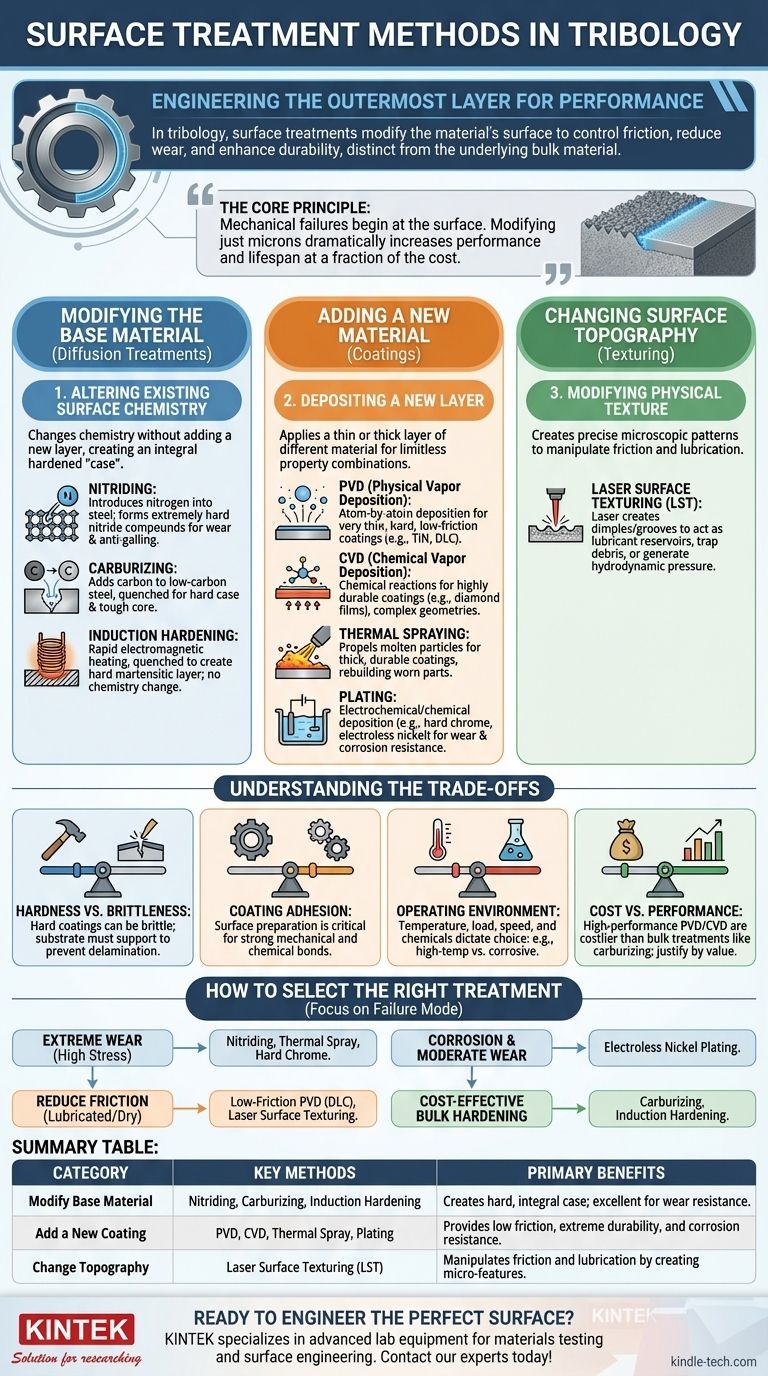

In tribology, surface treatments are methods used to engineer the properties of a material's outermost layer to control friction and reduce wear. These methods fall into three main categories: altering the existing surface chemistry without adding material (like nitriding), applying a new layer of a different material (like coatings), and modifying the surface's physical texture. The goal is to create a surface that is harder, slicker, or more durable than the underlying bulk material.

The core principle is that mechanical failures almost always begin at the surface. By strategically modifying just a few microns of the outermost material, you can dramatically increase the performance, efficiency, and lifespan of an entire component at a fraction of the cost of making the entire part from an exotic material.

Why Surface Engineering is Critical

In any moving mechanical system, the interaction between surfaces dictates performance and reliability. Unmodified surfaces, even when smooth to the touch, are rough at a microscopic level, leading to friction and eventual failure.

The Problem of Friction and Wear

Friction is the resistance to motion between two surfaces in contact. It consumes energy and generates heat, which can degrade lubricants and materials.

Wear is the progressive loss of material from a surface due to mechanical action. It is the primary reason components like bearings, gears, and engine pistons eventually fail.

The Solution: Targeted Modification

Surface treatments address these issues directly. They create a functional surface specifically designed to withstand the unique challenges of its operating environment, such as high loads, corrosive chemicals, or extreme temperatures.

Key Categories of Surface Treatments

Surface treatments are not a single technology but a broad field of different processes, each with specific applications. They are best understood by how they modify the component.

Category 1: Modifying the Base Material

These methods, often called diffusion treatments, change the chemistry of the existing surface without adding a distinct new layer. They create a hardened "case" that is integral to the part itself.

- Nitriding: Introduces nitrogen into the surface of steel alloys, forming extremely hard nitride compounds. This creates excellent wear resistance and anti-galling properties.

- Carburizing: Adds carbon to the surface of low-carbon steel, which is then quenched to create a hard, wear-resistant case with a tough, ductile core.

- Induction Hardening: Uses electromagnetic heating to rapidly heat the surface of a steel part, which is then quenched. This creates a hard martensitic layer without changing the surface chemistry.

Category 2: Adding a New Material (Coatings)

These methods involve depositing a thin or thick layer of a different material onto the substrate. This allows for a nearly limitless combination of properties.

- Physical Vapor Deposition (PVD): A process where a solid material is vaporized in a vacuum and deposited atom-by-atom onto a component. It produces very thin, hard, and low-friction coatings like Titanium Nitride (TiN) and Diamond-Like Carbon (DLC).

- Chemical Vapor Deposition (CVD): Uses chemical reactions from precursor gases to deposit a layer onto a heated substrate. It is excellent for creating highly durable coatings, such as diamond films, and can coat complex geometries uniformly.

- Thermal Spraying: Propels molten or semi-molten particles onto a surface to build up a thick, durable coating. This is often used for rebuilding worn parts or providing extreme wear and corrosion resistance.

- Plating: Includes processes like electroplating (e.g., hard chrome) and electroless nickel plating. These methods use electrochemical or chemical reactions to deposit a metallic layer that enhances wear and corrosion resistance.

Category 3: Changing the Surface Topography

This modern approach involves creating a precisely controlled pattern of microscopic features on a surface to manipulate friction and lubrication.

- Laser Surface Texturing (LST): Uses a laser to create an array of tiny dimples or grooves on a surface. These features can act as lubricant reservoirs, trap wear debris, or generate hydrodynamic pressure to separate sliding surfaces.

Understanding the Trade-offs

Choosing a surface treatment is not about finding the "hardest" or "slickest" option. It's about finding the optimal balance for a specific application.

Hardness vs. Brittleness

An extremely hard coating can be brittle. If the underlying component flexes under load, a brittle coating can crack and flake off (delaminate), leading to rapid failure. The toughness of the substrate must support the hard surface.

Coating Adhesion

The most advanced coating is useless if it does not properly adhere to the substrate. Surface preparation (cleaning and roughening) is arguably the most critical step in any coating process to ensure a strong mechanical and chemical bond.

Operating Environment

The environment dictates the choice. A treatment that excels at high temperatures may fail in a corrosive chemical environment. Factors like load, speed, temperature, and chemical exposure must all be considered.

Cost vs. Performance

High-performance processes like PVD and CVD require expensive vacuum equipment and are more costly than traditional bulk treatments like carburizing. The treatment must be justified by the required performance gain and component value.

How to Select the Right Treatment

Your choice should be driven by the primary failure mode you are trying to prevent.

- If your primary focus is extreme wear resistance under high contact stress: Consider diffusion treatments like nitriding or thick, hard coatings like thermal spray or hard chrome.

- If your primary focus is reducing friction in lubricated or dry conditions: Low-friction PVD coatings like Diamond-Like Carbon (DLC) are an excellent choice, as is laser surface texturing.

- If your primary focus is both corrosion and moderate wear: Electroless nickel plating offers a balanced and cost-effective solution that provides excellent coverage.

- If your primary focus is cost-effective hardening of steel components in bulk: Traditional case-hardening methods like carburizing or induction hardening remain the industry standard.

Ultimately, selecting the correct surface treatment transforms a standard component into a highly engineered, reliable, and high-performance asset.

Summary Table:

| Category | Key Methods | Primary Benefits |

|---|---|---|

| Modify Base Material | Nitriding, Carburizing, Induction Hardening | Creates a hard, integral case; excellent for wear resistance. |

| Add a New Coating | PVD, CVD, Thermal Spray, Plating | Provides low friction, extreme durability, and corrosion resistance. |

| Change Topography | Laser Surface Texturing (LST) | Manipulates friction and lubrication by creating micro-features. |

Ready to engineer the perfect surface for your components?

Choosing the right surface treatment is critical for performance and longevity. At KINTEK, we specialize in advanced lab equipment and consumables for materials testing and surface engineering. Our solutions help you select and validate the ideal tribological treatment—whether it's for wear resistance, friction reduction, or corrosion protection.

Let our expertise guide you to enhance your component's lifespan and reliability. Contact our experts today to discuss your specific application needs!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition