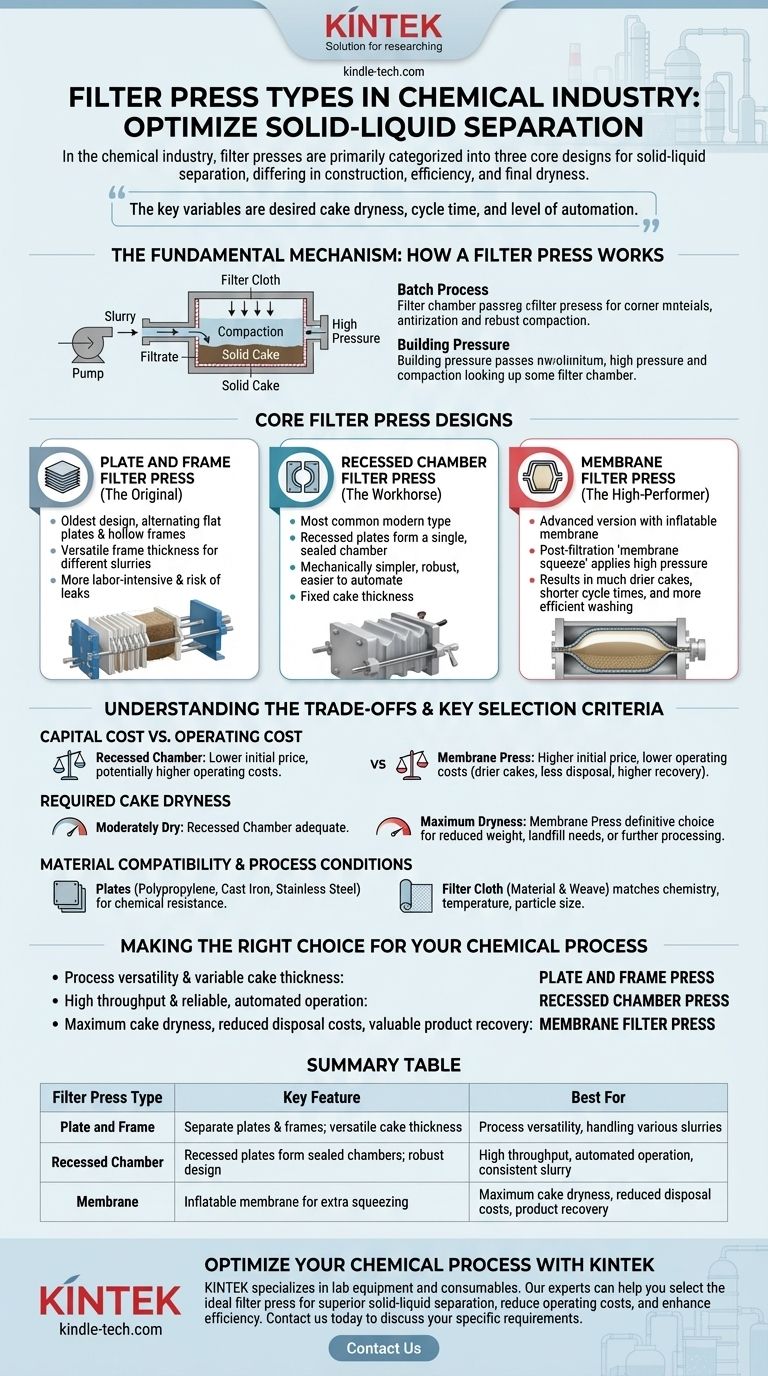

In the chemical industry, filter presses are primarily categorized into three core designs: the Plate and Frame Press, the Recessed Chamber Press, and the Membrane Filter Press. While all perform solid-liquid separation, they differ significantly in their construction, operational efficiency, and the final dryness of the filtered solids, making the choice between them critical for process optimization.

The decision is not about which filter press is universally "best," but which technology is best suited for your specific chemical slurry, operational goals, and economic constraints. The key variables are desired cake dryness, cycle time, and level of automation.

The Fundamental Mechanism: How a Filter Press Works

A filter press operates on a simple principle: forcing a liquid-solid slurry through a series of filter chambers under high pressure.

The Batch Process

The process is a batch cycle. Slurry is pumped into the press, filling the chambers. The liquid (filtrate) passes through the filter cloth lining each chamber wall, while the solid particles (cake) are trapped and accumulate inside.

Building Pressure

As the cake builds, the pressure required to pump more slurry increases. This pressure compacts the cake, squeezing out additional liquid. The cycle ends when the chambers are full of solid cake and the filtrate flow nearly stops.

Core Filter Press Designs in Chemical Processing

Each design represents an evolution in technology, built to solve specific operational challenges common in chemical manufacturing.

Plate and Frame Filter Press (The Original)

This is the oldest design, consisting of a series of flat plates and hollow frames arranged alternately. The filter cloth is draped over each plate.

The slurry is pumped into the hollow frames, and the cake forms within them. The thickness of the cake is determined by the thickness of the frame.

This design offers great versatility, as frame thickness can be changed to accommodate different types of slurries. However, it is more labor-intensive to clean and has more sealing surfaces, increasing the risk of leaks.

Recessed Chamber Filter Press (The Workhorse)

This is the most common type in modern industrial applications. It eliminates the separate frames by using plates with a recessed chamber on each side.

When two recessed plates are pressed together, they form a single, sealed chamber for the filter cake to form in. This design is mechanically simpler, more robust, and easier to automate.

Its primary limitation is that the cake thickness is fixed by the depth of the plate recess, offering less process flexibility than a plate and frame model.

Membrane Filter Press (The High-Performer)

The membrane press is an advanced version of the recessed chamber press. It includes a flexible, inflatable membrane on one or both sides of the chamber.

After the initial filtration cycle, this membrane is inflated with water or air. This "membrane squeeze" applies high mechanical pressure directly to the filter cake, physically squeezing out significantly more liquid than pressure filtration alone.

This results in much drier filter cakes, shorter cycle times, and more efficient washing cycles, which is critical when trying to recover valuable product from the cake or minimize liquid in a waste stream.

Understanding the Trade-offs and Key Selection Criteria

Choosing the correct filter press requires a clear understanding of your process goals and the nature of your chemical slurry.

Capital Cost vs. Operating Cost

A recessed chamber press typically has a lower initial purchase price. However, a membrane press, while more expensive upfront, can dramatically lower operating costs.

Drier cakes from a membrane press mean lower transportation and disposal fees for waste products. It can also mean higher recovery of valuable filtrate, leading to a rapid return on investment.

Required Cake Dryness

If a moderately dry, handleable cake is sufficient, a recessed chamber press is often adequate.

If achieving the maximum possible cake dryness is your primary goal—to reduce shipping weight, meet landfill requirements, or prepare the cake for further processing—the membrane press is the definitive choice.

Material Compatibility and Process Conditions

In the chemical industry, materials of construction are paramount. Plates are typically made from polypropylene, which has broad chemical resistance. However, for extreme temperatures, pressures, or highly aggressive solvents, cast iron or stainless steel plates may be required.

The filter cloth is just as critical. The material (e.g., polypropylene, polyester, nylon) and weave must be selected to match the chemistry, temperature, and particle size of your slurry to prevent blinding and ensure a long service life.

Making the Right Choice for Your Chemical Process

Your final decision should be guided by a clear analysis of your primary operational driver.

- If your primary focus is process versatility and handling various cake thicknesses: A plate and frame press offers the most flexibility, though it often requires more manual intervention.

- If your primary focus is high throughput and reliable, automated operation for a consistent slurry: The recessed chamber press is the industry standard and a robust, cost-effective choice.

- If your primary focus is achieving maximum cake dryness to reduce disposal costs or recover valuable product: A membrane filter press is the superior technology, providing an extra squeeze for ultimate dewatering.

By matching the filter press technology to your specific process needs, you ensure an efficient and cost-effective solid-liquid separation solution.

Summary Table:

| Filter Press Type | Key Feature | Best For |

|---|---|---|

| Plate and Frame | Separate plates & frames; versatile cake thickness | Process versatility, handling various slurries |

| Recessed Chamber | Recessed plates form sealed chambers; robust design | High throughput, automated operation, consistent slurry |

| Membrane | Inflatable membrane for extra squeezing | Maximum cake dryness, reduced disposal costs, product recovery |

Optimize your chemical process with the right filter press technology. KINTEK specializes in lab equipment and consumables, serving laboratory needs with precision and reliability. Our experts can help you select the ideal filter press to achieve superior solid-liquid separation, reduce operating costs, and enhance efficiency. Contact us today to discuss your specific requirements and discover how our solutions can benefit your operation!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Warm Isostatic Press for Solid State Battery Research

People Also Ask

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation