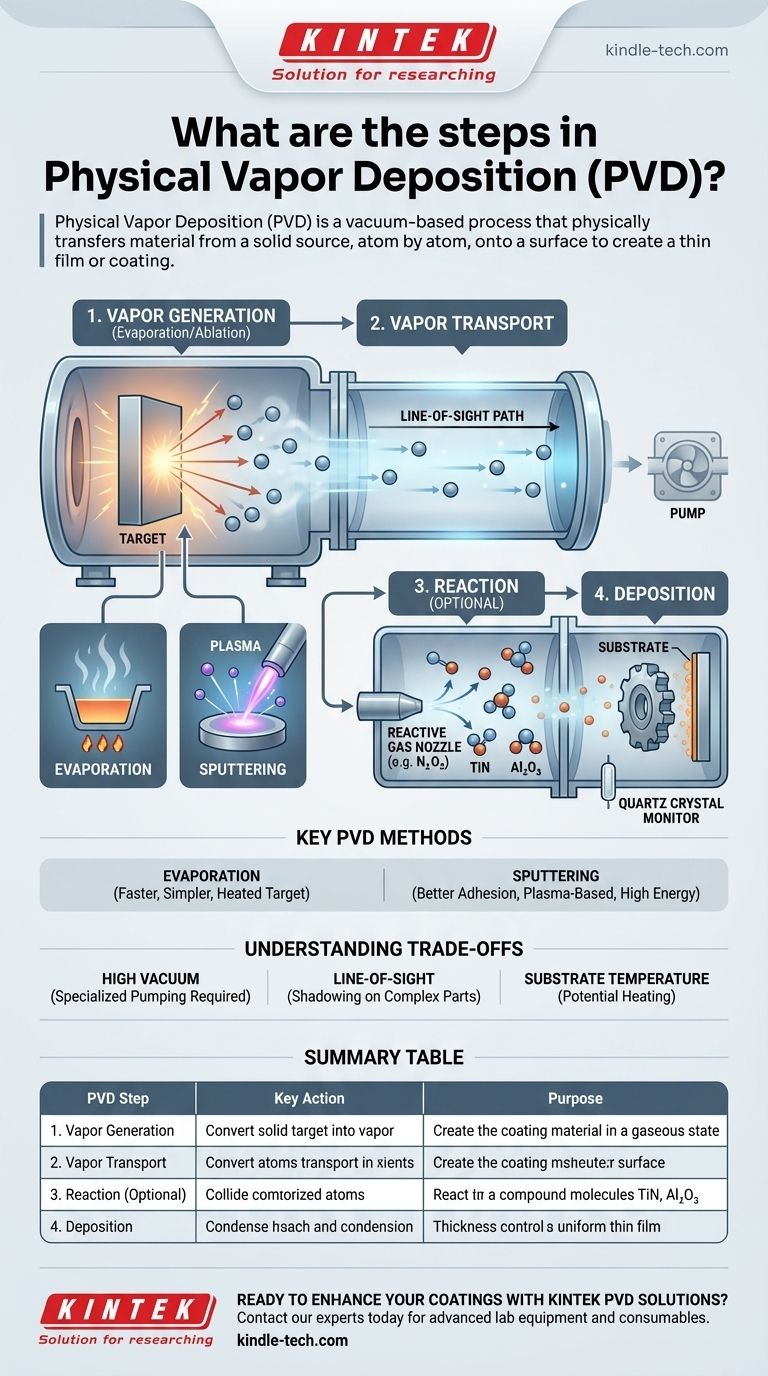

In essence, Physical Vapor Deposition (PVD) is a vacuum-based process that physically transfers material from a solid source, atom by atom, onto a surface to create a thin film or coating. The entire process can be broken down into four fundamental stages: generating a vapor from a source material, transporting that vapor to a substrate, optionally reacting it with gases, and finally, depositing it as a solid film.

The core principle of PVD is not a chemical reaction, but a physical one. It involves taking a solid material, turning it into a vapor inside a vacuum, and allowing it to condense onto a component's surface, forming a high-performance coating.

The PVD Process: A Step-by-Step Breakdown

The PVD process is always conducted inside a vacuum chamber. This controlled environment is critical because it removes atmospheric gases that could otherwise react with and contaminate the coating material.

Step 1: Vapor Generation (Evaporation/Ablation)

The first step is to convert a solid source material, known as the target, into a gaseous or vapor state. This is a purely physical transformation.

This is accomplished using high energy to dislodge atoms from the target. The specific method used defines the type of PVD, with the two most common categories being Evaporation and Sputtering.

Step 2: Vapor Transport

Once the atoms are liberated from the target, they travel through the vacuum chamber toward the part to be coated, which is called the substrate.

This transport phase occurs in a straight line, a characteristic known as line-of-sight. The vacuum environment ensures the atoms do not collide with air molecules, which would impede their path and introduce impurities.

Step 3: Reaction (Optional)

In many advanced PVD applications, this transport phase is used to create specific compound materials. A reactive gas, such as nitrogen or oxygen, is precisely introduced into the chamber.

The vaporized metal atoms react with this gas mid-flight or on the substrate surface. This is how coatings like durable gold-colored Titanium Nitride (TiN) or wear-resistant Aluminum Oxide (Al2O3) are formed.

Step 4: Deposition

Finally, the stream of vaporized material reaches the substrate and condenses back into a solid state.

This builds up, atom by atom, to form a thin, dense, and highly adherent film. The thickness of this film is carefully monitored and controlled during the process, often using a quartz crystal monitor to ensure it meets exact specifications.

Key PVD Methods: Evaporation vs. Sputtering

While many PVD variants exist, they primarily fall into two camps based on how the vapor is generated.

Evaporation

In thermal or e-beam evaporation, the target material is heated in the vacuum until it boils and evaporates, much like boiling water creates steam. This vapor then travels to and condenses on the substrate. This method is generally faster and simpler.

Sputtering

In sputtering, instead of heat, a plasma is created in the chamber. High-energy ions from this plasma are accelerated to bombard the target, physically knocking atoms loose like a sandblaster. This method provides excellent film adhesion and uniformity.

Understanding the Trade-offs

PVD is a powerful technology, but it's essential to understand its inherent characteristics and limitations to apply it correctly.

The Need for High Vacuum

Achieving and maintaining a high vacuum is fundamental to PVD. This requires specialized, and often expensive, pumping equipment. The vacuum prevents contamination and allows the vapor to travel unimpeded.

Line-of-Sight Deposition

Because the vaporized atoms travel in a straight line, PVD is a line-of-sight process. Areas of a complex part that are "in shadow" will not get coated evenly without sophisticated fixtures that rotate the part during deposition.

Substrate Temperature

While PVD is considered a "cold" process compared to methods like Chemical Vapor Deposition (CVD), the substrate can still heat up significantly. This can be a limiting factor for temperature-sensitive materials like certain plastics.

Making the Right Choice for Your Goal

Selecting the appropriate PVD approach depends entirely on the desired outcome for your component.

- If your primary focus is high purity and simple geometries: Thermal evaporation is often a cost-effective and rapid solution.

- If your primary focus is maximum durability and film density: Sputtering is the superior choice due to the higher energy of the depositing atoms, which creates a more robust coating.

- If your primary focus is creating a specific ceramic coating (e.g., a nitride): You must use a reactive PVD process where gases are intentionally introduced during the transport stage.

- If your primary focus is coating a complex 3D object: You must plan for intricate part fixturing and rotation to overcome the line-of-sight nature of the deposition.

By understanding these fundamental steps and trade-offs, you can effectively leverage PVD to achieve a wide range of high-performance surface modifications.

Summary Table:

| PVD Step | Key Action | Purpose |

|---|---|---|

| 1. Vapor Generation | Convert solid target into vapor | Create the coating material in a gaseous state |

| 2. Vapor Transport | Atoms travel through vacuum | Move material to substrate without contamination |

| 3. Reaction (Optional) | Introduce reactive gases (e.g., N₂) | Form compound coatings like Titanium Nitride (TiN) |

| 4. Deposition | Atoms condense on substrate | Build a dense, adherent thin film |

Ready to enhance your materials with high-performance PVD coatings?

At KINTEK, we specialize in providing advanced lab equipment and consumables for precise Physical Vapor Deposition processes. Whether you need sputtering systems for maximum durability or evaporation tools for high-purity applications, our solutions are designed to meet your specific laboratory needs.

Contact our experts today to discuss how our PVD technology can improve your coating results, increase component longevity, and drive your research forward.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What are the drawbacks of PECVD? Understanding the Trade-offs of Low-Temperature Deposition

- What are the advantages of plasma enhanced CVD? Enable Low-Temperature, High-Quality Thin Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What is plasma enhanced chemical vapor deposition PECVD equipment? A Guide to Low-Temperature Thin Film Deposition