Fundamentally, safe brazing requires a systematic approach to managing three core hazards: the intense heat of the process, the hazardous fumes generated from heated metals and flux, and direct chemical exposure. While the process involves precise temperature control to melt a filler metal and join components, personal safety is entirely dependent on controlling the work environment and using the correct protective equipment.

Your primary goal in brazing safety is not just to prevent burns, but to control the invisible hazard of airborne contaminants. The single most critical safety measure is ensuring adequate ventilation to remove harmful fumes at their source.

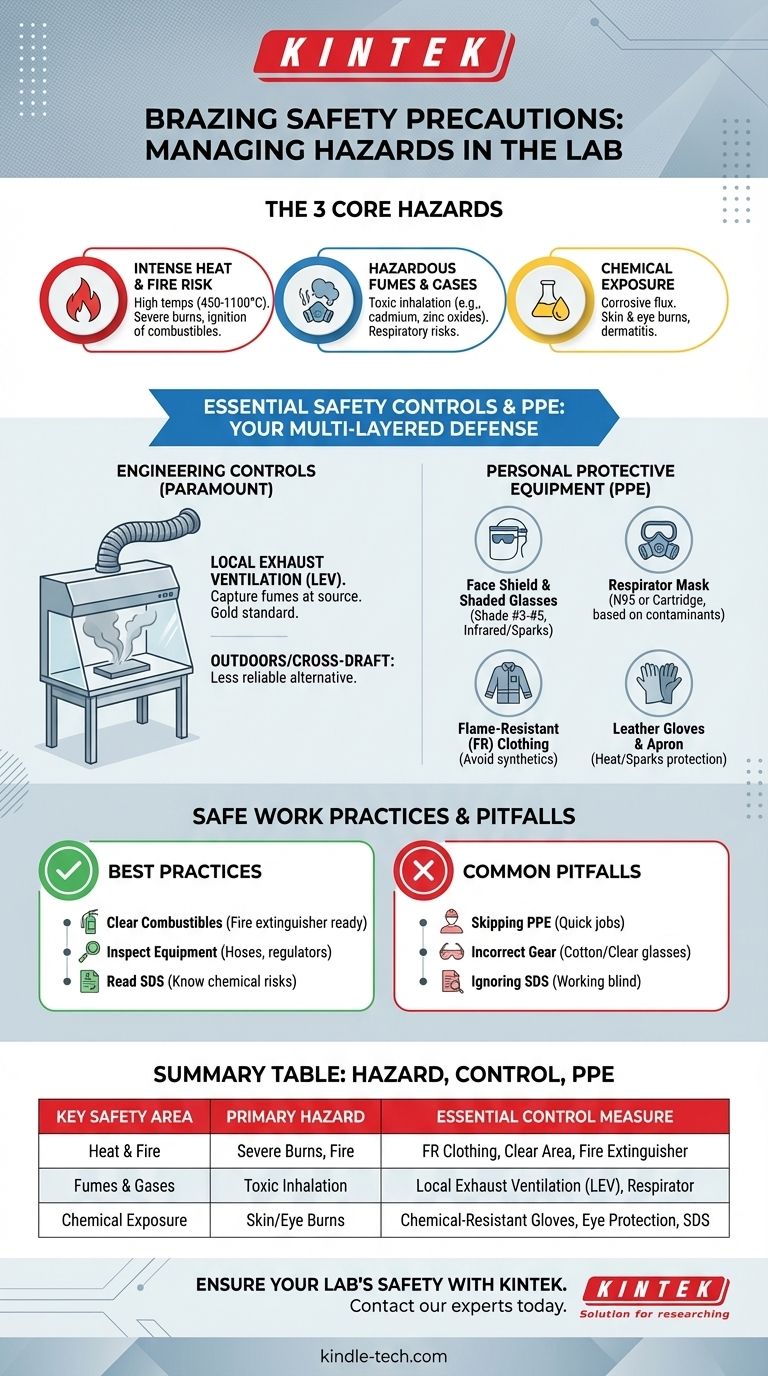

The Primary Hazards of Brazing

Understanding the specific risks is the first step toward mitigating them. Brazing introduces thermal, chemical, and respiratory hazards that must be actively managed.

Intense Heat and Fire Risk

Brazing requires temperatures high enough to melt filler metal, typically ranging from 450°C to over 1100°C (840°F to 2000°F). This creates an obvious and severe burn risk from the heat source (torch or furnace) and the heated workpiece itself, which remains dangerously hot long after the flame is removed.

This intense heat also presents a significant fire hazard. Any flammable materials—such as wood, paper, oils, or cleaning solvents—in the vicinity can be easily ignited by direct flame, sparks, or contact with the hot metal parts.

Hazardous Fumes and Gases

When base metals, filler metals, and chemical fluxes are heated, they release a complex mixture of fumes and gases. Inhaling these can cause both immediate and long-term health problems.

Common hazards include metal fume fever, an acute, flu-like illness caused by inhaling zinc or copper oxides. More severe risks come from filler metals containing cadmium, a highly toxic metal that can cause fatal lung damage. Fluxes often contain fluorides, which can also irritate the respiratory system.

Chemical Exposure from Flux

Brazing fluxes are chemically active compounds designed to clean the metal and prevent oxidation. They are often corrosive and can cause chemical burns to the skin or severe damage to the eyes upon contact.

Handling flux powders or pastes without proper gloves can lead to skin irritation and dermatitis. Accidentally touching your eyes or mouth after handling flux can result in serious injury.

Essential Safety Controls and PPE

A multi-layered safety strategy, starting with the work environment and ending with personal gear, is the only effective way to control brazing hazards.

Engineering Controls: Ventilation is Paramount

The most effective safety measure is to remove hazardous fumes before they can be inhaled. This is achieved through ventilation.

Local Exhaust Ventilation (LEV) is the gold standard. This involves using a fume hood or a flexible snorkel-style extractor placed close to the workpiece to capture fumes directly at the source.

For occasional work where LEV is not feasible, performing the task outdoors or in a large, open space with strong cross-draft from fans can reduce risk, but it is a less reliable method.

Personal Protective Equipment (PPE): Your Last Line of Defense

PPE protects you from hazards that cannot be completely eliminated by engineering controls.

- Eye and Face Protection: Use safety glasses with side shields at a minimum. For torch brazing, goggles or a face shield with appropriate shading (typically Shade #3 to #5) is required to protect against infrared radiation and sparks.

- Respiratory Protection: If ventilation is insufficient to keep fume levels below safe limits, a respirator is required. The type must be selected based on the specific contaminants present (e.g., N95 for particulates, or a cartridge respirator for specific chemical vapors).

- Protective Clothing: Wear flame-resistant (FR) clothing and avoid synthetic fabrics like polyester that can melt and stick to skin. Leather gloves, aprons, and spats provide excellent protection from heat and sparks.

Safe Work Practices

Good habits are a critical part of the safety system. Always clear the work area of all combustibles, and keep a suitable fire extinguisher (e.g., ABC dry chemical) within easy reach. Inspect all equipment, especially gas hoses and regulators, for damage before each use.

Common Pitfalls to Avoid

Even experienced operators can make mistakes. Understanding these common oversights helps reinforce a vigilant safety culture.

Assuming "Quick Jobs" Are Safe

The most frequent error is underestimating the risk of a brief brazing task. Operators may skip setting up proper ventilation or neglect to wear full PPE for a job that only takes a few minutes, exposing themselves to a concentrated dose of hazardous fumes.

Using Incorrect PPE

Not all safety gear is created equal. Using standard clear safety glasses offers no protection from harmful infrared radiation. Wearing cotton or mechanic's gloves instead of thick leather or aluminized gloves provides inadequate protection from the intense heat.

Ignoring the Material Safety Data Sheet (SDS)

The SDS for your filler metal and flux is a critical document. It details the chemical composition, identifies specific hazards (like cadmium), and outlines emergency procedures. Failing to read and understand the SDS means you are working blind to the true risks.

Making the Right Choice for Your Goal

Your safety strategy should scale with the frequency and environment of your work.

- If your primary focus is occasional hobby work: Prioritize working outdoors or in a garage with the main door wide open and a fan creating cross-flow. Always wear shaded eye protection, leather gloves, and natural fiber clothing.

- If your primary focus is daily production or repair: Engineered local exhaust ventilation (LEV) is non-negotiable. This is the only reliable way to protect against chronic fume exposure in a fixed location.

- If your primary focus is managing a team: Your responsibility is to implement a formal safety program that includes providing certified LEV systems, conducting air quality monitoring, training employees on the specific hazards of their materials, and enforcing a strict PPE policy.

A proactive and informed approach to safety transforms brazing from a hazardous task into a controlled and highly effective process.

Summary Table:

| Key Safety Area | Primary Hazard | Essential Control Measure |

|---|---|---|

| Heat & Fire | Severe burns, ignition of combustibles | Flame-resistant clothing, clear work area, fire extinguisher |

| Fumes & Gases | Metal fume fever, toxic inhalation (e.g., cadmium) | Local Exhaust Ventilation (LEV), respirator if needed |

| Chemical Exposure | Skin/eye burns from corrosive flux | Chemical-resistant gloves, eye protection, SDS compliance |

| Work Practices | Accidents from complacency or incorrect equipment | Regular equipment checks, training, and adherence to procedures |

Ensure your lab's brazing operations are safe and efficient with KINTEK.

As specialists in lab equipment and consumables, we understand that safety is paramount in any joining process. Proper ventilation and reliable equipment are the foundation of hazard control. KINTEK provides the durable tools and safety solutions that laboratories need to protect their teams from thermal, chemical, and respiratory risks.

Let us help you build a safer workflow. Contact our experts today to discuss your specific brazing and laboratory safety requirements.

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the difference between a crucible and a furnace? Understanding the Heat Source and Container Partnership

- What are the disadvantages of a muffle furnace? Understanding the Trade-offs for Your Lab

- What is brazing vs soldering? Choose the Right Joining Method for Strength vs. Precision

- Do different liquids melt at different rates? Unlock the Science of Melting Points and Material Properties

- What affects the melting point of a substance? Uncover the Key Factors & Forces