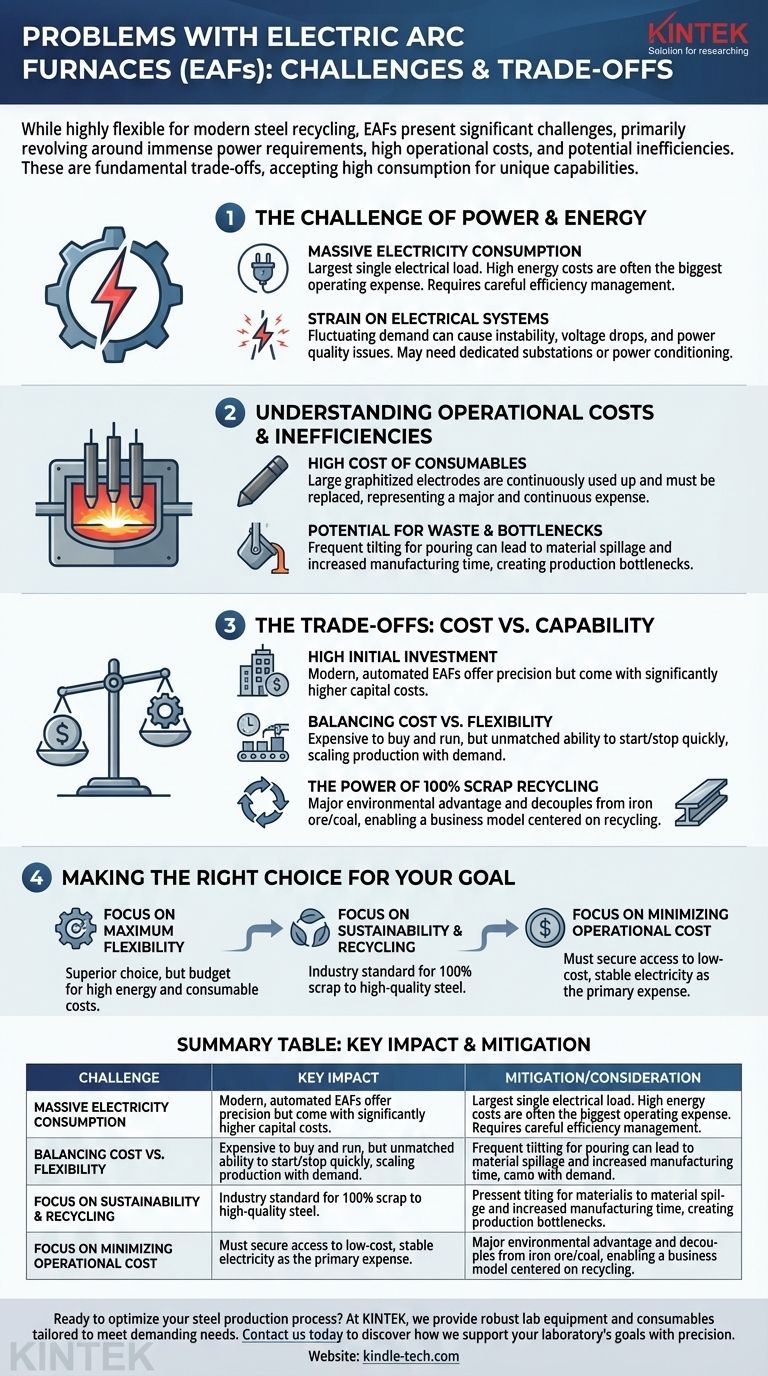

While highly flexible and essential for modern steel recycling, Electric Arc Furnaces (EAFs) present significant challenges, primarily revolving around their immense power requirements, high operational costs, and potential process inefficiencies. These issues are not necessarily deal-breakers but are critical factors that must be managed to operate an EAF effectively and profitably.

The core problems of an Electric Arc Furnace are not inherent design flaws but rather fundamental trade-offs. A facility accepts high energy consumption and operational costs in exchange for unparalleled production flexibility and the unique ability to use 100% scrap metal feedstock.

The Challenge of Power and Energy

The defining characteristic of an EAF is its reliance on a massive electrical arc to melt steel. This dependency is the source of its most significant operational challenges.

Massive Electricity Consumption

An EAF is one of the largest single electrical loads that can be placed on a power grid. This significant power draw translates directly into very high energy costs, which is often the largest component of the furnace's operating budget. Careful management and efficiency monitoring are not optional; they are essential for financial viability.

Strain on Electrical Systems

The immense and fluctuating power demand can cause instability in the local electrical grid. This can lead to issues like voltage drops and power quality disturbances (flicker) that affect other users on the same network. Consequently, EAF installations often require dedicated substations or expensive power conditioning equipment to mitigate these effects.

Understanding Operational Costs and Inefficiencies

Beyond the cost of electricity, the day-to-day operation of an EAF involves other significant expenses and potential bottlenecks.

High Cost of Consumables

The process relies on large graphitized electrodes to create the electric arc. These electrodes are consumables—they are gradually used up during the melting process and must be replaced regularly. The cost of these high-grade electrodes is a major and continuous operational expense.

Potential for Material and Time Wastage

The physical operation of some furnaces can introduce inefficiencies. For processes that require frequent tilting to pour molten metal into individual molds, there can be material wastage from spillage and increased manufacturing time. This cycle of tilting and changing molds can become a bottleneck in high-throughput environments.

The Trade-offs: Cost vs. Capability

The problems associated with EAFs must be weighed against their unique and powerful advantages. No decision can be made without understanding this balance.

High Initial Investment

Modern, highly automated EAFs with pre-programmed cycles for different steel grades offer incredible precision and efficiency. However, this complexity and advanced functionality come at a price, making the initial capital investment significantly higher than for simpler furnace models.

Balancing Cost Against Unmatched Flexibility

This is the central trade-off. While expensive to buy and run, an EAF's flexibility is unmatched. Unlike traditional furnaces, an EAF can be started and stopped relatively quickly, allowing production to scale with demand. This makes it ideal for specialized "mini-mills."

The Power of 100% Scrap Recycling

Perhaps the most important benefit is the EAF's ability to operate using 100% recycled steel scrap. This not only provides a massive environmental advantage but also allows producers to decouple from the raw material supply chain of iron ore and coal, creating a distinct business model centered on recycling.

Making the Right Choice for Your Goal

To determine if an EAF is appropriate, you must align its characteristics with your primary strategic objective.

- If your primary focus is maximum production flexibility: The EAF is the superior choice, but you must budget for high energy consumption and the cost of consumable electrodes.

- If your primary focus is environmental sustainability and recycling: The EAF is the industry standard for turning 100% scrap metal into new, high-quality steel products.

- If your primary focus is minimizing operational cost: You must secure access to a source of low-cost, stable electricity, as this will be your largest ongoing expense.

Understanding these challenges is the first step toward leveraging the unique strategic advantages of electric arc furnace technology.

Summary Table:

| Challenge | Key Impact | Mitigation/Consideration |

|---|---|---|

| Massive Electricity Consumption | High energy costs, largest operational expense | Requires careful efficiency monitoring and management |

| Strain on Electrical Grid | Voltage drops, power quality issues | Often needs dedicated substations or power conditioning equipment |

| High Cost of Consumables | Graphite electrodes are a major recurring expense | Budgeting for regular replacement is essential |

| Potential for Inefficiencies | Material wastage, time bottlenecks in tilting/mold changes | Optimized operational procedures can reduce losses |

| High Initial Investment | Significant capital cost for advanced, automated systems | Higher upfront cost for long-term flexibility and precision |

Ready to optimize your steel production process? At KINTEK, we specialize in providing robust lab equipment and consumables tailored to meet the demanding needs of modern laboratories. Whether you're researching furnace efficiency, testing materials, or developing new steel grades, our solutions help you manage operational challenges effectively. Contact us today to discover how KINTEK can support your laboratory's goals with precision and reliability.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- How do you clean a quartz tube furnace? Prevent Contamination & Extend Tube Lifespan

- What temperature is tube annealing? A Guide to Material-Specific Ranges for Optimal Results

- What is the process of annealing tubes? Achieve Optimal Softness and Ductility for Your Tubing

- Why does heating increase temperature? Understanding the Molecular Dance of Energy Transfer

- What is a vertical tube furnace? Leverage Gravity for Superior Uniformity and Process Control