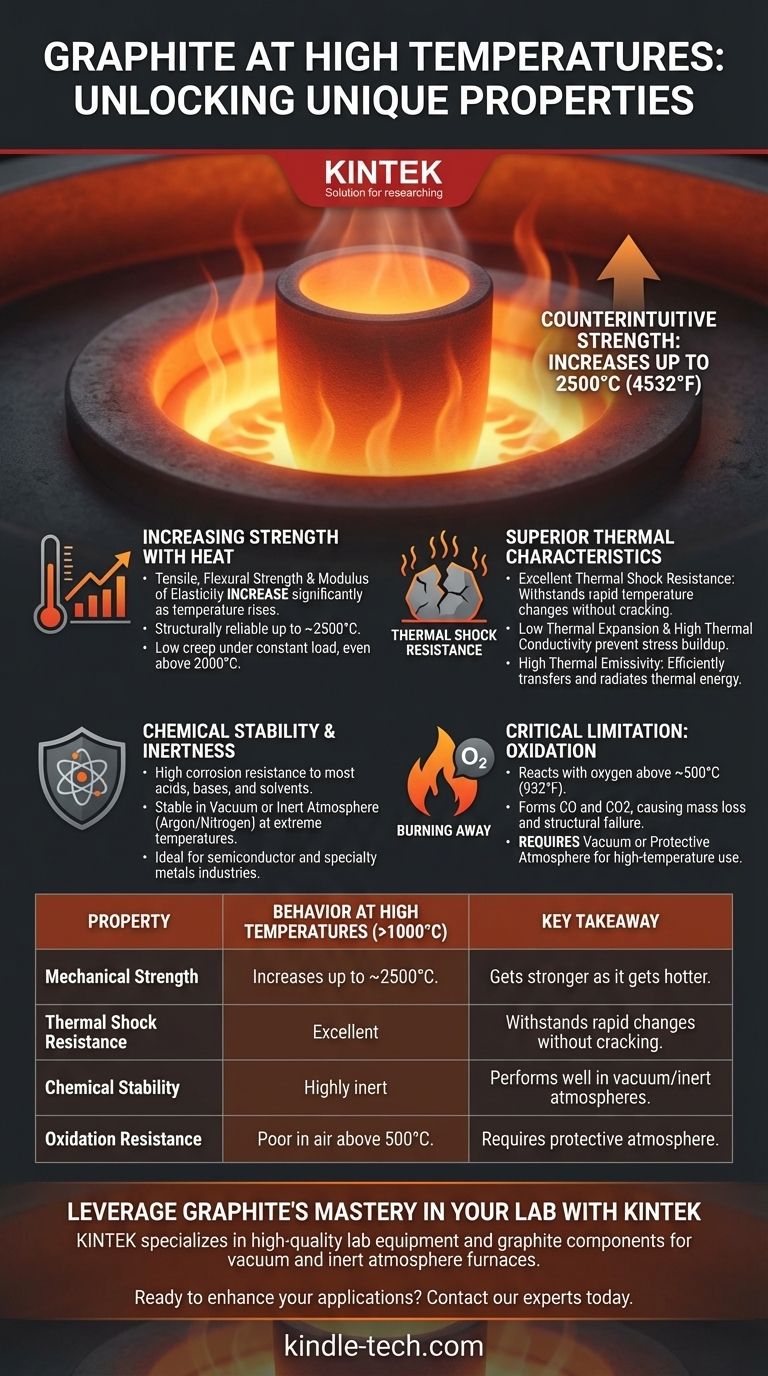

At high temperatures, graphite exhibits a unique and highly valuable set of properties. Unlike most materials that weaken, graphite's mechanical strength actually increases with temperature up to around 2500°C (4532°F). This, combined with its excellent resistance to thermal shock and chemical corrosion, makes it a premier material for extreme heat environments.

The central takeaway is that graphite's performance improves in extreme heat, making it an exceptional choice for high-temperature applications. However, this advantage is entirely dependent on controlling its primary vulnerability: oxidation in the presence of air.

The Counterintuitive Strength of Graphite

Increasing Strength with Heat

Graphite's most remarkable high-temperature property is its relationship between strength and heat. As temperature rises, its tensile strength, flexural strength, and modulus of elasticity all increase significantly.

This behavior continues up to approximately 2500°C, after which its strength begins to decline as it approaches its sublimation point around 3600°C. This makes it structurally reliable in applications where other materials would fail.

Low Creep Under Load

Creep is the tendency of a material to deform permanently under a constant load at high temperatures. Graphite exhibits very low creep, even at temperatures exceeding 2000°C, ensuring dimensional stability in structural components like furnace fixtures.

Superior Thermal Characteristics

Exceptional Thermal Shock Resistance

Graphite can withstand rapid and extreme temperature changes without cracking or failing. This resistance to thermal shock is a direct result of two core properties working together.

First, it has a very low coefficient of thermal expansion, meaning it doesn't expand or contract much when its temperature changes. Second, it has high thermal conductivity, allowing it to dissipate heat quickly and evenly, preventing localized stress buildup.

High Thermal Emissivity

Graphite is an excellent radiator of thermal energy, a property known as high emissivity. This allows it to efficiently transfer heat, which is a critical function for components like heating elements and heat shields in vacuum furnaces.

Chemical Stability and Inertness

High Corrosion Resistance

As noted in many industrial applications, graphite is chemically inert and highly resistant to corrosion from most acids, bases, and solvents. This stability is maintained and often enhanced at elevated temperatures.

Performance in Different Atmospheres

In a vacuum or an inert atmosphere (like argon or nitrogen), graphite remains stable at extremely high temperatures. This is why it is the dominant material for hot-zone components in vacuum and inert gas furnaces.

Understanding the Critical Limitation: Oxidation

The Reaction with Oxygen

Graphite's primary weakness at high temperatures is its reaction with oxygen. In the presence of air or other oxidizing gases, graphite will begin to oxidize at temperatures starting around 500°C (932°F).

This reaction forms carbon monoxide (CO) and carbon dioxide (CO2) gas, essentially causing the material to burn away and lose mass and structural integrity. The rate of oxidation increases dramatically with temperature.

The Need for a Controlled Environment

Because of this vulnerability, graphite is almost exclusively used for high-temperature applications inside a vacuum or a protective, non-oxidizing atmosphere. If it must be used in air, it can only be for short durations or with specialized anti-oxidation coatings.

Making the Right Choice for Your Application

- If your primary focus is structural integrity under extreme heat: Graphite's unique ability to get stronger as it gets hotter makes it the ideal choice for furnace shelving, fixtures, and structural elements.

- If your primary focus is surviving rapid heating and cooling cycles: Graphite's unparalleled thermal shock resistance ensures longevity for components like crucibles and casting molds.

- If your primary focus is chemical purity and non-reactivity: Its inertness makes graphite perfect for applications in the semiconductor and specialty metals industries.

- If you must operate in an open-air environment above 500°C: Standard graphite is unsuitable, and you must consider either graphite with a protective coating or a different class of material, like a ceramic composite.

Ultimately, graphite's mastery over high-temperature environments is secured as long as its one major vulnerability—oxygen—is properly managed.

Summary Table:

| Property | Behavior at High Temperatures (>1000°C) | Key Takeaway |

|---|---|---|

| Mechanical Strength | Increases up to ~2500°C | Gets stronger as it gets hotter. |

| Thermal Shock Resistance | Excellent | Withstands rapid temperature changes without cracking. |

| Chemical Stability | Highly inert and corrosion-resistant | Performs well in vacuum or inert atmospheres. |

| Oxidation Resistance | Poor in air above 500°C | Requires a protective atmosphere to prevent burning. |

Leverage Graphite's High-Temperature Mastery in Your Lab

Graphite's unique properties make it indispensable for high-temperature processes, but its performance hinges on using the right equipment and consumables. KINTEK specializes in high-quality lab equipment, including graphite components designed for vacuum and inert atmosphere furnaces, ensuring your materials perform reliably under extreme conditions.

Ready to enhance your high-temperature applications? Contact our experts today to discuss your specific needs and discover how our solutions can drive your success.

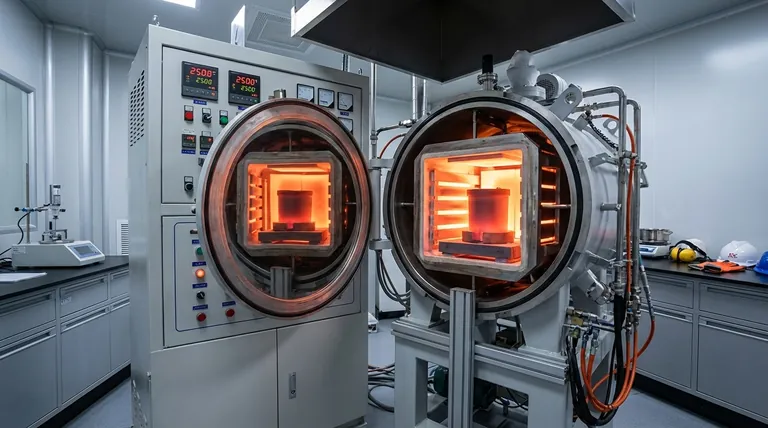

Visual Guide

Related Products

- Graphite Vacuum Continuous Graphitization Furnace

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Why is platinum (Pt) foil utilized as a reference material? Safeguard Purity in Supercritical Water Experiments

- What are the necessary pre-treatment steps for a platinum disk electrode before an experiment? Achieve Reliable Electrochemical Data

- Which electrode is used as a ground reference? Master the Key to Accurate Electrochemical Measurements

- What are the examples of electrode materials? From Platinum to Graphite for Your Application

- Why are Ruthenium-Titanium MMO electrodes preferred for chlorate production? Optimize Efficiency & Durability

- What are the characteristics of a mercuric oxide electrode for alkaline solutions? Achieve Stable Measurements in High pH Environments

- Why is platinum foil selected as the counter electrode (CE) during electrochemical corrosion testing of TiSiCN coatings?

- What maintenance is required for the electrodes used with an all-PTFE electrolytic cell? Expert Care Guide