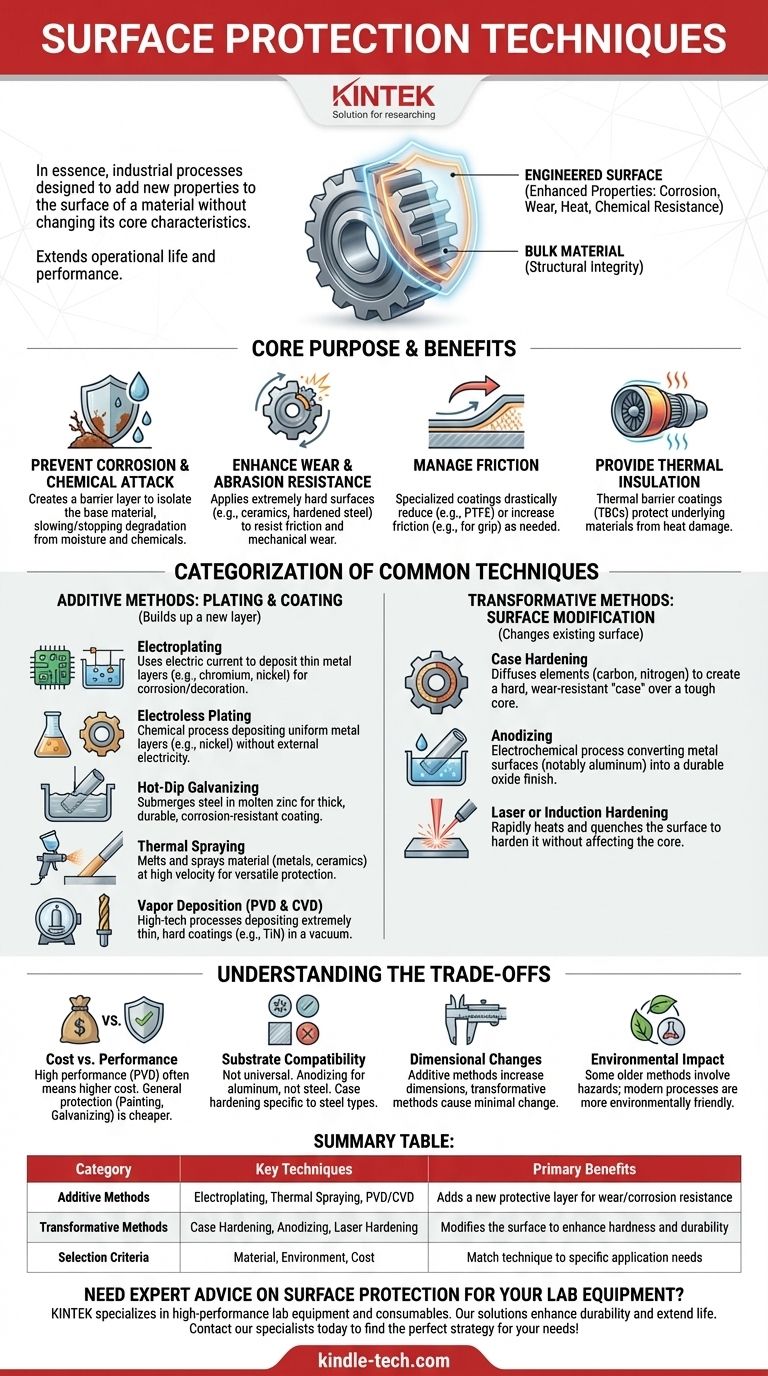

In essence, surface protection techniques are a range of industrial processes designed to add new properties to the surface of a material without changing its core characteristics. These methods apply a specialized layer or modify the surface itself to enhance its resistance to wear, corrosion, heat, or chemical attack, thereby extending the component's operational life and performance.

The central goal of surface protection is not simply to cover a material, but to create a composite system where the bulk material provides structural integrity and the engineered surface provides the necessary environmental resistance. Choosing the right technique depends entirely on matching the method to the specific material, its operating environment, and the primary failure mode you need to prevent.

The Core Purpose of Surface Protection

At its heart, surface protection engineering allows for a "best of both worlds" approach. You can use a strong, tough, and cost-effective material like steel for the main body of a component while creating a highly specialized surface that can withstand extreme conditions.

Preventing Corrosion and Chemical Attack

Many metals, particularly steel, are susceptible to degradation from moisture and chemicals. Surface protection techniques create a barrier layer that isolates the base metal from the corrosive environment, significantly slowing or stopping rust and chemical damage.

Enhancing Wear and Abrasion Resistance

In applications involving moving parts, friction and abrasion can quickly wear down components. By applying an extremely hard surface layer, such as a ceramic or a hardened steel case, you can dramatically increase the part's resistance to mechanical wear.

Managing Friction

Surface engineering is not just about durability; it's also about controlling performance. Specialized coatings can be used to either drastically reduce friction (like PTFE coatings on non-stick pans) or to increase it for applications requiring grip (like thermal-sprayed coatings on brake rotors).

Providing Thermal Insulation

In high-temperature environments like jet engines or automotive exhausts, thermal barrier coatings (TBCs) are applied. These ceramic-based layers have very low thermal conductivity, protecting the underlying metal alloy from heat damage that would otherwise compromise its strength.

A Categorization of Common Techniques

Surface protection methods can be broadly divided into two categories: those that add a new layer of material to the surface, and those that transform the existing surface itself.

Additive Methods: Plating and Coating

These techniques build up a new layer on top of the substrate material.

- Electroplating: This process uses an electric current to deposit a thin layer of one metal (like chromium, nickel, or zinc) onto the surface of another. It's widely used for corrosion resistance and decorative finishes.

- Electroless Plating: A purely chemical process that deposits a layer of metal, most commonly nickel, without the use of an external electrical current. This results in an exceptionally uniform coating, even on complex shapes.

- Hot-Dip Galvanizing: A robust and cost-effective method for protecting steel, where the part is submerged in a bath of molten zinc. This creates a thick, durable, and corrosion-resistant alloyed coating.

- Thermal Spraying: This versatile process involves melting a material (in powder or wire form) and spraying it at high velocity onto a surface. It can be used to apply metals, ceramics, and plastics for wear, corrosion, and thermal protection.

- Vapor Deposition (PVD & CVD): These are high-tech vacuum processes that deposit extremely thin but very hard coatings. Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) are famous for the gold-colored Titanium Nitride (TiN) coating seen on high-performance drill bits.

Transformative Methods: Surface Modification

These techniques change the chemical composition or microstructure of the existing surface.

- Case Hardening: A group of processes, including carburizing and nitriding, that diffuse elements like carbon or nitrogen into the surface of steel. This creates an intensely hard, wear-resistant "case" while leaving the inner "core" tough and ductile.

- Anodizing: An electrochemical process that converts the surface of a metal, most notably aluminum, into a durable, corrosion-resistant, and decorative anodic oxide finish. It is not an applied coating but an integral part of the metal.

- Laser or Induction Hardening: These methods use a focused energy source (a laser beam or magnetic field) to rapidly heat the surface of a steel part, which is then quenched. This heat treatment hardens the surface without affecting the core.

Understanding the Trade-offs

There is no single "best" surface protection technique. The optimal choice is always a balance of performance requirements, material compatibility, and cost.

Cost vs. Performance

High-performance vacuum coatings like PVD offer exceptional hardness and low friction but come at a significant cost. Conversely, methods like painting or hot-dip galvanizing provide excellent general corrosion protection at a much lower price point.

Substrate Compatibility

Every process has limitations. Anodizing is highly effective for aluminum but cannot be used on steel. Case hardening techniques are specifically designed for certain types of steel and are ineffective on other alloys.

Dimensional Changes

Additive processes like thermal spraying or electroplating increase the dimensions of the part. This change must be accounted for in the initial design to ensure the final product meets its required tolerances. Transformative methods like case hardening cause minimal dimensional change.

Environmental Impact

Some older, traditional methods, such as hexavalent chromium plating, involve hazardous chemicals and generate toxic waste. Modern regulations are driving a shift toward more environmentally benign processes like thermal spray or certain PVD coatings.

Making the Right Choice for Your Goal

Selecting the correct technique begins with identifying your primary challenge.

- If your primary focus is preventing atmospheric corrosion on steel structures: Hot-dip galvanizing or a high-performance industrial paint system offers cost-effective, robust protection.

- If your primary focus is increasing the surface hardness and wear resistance of steel gears: Case hardening techniques like carburizing or nitriding are the industry standard for creating a durable component.

- If your primary focus is creating a high-performance, low-friction surface on cutting tools: Physical Vapor Deposition (PVD) coatings like TiN or AlTiN are the ideal choice for extending tool life.

- If your primary focus is providing corrosion and wear resistance for aluminum components: Anodizing is the most effective and widely used method to create an integral protective layer.

By understanding the fundamental purpose behind each method, you can select a surface protection strategy that extends the life and enhances the performance of your components.

Summary Table:

| Category | Key Techniques | Primary Benefits |

|---|---|---|

| Additive Methods | Electroplating, Thermal Spraying, PVD/CVD | Adds a new protective layer for wear/corrosion resistance |

| Transformative Methods | Case Hardening, Anodizing, Laser Hardening | Modifies the surface to enhance hardness and durability |

| Selection Criteria | Material, Environment, Cost | Match technique to specific application needs |

Need expert advice on surface protection for your lab equipment? KINTEK specializes in providing high-performance lab equipment and consumables, ensuring your components withstand harsh conditions. Our solutions enhance durability, reduce maintenance, and extend the life of your critical tools. Contact our specialists today to find the perfect surface protection strategy for your laboratory needs!

Visual Guide

Related Products

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Warm Isostatic Press for Solid State Battery Research

- Graphite Vacuum Continuous Graphitization Furnace

- Lab Infrared Press Mold

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What are the advantages disadvantages and uses of sheet metal? The Ultimate Guide to Material Selection

- How does hardness change with temperature? Understand the Inverse Relationship to Prevent Failure

- What is titanium used for in manufacturing? Leveraging High-Performance Properties for Critical Applications

- What is the difference between metallic and non-metallic coating? A Guide to Sacrificial vs. Barrier Protection

- Why is platinum unreactive? The Atomic Secrets Behind Its Remarkable Stability