Proper sample holder maintenance is a multi-step process that combines routine upkeep with more intensive pre-use cleaning. For regular maintenance, the holder should be wiped with a soft, lint-free cloth to remove dust. For more thorough cleaning before an experiment, use a clean cloth or dust-free paper dampened with a suitable solvent like alcohol to remove oils and other impurities, and use a soft-bristled brush for any crevices.

The cleanliness of your sample holder is not a trivial housekeeping task; it is a critical variable that directly impacts the accuracy, reproducibility, and validity of your experimental data. Viewing maintenance as part of the measurement itself is essential for reliable results.

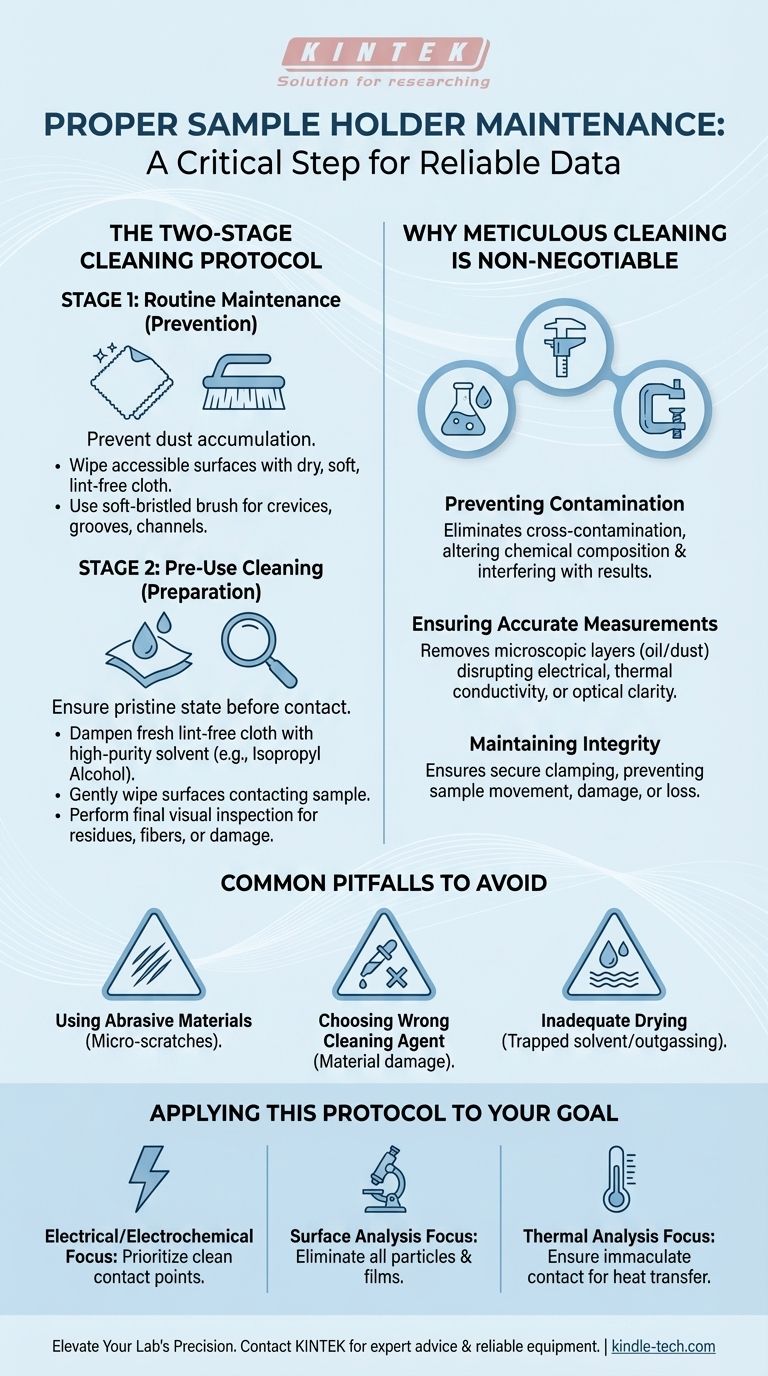

The Two-Stage Cleaning Protocol

Effective maintenance is divided into two distinct phases: the general upkeep you perform regularly and the meticulous cleaning you perform immediately before an experiment.

Stage 1: Routine Maintenance (Prevention)

This stage is about preventing the long-term accumulation of dust and environmental contaminants.

Regularly wipe all accessible surfaces of the sample holder with a dry, soft, lint-free cloth. This simple action prevents dust from settling and becoming compacted in critical areas.

For holders with complex geometries, such as those with grooves, channels, or clamps, use a clean, soft-bristled brush. This allows you to gently dislodge particulate matter from areas a cloth cannot reach.

Stage 2: Pre-Use Cleaning (Preparation)

This stage is about ensuring the holder is in a pristine state immediately before it comes into contact with your sample.

Dampen a new, lint-free cloth or wipe with a high-purity solvent, such as isopropyl alcohol or ethanol. Gently wipe down the surfaces that will contact or be near the sample.

The solvent serves to dissolve and remove invisible films of oil, grease, or residue left behind from previous handling or experiments. This step is critical for a chemically pure surface.

Before placing the sample, always perform a final visual inspection. Look for any remaining residues, fibers from the cloth, or signs of damage like scratches or deformation.

Why Meticulous Cleaning is Non-Negotiable

Failing to properly clean a sample holder introduces uncontrolled variables into your experiment, undermining the integrity of your work.

Preventing Sample Contamination

Residue from a previous sample or a cleaning agent can leach onto your current sample. This can alter its chemical composition, leading to false signals or incorrect analytical results.

Ensuring Accurate Measurements

Even a microscopic layer of oil or dust can have a significant impact. It can act as an insulator, disrupting electrical or thermal conductivity. In optical applications, it can scatter light and obscure imaging.

Maintaining Instrument and Sample Integrity

A dirty holder, especially around clamping mechanisms, may not secure the sample properly. This can lead to sample movement during measurement or, in a worst-case scenario, the sample falling and being damaged or lost.

Common Pitfalls to Avoid

The goal is to clean the holder, not damage it or introduce new contaminants. Avoiding these common mistakes is just as important as the cleaning process itself.

Pitfall 1: Using Abrasive Materials

Never use abrasive cloths, scouring pads, or harsh brushes. These materials create micro-scratches on the holder's surface, which become traps for future contaminants and can be nearly impossible to clean.

Pitfall 2: Choosing the Wrong Cleaning Agent

While alcohol is a common choice, it is not universally appropriate. Always verify that your chosen solvent is compatible with the holder's material. Corrosive or reactive agents can permanently damage the surface.

Pitfall 3: Inadequate Drying or Rinsing

If you use a solvent, you must ensure it has fully evaporated before use. Trapped solvent can outgas in a vacuum system or react with your sample. If you must use a detergent, ensure it is fully rinsed away with a pure solvent.

Applying This Protocol to Your Goal

Your specific experimental goal should guide where you focus the most attention during the cleaning process.

- If your primary focus is electrical or electrochemical measurements: Your top priority is ensuring all electrical contact points are completely free of insulating films (oils, oxides) for a reliable connection.

- If your primary focus is surface analysis (e.g., microscopy, spectroscopy): You must eliminate all particulate and film contaminants that could obstruct the view, alter surface chemistry, or generate false signals.

- If your primary focus is thermal analysis: Confirm the sample-holder contact surfaces are immaculate to guarantee consistent and accurate heat transfer.

By treating your sample holder with this level of methodical care, you are fundamentally strengthening the integrity of your results.

Summary Table:

| Cleaning Stage | Purpose | Key Tools & Materials |

|---|---|---|

| Routine Maintenance (Prevention) | Prevent dust accumulation | Soft, lint-free cloth; soft-bristled brush |

| Pre-Use Cleaning (Preparation) | Remove oils and residues before experiments | Lint-free cloth, high-purity solvent (e.g., isopropyl alcohol) |

Elevate your lab's precision with KINTEK's sample holders and consumables. Our equipment is designed for easy maintenance and reliable performance, ensuring your experiments are free from contamination. Let our experts help you select the right holders and cleaning supplies for your specific application—whether it's electrical measurements, surface analysis, or thermal studies. Contact us today to discuss your laboratory needs and achieve reproducible results!

Visual Guide

Related Products

- Customizable XRD Sample Holders for Diverse Research Applications

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

- Customizable PTFE Wafer Carriers for Semiconductor and Lab Applications

- Button Battery Case for Battery Lab Applications

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- What affects melting point chemistry? A Guide to Molecular Forces and Lattice Energy

- How should a sample holder be handled to ensure its longevity? Protect Your Lab Investment and Data Integrity

- What is the difference between XRF and XRD techniques? A Guide to Choosing the Right Analytical Tool

- Why is an airtight sample holder with a beryllium window required for XRD of sulfide solid electrolytes?

- How can corrosion of the sample holder be prevented when using corrosive chemicals? Protect Your Lab's Integrity