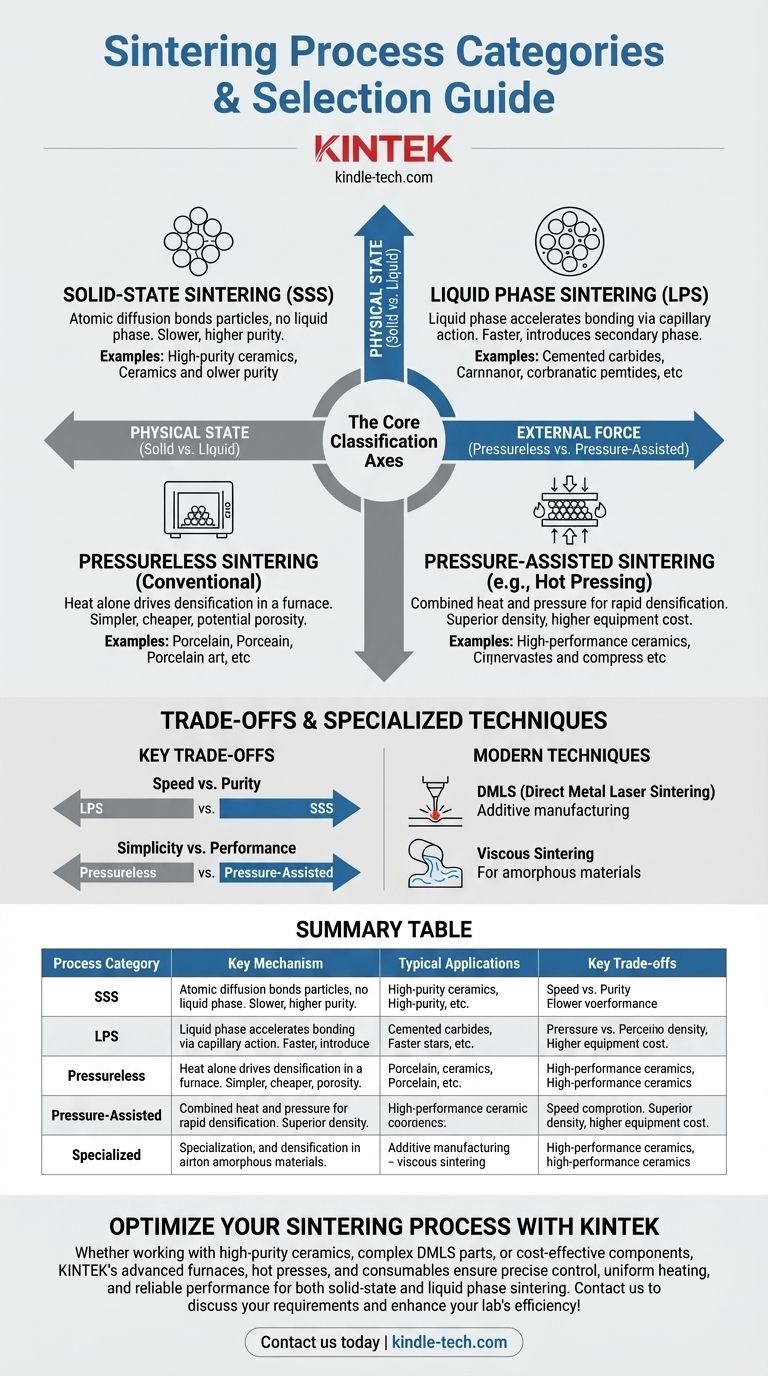

At its core, sintering processes are primarily categorized along two key axes: the physical state of the material (solid versus liquid) and the application of external force (pressureless versus pressure-assisted). While many specific techniques exist, such as Direct Metal Laser Sintering (DMLS) or hot pressing, they are all variations built upon these fundamental principles to reduce porosity and bond particles into a coherent, solid mass.

Understanding the landscape of sintering requires moving beyond a simple list of names. The key is to classify any method by first asking, "Is a liquid phase present?" and second, "Is external pressure applied?" Answering these two questions reveals the core mechanism and trade-offs of the process.

The Fundamental Divide: Solid vs. Liquid Phase

The most significant distinction between sintering types is whether the material remains entirely solid or if a liquid phase is intentionally introduced during the heating process. This choice dictates the speed, temperature, and resulting microstructure of the final part.

Solid-State Sintering (SSS)

In solid-state sintering, also called solid-phase sintering, the powder compact remains completely in the solid state throughout the heating cycle.

The driving force is the reduction of surface energy. At high temperatures, atoms diffuse across the boundaries of adjacent particles, causing them to bond and grow together, which slowly eliminates the pore spaces between them.

This method is often preferred when material purity is paramount, as no additives are needed to create a liquid phase.

Liquid Phase Sintering (LPS)

Liquid phase sintering involves the presence of a small amount of a liquid phase at the sintering temperature. This liquid is typically formed by an additive with a lower melting point than the main powder material.

The liquid wets the solid particles, and capillary action pulls them together, dramatically accelerating densification. The liquid also acts as a rapid transport medium for material to dissolve and re-precipitate, filling the remaining voids.

LPS generally allows for faster processing at lower temperatures compared to solid-state sintering for the same material.

The Role of External Force: Pressureless vs. Pressure-Assisted

The second major classification is based on whether external pressure is used in conjunction with heat. This choice directly impacts the final density, processing time, and equipment cost.

Pressureless Sintering (Conventional Sintering)

This is the most common and straightforward method, where a compacted powder "green body" is simply heated in a furnace or kiln without any external pressure.

Heat is the sole driving force for densification. This technique is widely used for materials like porcelain and other ceramics where high cost and complexity are not justified.

Pressure-Assisted Sintering

In this approach, external pressure is applied to the powder compact simultaneously with heat. Hot Pressing is a primary example of this category.

The combination of heat and pressure significantly accelerates densification, allowing for the use of lower temperatures or shorter cycle times. This leads to parts with higher density, finer grain structure, and superior mechanical properties.

Understanding the Trade-offs

No single sintering process is universally superior. The optimal choice depends on a balance of material requirements, production cost, and desired final properties.

Simplicity vs. Performance

Pressureless sintering is simpler and less expensive due to the low cost of kilns and furnaces. However, it may require higher temperatures and longer times to achieve full density, potentially leading to unwanted grain growth or residual porosity.

Pressure-assisted sintering, conversely, yields superior density and mechanical properties but requires complex, high-cost equipment like a hot press.

Speed vs. Purity

Liquid Phase Sintering (LPS) offers a significant speed advantage and can lower energy costs by reducing the required temperature. The trade-off is the introduction of a secondary phase into the final material, which must be carefully controlled.

Solid-State Sintering (SSS) produces a purer final component but is a fundamentally slower diffusion-controlled process, requiring more time and thermal energy.

A Look at Modern & Specialized Techniques

Building on these fundamentals, several advanced and specialized processes have been developed for specific applications.

Direct Metal Laser Sintering (DMLS)

This is an additive manufacturing (3D printing) technique. A high-power laser scans a bed of metal powder, melting and fusing particles locally, layer by layer, to build a complex part.

DMLS is essentially a highly localized and rapid sintering process, often involving a transient liquid phase, that allows for the creation of intricate metal components directly from a digital model.

Viscous Sintering

This specialized process applies to amorphous materials like glass. Instead of atomic diffusion, densification occurs as the heated particles soften and flow together under surface tension, much like merging droplets of a very thick liquid.

Making the Right Choice for Your Goal

Selecting the correct process requires aligning the technique's capabilities with your project's primary objective.

- If your primary focus is cost-effective production of non-critical parts: Conventional, pressureless sintering is the most economical and straightforward choice.

- If your primary focus is maximum density and mechanical strength: Pressure-assisted methods like hot pressing are required to achieve peak performance in technical ceramics and composites.

- If your primary focus is speed and lower processing temperatures: Liquid Phase Sintering is an excellent option, provided the presence of a second phase is acceptable.

- If your primary focus is manufacturing complex, custom metal geometries: Advanced techniques like DMLS are the industry standard for rapid prototyping and production.

Ultimately, effective material design involves matching the sintering process to the unique properties of your material and the performance demands of the final application.

Summary Table:

| Process Category | Key Mechanism | Typical Applications | Key Trade-offs |

|---|---|---|---|

| Solid-State Sintering (SSS) | Atomic diffusion bonds particles without liquid phase. | High-purity ceramics, technical materials. | Slower process, higher purity. |

| Liquid Phase Sintering (LPS) | Liquid phase accelerates bonding via capillary action. | Cemented carbides, some ceramics. | Faster, but introduces secondary phase. |

| Pressureless Sintering | Heat alone drives densification in a furnace. | Porcelain, cost-effective parts. | Simpler and cheaper, but may have residual porosity. |

| Pressure-Assisted Sintering (e.g., Hot Pressing) | Combined heat and pressure for rapid densification. | High-performance ceramics, composites. | Superior density, but higher equipment cost. |

| Specialized (e.g., DMLS) | Laser-based, layer-by-layer fusion for complex shapes. | Additive manufacturing of metal parts. | High complexity parts, but specialized equipment. |

Optimize Your Sintering Process with KINTEK

Choosing the right sintering method is critical for achieving the desired density, purity, and mechanical properties in your materials. Whether you are working with high-purity ceramics, complex metal parts via DMLS, or cost-effective components, KINTEK's advanced lab equipment and consumables are designed to meet your specific sintering needs.

Our range of furnaces, hot presses, and supporting consumables ensures precise temperature control, uniform heating, and reliable performance for both solid-state and liquid phase sintering applications. Let us help you enhance your lab's efficiency and achieve superior results.

Contact us today to discuss your sintering requirements and discover how KINTEK can support your laboratory's success!

Visual Guide

Related Products

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Spark Plasma Sintering Furnace SPS Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

People Also Ask

- What is the carbon footprint of diamond mining? Uncovering the True Environmental and Ethical Cost

- What are the disadvantages of electric arc furnace? High Costs, Power Demand, and Operational Challenges

- What are the guidelines to follow while heating substances in the laboratory? Ensure Safe and Controlled Heating Processes

- What are the safety precautions for forging? A Complete Guide to Protecting Against Heat, Force, and Fumes

- Why is the control of moisture evaporation critical in the Cu-Cl cycle? Optimize Particle Quality & Reactivity

- What are three biomass materials that are pelletized? Wood, Agricultural Waste & Energy Crops

- What are the advantages of filter press? Achieve Maximum Dewatering & Superior Filtrate Clarity

- What is argon gas used for? Unlock the Power of Inertness for Welding, Lighting & More