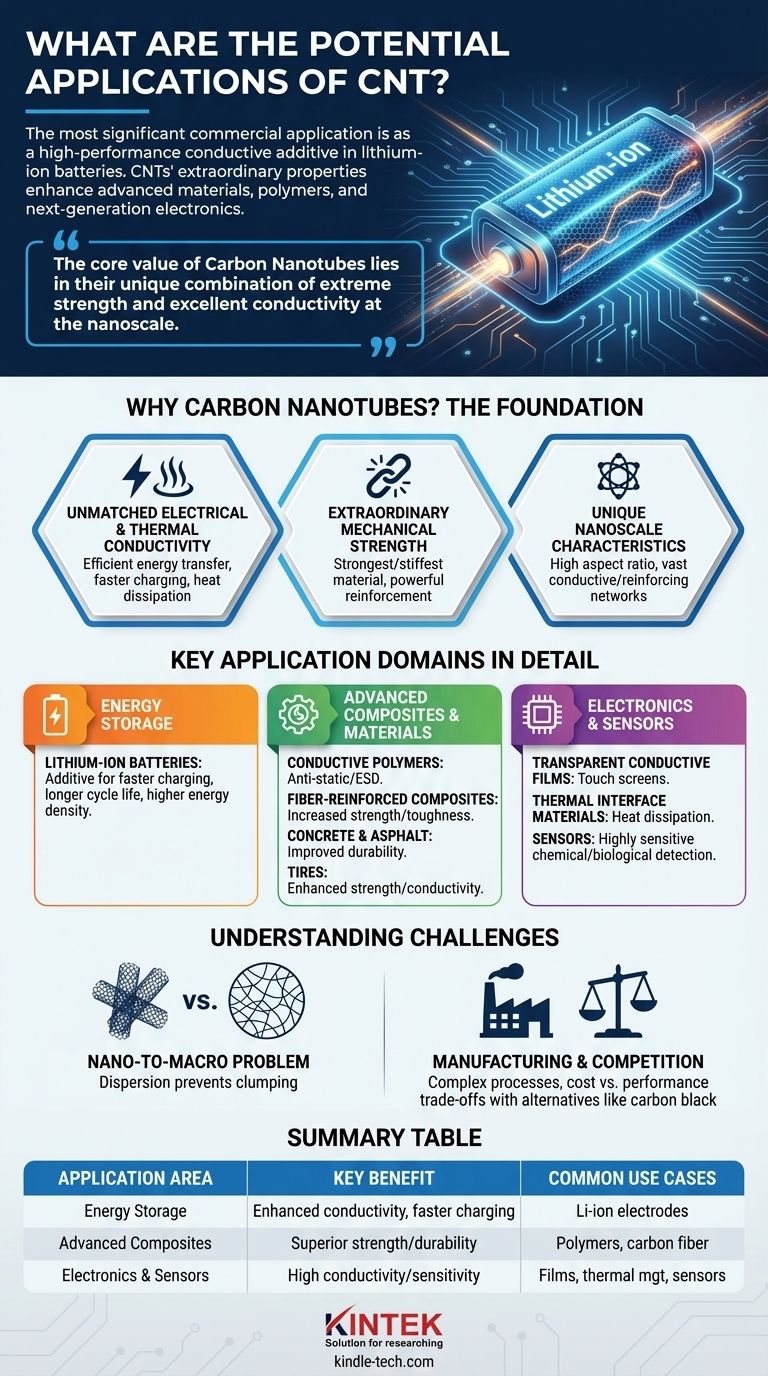

In practice, the most significant commercial application for Carbon Nanotubes (CNTs) today is as a high-performance conductive additive in the cathodes and anodes of lithium-ion batteries. Beyond this primary market, their extraordinary properties are being leveraged to enhance advanced materials, including composites, polymers, and next-generation electronics.

The core value of Carbon Nanotubes lies in their unique combination of extreme strength and excellent conductivity at the nanoscale. However, their widespread adoption depends entirely on overcoming the significant engineering challenge of translating these nanoscale properties into cost-effective, macro-scale products.

Why Carbon Nanotubes? The Foundation of Their Potential

To understand the applications of CNTs, you must first understand the fundamental properties that make them so compelling. Their value proposition is not based on a single characteristic, but on the powerful combination of several.

Unmatched Electrical & Thermal Conductivity

CNTs are exceptional conductors of electricity and heat. This makes them ideal for applications where efficient energy transfer is critical, such as improving the charge rate and longevity of batteries or dissipating heat in sensitive electronics.

Extraordinary Mechanical Strength

On a pound-for-pound basis, CNTs are one of the strongest and stiffest materials ever discovered. This phenomenal strength allows them to act as a powerful reinforcement agent, dramatically improving the durability and resilience of composite materials even when added in very small quantities.

Unique Nanoscale Characteristics

The long, thin, cylindrical shape of CNTs gives them a very high aspect ratio. This structure is key to their effectiveness, allowing them to create vast conductive and reinforcing networks throughout a host material, such as a polymer or concrete matrix.

Key Application Domains in Detail

While research explores countless possibilities, the practical application of CNTs is currently concentrated in areas where their unique benefits justify their cost and technical complexity.

Energy Storage: The Primary Market Driver

The most mature market for CNTs is in lithium-ion batteries. They are used as a conductive additive to improve electrode performance, enabling faster charging, longer cycle life, and higher energy density. This is a direct replacement and upgrade for more traditional additives like carbon black.

Advanced Composites & Materials

CNTs are used as additives to create a new class of high-performance materials.

- Conductive Polymers: Adding CNTs makes plastics electrically conductive, useful for anti-static and electrostatic discharge (ESD) applications in electronics packaging or fuel lines.

- Fiber-Reinforced Composites: Incorporating CNTs into carbon fiber or fiberglass composites can increase strength and fracture toughness.

- Concrete & Asphalt: Early-stage applications show that CNTs can improve the mechanical properties and durability of infrastructure materials.

- Tires: Used in small amounts, CNTs can enhance the strength, durability, and conductive properties of rubber.

Electronics & Sensors

The unique electrical properties of CNTs make them a candidate for next-generation electronics.

- Transparent Conductive Films: CNTs can create films that are both electrically conductive and optically transparent, a key requirement for touch screens and flexible displays.

- Thermal Interface Materials: Their high thermal conductivity helps dissipate damaging heat from microprocessors and other electronic components.

- Sensors: The extreme sensitivity of CNTs' electrical properties to their surrounding environment makes them ideal for building highly sensitive chemical and biological sensors.

Understanding the Trade-offs and Challenges

Trust in any material technology requires an objective look at its limitations. The path from the lab to a finished product is not straightforward for Carbon Nanotubes.

The Nano-to-Macro Problem

The incredible properties of a single nanotube are often lost when they are aggregated into a macro-scale product like a sheet or yarn. The primary challenge is dispersion—preventing the nanotubes from clumping together, which severely degrades their performance.

Manufacturing and Purification Hurdles

Producing high-quality CNTs with consistent properties and high purity remains a complex manufacturing process. Techniques like functionalization, which modifies the surface of the CNT to improve bonding with a host material, add further complexity and cost.

The Competitive Landscape

CNTs do not exist in a vacuum. They compete directly with other conductive carbon additives like carbon black, chopped carbon fiber, and graphene. The final choice often comes down to a trade-off between the level of performance required and the cost that an application can bear.

Making the Right Choice for Your Goal

The decision to use CNTs must be driven by a clear technical or performance objective.

- If your primary focus is maximum electrical or thermal performance: CNTs are a leading candidate, especially in applications like batteries or thermal interfaces where alternatives fall short.

- If your primary focus is adding strength to a composite material: CNTs offer a high-performance solution, but you must invest in solving the dispersion and integration challenges to realize their full potential.

- If your primary focus is cost-sensitive conductivity: Carefully evaluate if cheaper, more established alternatives like carbon black or chopped carbon fiber can meet your requirements before committing to the higher cost of CNTs.

Ultimately, the successful application of Carbon Nanotubes is a story of advanced engineering, where their profound potential is unlocked only by mastering the complexities of their integration.

Summary Table:

| Application Area | Key Benefit of CNTs | Common Use Cases |

|---|---|---|

| Energy Storage | Enhanced conductivity for faster charging & longer life | Lithium-ion battery electrodes |

| Advanced Composites | Superior strength & durability reinforcement | Conductive polymers, carbon fiber composites |

| Electronics & Sensors | High electrical/thermal conductivity & sensitivity | Transparent films, thermal management, chemical sensors |

Ready to enhance your materials with the power of Carbon Nanotubes?

At KINTEK, we specialize in providing high-quality lab equipment and consumables to support your advanced material development. Whether you are researching battery technologies, developing stronger composites, or creating next-generation electronics, our solutions are designed to meet the precise demands of your laboratory.

Let us help you unlock the full potential of CNTs in your projects. Contact our experts today to discuss your specific needs and discover how KINTEK can support your innovation journey.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Multi-zone Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating