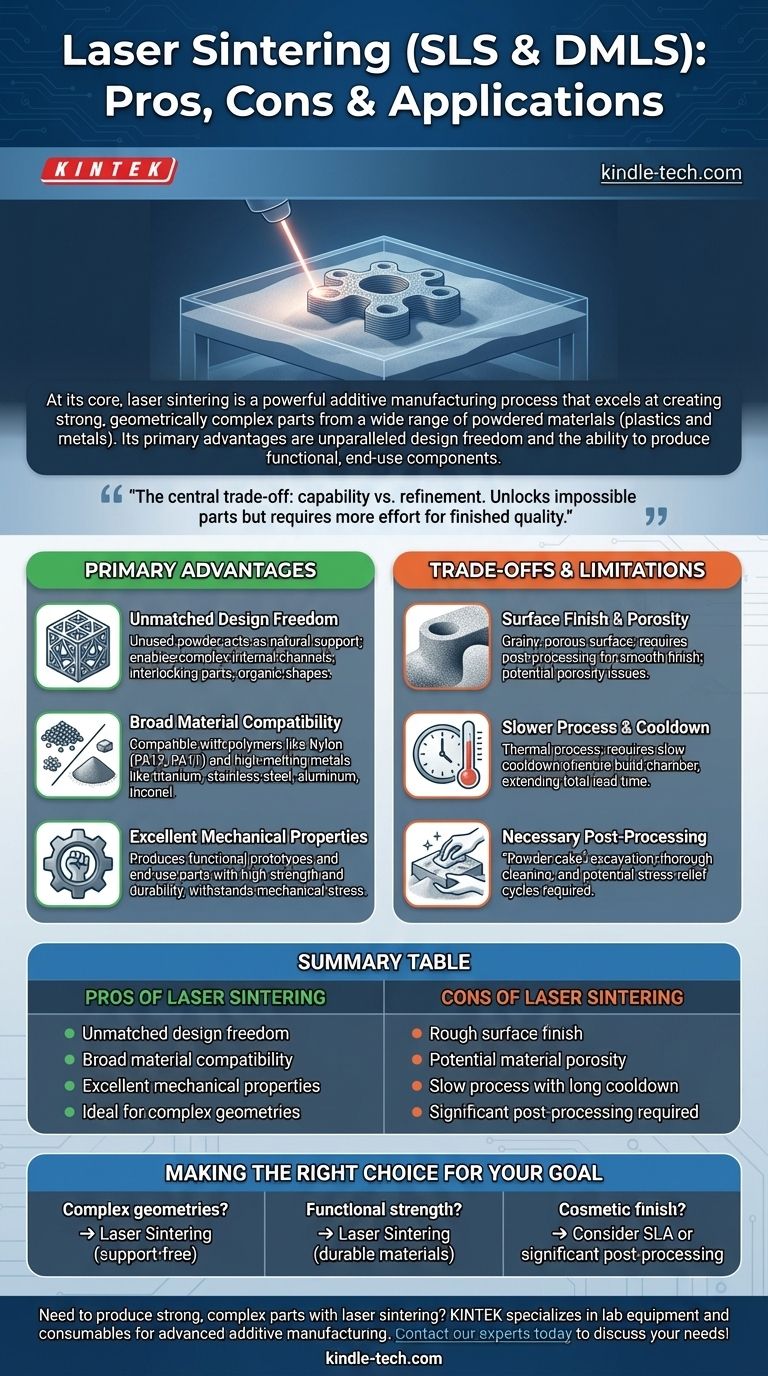

At its core, laser sintering is a powerful additive manufacturing process that excels at creating strong, geometrically complex parts from a wide range of powdered materials, including both plastics and metals. Its primary advantages are unparalleled design freedom and the ability to produce functional, end-use components. However, these benefits are balanced by drawbacks such as a rougher surface finish, potential material porosity, and the need for significant post-processing.

The central trade-off of laser sintering is capability versus refinement. It unlocks the ability to produce parts that are impossible to create with traditional methods, but achieving a finished-quality state often requires more effort than other printing technologies.

The Primary Advantages of Laser Sintering

Laser sintering, often known by the specific process names Selective Laser Sintering (SLS) for polymers and Direct Metal Laser Sintering (DMLS) for metals, offers unique benefits that make it a cornerstone of modern manufacturing.

Unmatched Design Freedom

The single greatest advantage of this technology is that the unused powder in the build chamber acts as a natural support structure for the part being printed.

This self-supporting nature eliminates the need for dedicated support structures that must be manually removed later. This allows for the creation of incredibly complex internal channels, interlocking or moving components printed in a single piece, and organic shapes that would be impossible to machine or mold.

Broad Material Compatibility

The process uses a high-powered laser to fuse powdered materials, making it compatible with a vast array of engineering-grade materials.

This includes durable polymers like Nylon (PA12, PA11) and metals with high melting points like titanium, stainless steel, aluminum, and Inconel. This versatility makes it suitable for demanding industries such as aerospace, medical, and automotive.

Excellent Mechanical Properties

Parts produced via laser sintering are known for their strength and durability, often rivaling or exceeding the properties of parts made through traditional manufacturing.

This makes the technology ideal for producing functional prototypes and end-use parts, not just visual models. These components can withstand significant mechanical stress and environmental exposure.

Understanding the Trade-offs and Limitations

While powerful, laser sintering is not a universal solution. Its unique process introduces specific challenges that must be considered.

Surface Finish and Porosity

The nature of fusing powder granules layer by layer results in a characteristically grainy and porous surface finish.

Parts come out of the machine with a matte, rough texture. While this is suitable for many functional applications, achieving a smooth surface requires post-processing steps like media tumbling, bead blasting, or chemical smoothing. The inherent porosity can also be a concern for applications requiring air-tightness or specific fatigue properties.

Slower Process and Cooldown Times

Laser sintering is a thermal process. After the printing is complete, the entire build chamber full of powder must cool down slowly and evenly to prevent part warping.

This cooldown period can take many hours, sometimes as long as the print job itself. This extends the total lead time compared to technologies where parts are immediately accessible after printing.

Necessary Post-Processing

The workflow does not end when the printer stops. The "powder cake" must be carefully excavated to retrieve the parts.

These parts then need to be thoroughly cleaned to remove all residual powder, a process often done with compressed air or bead blasting. For metal parts, further thermal stress-relief cycles may be required to ensure material stability.

Making the Right Choice for Your Goal

To determine if laser sintering is the right technology, consider your project's primary objective.

- If your primary focus is complex geometries or consolidated assemblies: Laser sintering's support-free nature makes it the ideal choice for parts that are impossible to machine or mold.

- If your primary focus is functional strength in engineering-grade materials: This process excels at creating durable end-use parts from a wide range of polymers and metals for demanding applications.

- If your primary focus is a cosmetic, smooth surface finish directly from the machine: You should consider alternative technologies like Stereolithography (SLA) or plan for significant post-processing steps.

Understanding these core principles allows you to leverage laser sintering not just as a manufacturing tool, but as a strategic engineering advantage.

Summary Table:

| Pros of Laser Sintering | Cons of Laser Sintering |

|---|---|

| Unmatched design freedom (no support structures needed) | Rough, grainy surface finish |

| Broad material compatibility (plastics & metals) | Potential material porosity |

| Excellent mechanical properties for end-use parts | Slow process with long cooldown times |

| Ideal for complex geometries and consolidated assemblies | Significant post-processing required |

Need to produce strong, complex parts with laser sintering? KINTEK specializes in providing the lab equipment and consumables essential for advanced additive manufacturing processes. Whether you're prototyping or producing end-use components, our solutions help you achieve precision and reliability. Contact our experts today to discuss how we can support your laboratory's specific needs!

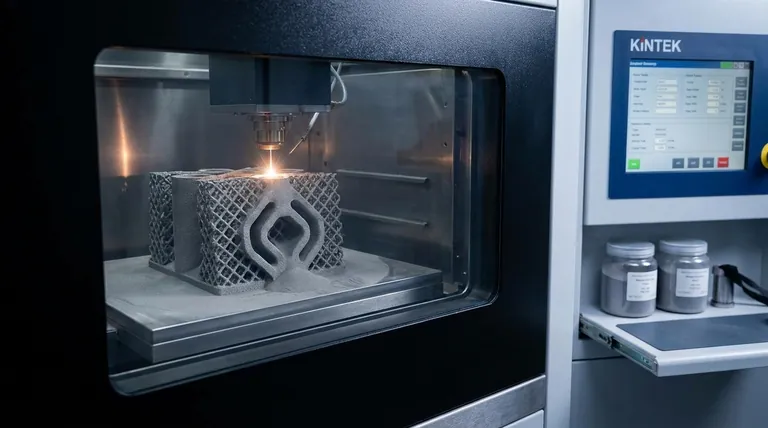

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

People Also Ask

- What critical environmental conditions does a laboratory autoclave provide for evaluating wear resistance? - KINTEK

- What is the necessity of using an autoclave for pre-treating culture media? Ensure Accurate Ag2O/TiO2 Testing

- What is the function of laboratory autoclaves in SCWR research? Predict Material Compatibility and Corrosion Kinetics

- What are the advantages of using an autoclave equipped with a stirring device for molten salt testing? Dynamic Accuracy

- What is the primary function and principle of autoclaving? Master Lab Sterilization with High-Pressure Steam