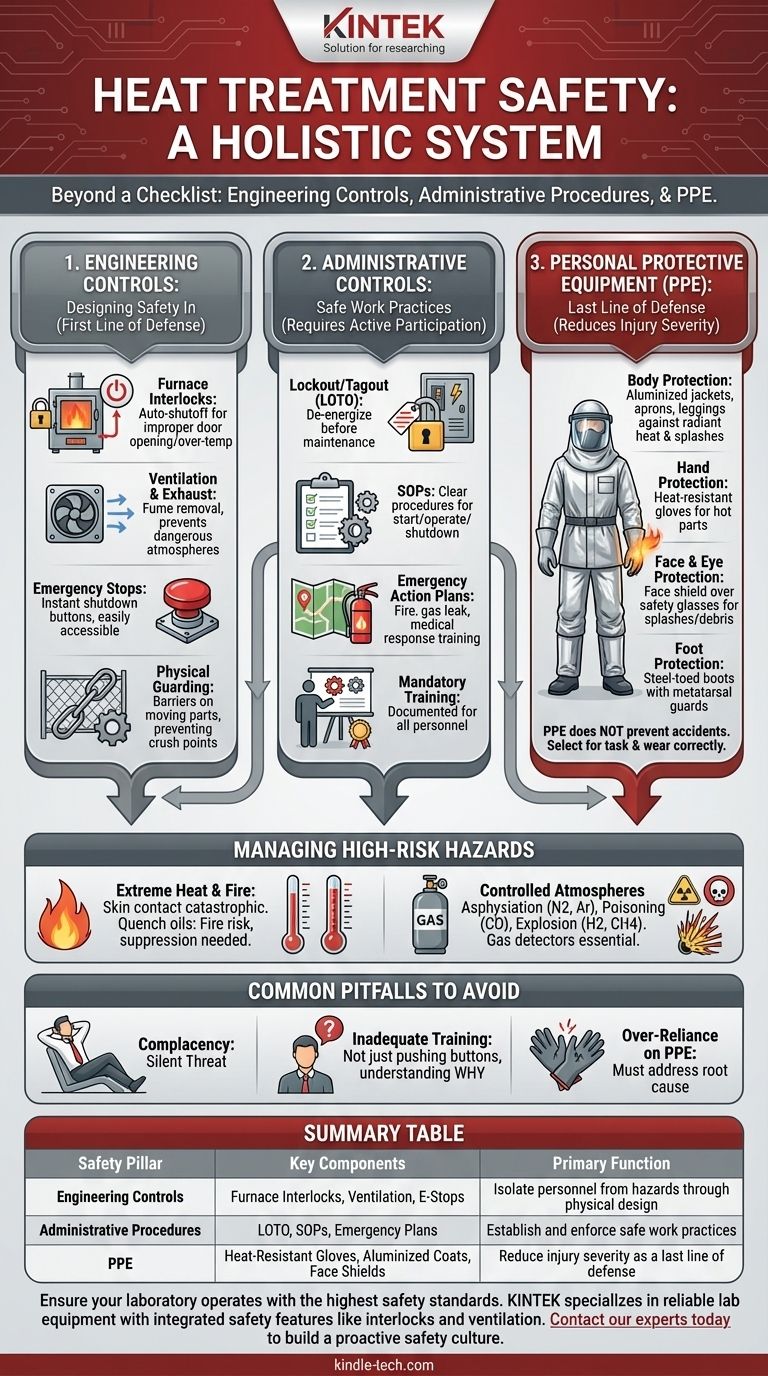

The primary safety precautions for heat treatment focus on protecting personnel from extreme temperatures, hazardous atmospheres, and mechanical dangers. This is achieved through a combination of engineering controls like furnace interlocks and ventilation, strict administrative procedures like Lockout/Tagout (LOTO), and the mandatory use of specialized Personal Protective Equipment (PPE) such as aluminized coats and heat-resistant gloves.

Heat treatment safety is not a checklist, but a system. Viewing it through the three pillars of Engineering Controls, Administrative Procedures, and Personal Protective Equipment (PPE) ensures that risks are managed from the design of the facility down to the actions of the individual operator.

The Core Principles of Heat Treatment Safety

Effective safety programs are built in layers, starting with the most reliable methods. Relying on just one aspect, such as PPE, is a common and dangerous mistake.

Engineering Controls: Designing Safety In

Engineering controls are physical changes to the workplace that isolate people from the hazard. They are the first and most effective line of defense.

- Furnace Interlocks: Modern furnaces must have interlocks that automatically shut off power or gas flow if a door is opened improperly or if an over-temperature condition occurs.

- Ventilation and Exhaust: Proper ventilation is critical. It removes harmful fumes from quenching, toxic byproducts from heating, and prevents the buildup of dangerous process atmospheres.

- Emergency Stops: All equipment must be fitted with clearly marked, easily accessible emergency stop buttons that can shut down all operations instantly.

- Physical Guarding: Guards on moving parts, chains, and automated transfer mechanisms are essential to prevent crushing and pinch-point injuries.

Administrative Controls: Establishing Safe Work Practices

These are the procedures and policies that dictate how work is performed safely. They require active participation and rigorous training.

- Lockout/Tagout (LOTO): Before any maintenance or repair, equipment must be de-energized and locked out. This is a non-negotiable procedure to prevent accidental startup.

- Standard Operating Procedures (SOPs): Clear, written procedures for starting, operating, and shutting down furnaces and related equipment must be established and followed every time.

- Emergency Action Plans: Every operator must be trained on what to do in case of a fire, gas leak, or medical emergency. This includes knowing the location of fire extinguishers, alarms, and emergency exits.

- Mandatory Training: Regular, documented training on hazards, procedures, and the proper use of PPE is essential for all personnel, including supervisors and maintenance staff.

Personal Protective Equipment (PPE): The Last Line of Defense

PPE does not prevent an accident; it only reduces the severity of an injury when all other controls have failed. It must be selected for the specific task and worn correctly.

- Body Protection: Aluminized or other heat-retardant jackets, aprons, and leggings protect against intense radiant heat and molten metal or salt splashes.

- Hand Protection: Heat-resistant gloves are required for handling hot parts. The type of glove must be matched to the temperature.

- Face and Eye Protection: A face shield worn over safety glasses is mandatory when loading/unloading furnaces or working near quench tanks to protect against splashes and flying debris.

- Foot Protection: Steel-toed boots, often with metatarsal guards, protect feet from falling objects and hot materials.

Managing Specific High-Risk Hazards

While the principles above apply broadly, certain aspects of heat treatment carry unique and severe risks that demand special attention.

The Hazard of Extreme Heat and Fire

The most obvious danger is temperature. Skin contact with a part at 1500°F (815°C) is instantaneous and catastrophic.

Quench oils are a primary fire risk. If a part is not fully submerged, or if the oil temperature exceeds its flash point, a fire can easily ignite. Fire suppression systems (CO2, dry chemical) must be available and inspected regularly.

The Danger of Controlled Atmospheres

Many processes use atmospheres that are deadly if inhaled.

- Asphyxiation: Inert gases like Nitrogen (N2) and Argon (Ar) displace oxygen. A leak in an enclosed space can lead to asphyxiation in minutes without warning, as these gases are colorless and odorless.

- Poisoning: Endothermic and other carbon-rich gases contain high levels of Carbon Monoxide (CO), a toxic gas.

- Explosion: Flammable gases like Hydrogen (H2) and Methane (CH4) can create an explosive mixture with air if not handled within strict procedural and engineering controls.

Fixed gas detectors with audible and visual alarms are essential in any area where controlled atmospheres are used.

Common Pitfalls to Avoid

Building a true safety culture means recognizing and actively fighting against behaviors that undermine established procedures.

Complacency: The Silent Threat

Performing the same hazardous task daily without incident leads to a false sense of security. This is when operators may be tempted to take shortcuts, such as forgoing a face shield for a "quick" look or bypassing a safety interlock.

Inadequate Training

Simply showing someone how to push a button is not training. Operators must understand why the safety procedures exist and the severe consequences of deviating from them.

Over-Reliance on PPE

Viewing PPE as the primary safety measure is a critical error. If an operator is consistently getting burned through their gloves, the solution is not thicker gloves; it is an engineering or procedural change to eliminate the reason for the contact.

Making the Right Choice for Your Role

Safety is a shared responsibility, but your specific focus will depend on your function within the organization.

- If your primary focus is management or supervision: Champion a culture where safety is non-negotiable. Invest in engineering controls and comprehensive training, and empower your team to stop work if conditions are unsafe.

- If your primary focus is process engineering: Design safety into every step. Specify equipment with robust interlocks, design effective ventilation, and write clear, unambiguous operating procedures.

- If your primary focus is daily operation: Your life depends on your diligence. Never skip a procedure, always wear the correct PPE, and immediately report any unsafe condition or near-miss.

Ultimately, a safe heat treatment operation is one where every person understands the risks and is empowered to manage them proactively.

Summary Table:

| Safety Pillar | Key Components | Primary Function |

|---|---|---|

| Engineering Controls | Furnace Interlocks, Ventilation, Emergency Stops | Isolate personnel from hazards through physical design |

| Administrative Procedures | Lockout/Tagout (LOTO), SOPs, Emergency Plans | Establish and enforce safe work practices |

| Personal Protective Equipment (PPE) | Heat-Resistant Gloves, Aluminized Coats, Face Shields | Reduce injury severity as a last line of defense |

Ensure your laboratory operates with the highest safety standards. KINTEK specializes in providing reliable lab equipment and consumables designed with integrated safety features. Our range of heat treatment furnaces includes critical engineering controls like interlocks and ventilation systems to protect your team. Don't compromise on safety—contact our experts today to find the right equipment for your laboratory's needs and build a proactive safety culture.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Sintering Brazing Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- How do you test for CVD diamonds? Uncover the scientific methods for definitive identification.

- What is fusion in XRF? Achieve Unmatched Accuracy in Elemental Analysis

- What is the number 1 rule of soldering? Master the Heat for Strong, Reliable Connections

- How deep does XRF penetrate? A Guide to Surface-Sensitive Analysis Depth

- What are the applications of thin film? Powering Modern Electronics, Optics, and Energy

- What are the 3 factors that affect the rate of heat transfer by conduction? Master Thermal Control for Your Lab Equipment

- What is the importance of melting process? Master the Foundation of Metal Production

- How can different materials have different heat capacity? Unlocking the Microscopic Secrets of Energy Storage