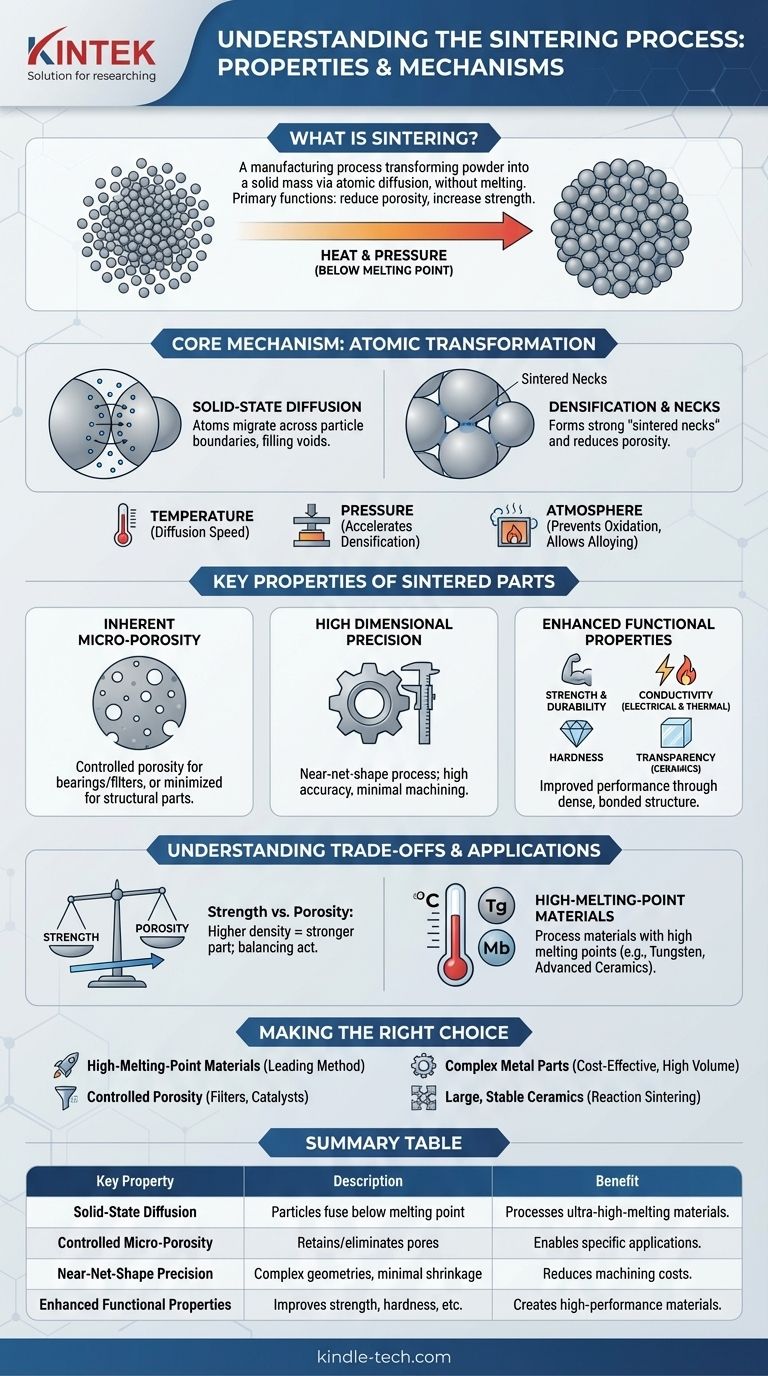

At its core, sintering is a manufacturing process that transforms a powder compact into a dense, solid mass. It achieves this by applying heat and sometimes pressure at a temperature below the material's melting point, causing the individual particles to fuse together through atomic diffusion. This process is fundamental in powder metallurgy and the production of advanced ceramics.

Sintering's primary function is to reduce porosity and dramatically increase a material's strength and other functional properties. The key is that it achieves this transformation without melting the material, making it uniquely suited for creating strong, high-precision components from materials with extremely high melting points.

The Core Mechanism: How Sintering Transforms Materials

Sintering is not a simple heating process; it's a controlled atomic-level transformation. Understanding its mechanism is key to appreciating its capabilities.

The Driving Force: Diffusion, Not Melting

The defining property of sintering is that it works through solid-state diffusion. Instead of liquefying the material, the applied thermal energy makes the atoms within the powder particles highly mobile.

These atoms migrate across the boundaries where particles touch, gradually filling the voids between them and creating strong metallurgical bonds.

The Result: Densification and "Necks"

This atomic movement results in two critical outcomes. First, the gaps and pores between particles are reduced or eliminated, a process known as densification.

Second, where the particles fuse, they form "sintered necks." These necks are the foundation of the final part's strength and structural integrity, turning a loose powder compact into a single, solid piece.

Key Inputs: Temperature, Pressure, and Atmosphere

The sintering process is controlled by several key parameters. Temperature is the primary driver of diffusion speed, while applied pressure can accelerate densification.

The atmosphere within the furnace is also critical, as it can be used to prevent oxidation or even to introduce other elements (like carbon) into the material to form specific alloys.

Key Properties of the Sintered Part

The process directly dictates the final characteristics of the component. A sintered part is not simply a melted and solidified object; it has a unique set of properties.

Inherent Micro-Porosity

Unless a part is sintered to full theoretical density, it will retain a certain level of micro-porosity. The amount and nature of this porosity are often controllable.

This can be a significant advantage for applications like self-lubricating bearings or filters, where porosity is a required feature. For structural components, minimizing porosity is the primary goal.

High Dimensional Precision

Sintering is a near-net-shape process. This means parts can be produced with high dimensional accuracy and complex geometries, often requiring little to no subsequent machining.

Some variants, such as reaction sintering, are noted for having very low shrinkage, making them ideal for large and intricate structures where maintaining dimensional stability is paramount.

Enhanced Functional Properties

The primary reason for sintering is to improve a material's performance. By reducing porosity and creating a dense, bonded structure, the process significantly enhances properties like:

- Mechanical Strength and Durability

- Electrical and Thermal Conductivity

- Hardness

- Transparency (in certain ceramics)

Understanding the Trade-offs

Like any manufacturing process, sintering involves balancing competing factors to achieve the desired outcome. Understanding these trade-offs is essential for successful application.

Strength vs. Porosity

There is a direct inverse relationship between a part's porosity and its mechanical strength. Higher density almost always leads to a stronger part.

However, achieving 100% density can be difficult and costly. The key is to reach a level of densification that meets the component's specific performance requirements without over-engineering the process.

Processing High-Melting-Point Materials

Sintering's ability to operate below the melting point is its greatest strength. It is one of the few viable methods for processing materials like tungsten, molybdenum, and advanced ceramics, whose melting points are too high for conventional casting.

The trade-off is that these materials often require very high sintering temperatures and carefully controlled atmospheres, which can increase process complexity and cost.

Process Control is Paramount

The final properties of a sintered part are extremely sensitive to the initial powder characteristics (e.g., particle size and shape) and the process parameters (temperature, time, pressure).

Achieving consistent, reliable results requires a deep understanding of material science and rigorous process control. This is not a "set and forget" process; it is a highly engineered technical procedure.

Making the Right Choice for Your Goal

Sintering should be chosen when its unique properties align with your design and material requirements.

- If your primary focus is processing high-melting-point materials: Sintering is a leading, and often the only, viable manufacturing method.

- If your primary focus is cost-effective production of complex metal parts: Powder metallurgy using sintering provides an excellent path to creating strong, near-net-shape components at high volume.

- If your primary focus is creating parts with controlled porosity: Sintering offers unique control over a material's internal structure, essential for filters, catalysts, and self-lubricating bearings.

- If your primary focus is manufacturing large, dimensionally stable ceramic structures: A variant like reaction sintering is specifically designed to minimize shrinkage and produce highly dense, complex shapes.

Ultimately, sintering is a powerful and versatile tool that allows engineers to create materials with tailored properties that are often unachievable through other means.

Summary Table:

| Key Property | Description | Benefit |

|---|---|---|

| Solid-State Diffusion | Particles fuse via atomic movement below melting point. | Processes ultra-high-melting-point materials (e.g., tungsten, ceramics). |

| Controlled Micro-Porosity | Retains or eliminates internal pores based on application needs. | Enables self-lubricating bearings, filters, or high-strength structural parts. |

| Near-Net-Shape Precision | Produces complex geometries with minimal shrinkage. | Reduces machining needs and cost for intricate components. |

| Enhanced Functional Properties | Significantly improves strength, hardness, and conductivity. | Creates high-performance materials tailored for specific applications. |

Ready to leverage sintering for your high-performance components? KINTEK specializes in precision lab furnaces and consumables for advanced sintering processes. Whether you're developing ceramics, metal alloys, or specialized filters, our equipment ensures the precise temperature control and atmosphere management critical for success. Contact our experts today to discuss how we can support your laboratory's sintering needs and help you achieve superior material properties.

Visual Guide

Related Products

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Spark Plasma Sintering Furnace SPS Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Are single stage furnaces more reliable? Discover the truth about HVAC durability vs. comfort.

- Does sintering increase conductivity? Yes, by transforming powders into dense, conductive solids.

- What are the factors that affect sample size? Optimize Your Study's Power and Precision

- What are the two structures of molds? Understanding Hyphae and Mycelium

- What are the barriers to plastic recycling? The Economic, Material, and Technical Hurdles Explained

- How does the sputtering process work? A Guide to Thin Film Deposition

- How does a high-speed homogenizer prepare m-BN and PNF dispersions? Achieve Uniform Molecular-Level Integration

- How much sample is needed for XRF? Focus on Quality, Not Quantity, for Accurate Results