In short, tube furnace tubes are most commonly made from high-purity ceramics, quartz, or specialized metal alloys. These materials are chosen for their ability to withstand extreme temperatures and resist chemical reactions. The furnace body and its insulation, by contrast, are made from different materials like stainless steel and ceramic fiber boards.

The core principle is that the tube material is not an afterthought; it is a critical component dictated by your experiment's maximum temperature, chemical environment, and required atmosphere. Choosing the correct material is essential for achieving accurate results and ensuring safety.

The Role of the Furnace Tube

The Heart of the Furnace

A tube furnace is designed around a central cylindrical chamber—the process tube. This tube is where the action happens.

It serves as the container for the material being heated (the sample) and maintains the controlled atmosphere required for the process, whether that's air, an inert gas, or a vacuum.

Separating Sample from Elements

The tube's primary function is to isolate the sample from the furnace's heating elements. This prevents contamination and allows for precise atmospheric control that would be impossible otherwise.

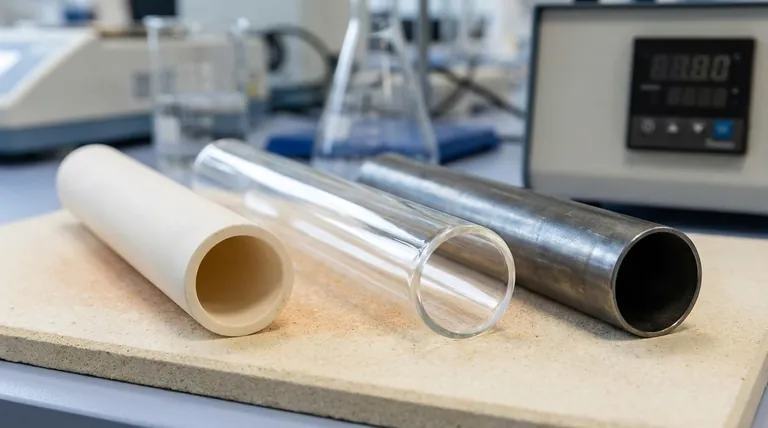

Common Tube Materials and Their Properties

Ceramic Tubes (Alumina)

High-purity alumina (Al2O3) is one of the most common materials for furnace tubes. It is a refractory ceramic known for its excellent performance at very high temperatures.

These tubes offer great thermal insulation and chemical stability, making them suitable for a wide range of high-temperature applications.

Quartz Tubes

Quartz is another popular choice, particularly for processes that require high chemical purity and thermal shock resistance at moderate temperatures (typically below 1200°C).

Its transparency also allows for visual observation of the sample during the heating process, which can be a significant advantage in certain research scenarios.

Metal Alloy Tubes

For specific applications like vacuum sintering, tubes are often made from imported, heat-resistant metal alloys.

These alloys are selected for their durability and ability to maintain structural integrity under high vacuum and high-temperature conditions without releasing volatiles that could contaminate the sample. They are often used with non-metallic inner liners to further ensure purity.

Factors That Determine Material Choice

Maximum Operating Temperature

The single most important factor is the required temperature. Quartz tubes are generally limited to around 1200°C, while certain high-purity alumina tubes can operate well above 1700°C.

Chemical Compatibility

The tube material must be chemically inert with respect to the sample and any process gasses used. An incompatible material can react with the sample, introducing impurities and invalidating the experiment.

Process Atmosphere

The intended atmosphere—air, inert gas (like argon), or high vacuum—heavily influences the material choice. For example, heat-resistant metal alloys are specifically engineered to perform in high-vacuum environments where ceramics might be less suitable.

Understanding the Trade-offs

Ceramics: Brittleness and Thermal Shock

The primary drawback of ceramic tubes like alumina is their brittleness. They are susceptible to cracking if heated or cooled too quickly (thermal shock) and must be handled with care to avoid mechanical stress.

Quartz: Temperature and Chemical Limitations

While excellent for many applications, quartz has a lower maximum operating temperature than alumina. It can also devitrify and become brittle if held at high temperatures for extended periods and may react with certain alkaline or basic compounds.

Metal Alloys: Cost and Potential Reactivity

Specialized metal alloy tubes are often more expensive than their ceramic or quartz counterparts. While designed for stability, some alloys can still react or off-gas at the highest end of their temperature range, which is why they are sometimes paired with protective inner liners.

Selecting the Right Tube for Your Application

Choosing the correct tube is a critical decision based on your specific experimental goals.

- If your primary focus is extreme temperature resistance (above 1200°C): A high-purity alumina ceramic tube is almost always the correct choice.

- If your primary focus is working under a high vacuum: A specialized heat-resistant metal alloy tube is specifically designed for this purpose.

- If your primary focus is high purity at moderate temperatures or visual monitoring: A quartz tube offers superior chemical inertness and clarity for these applications.

Ultimately, matching the tube material to the precise demands of your process is fundamental to successful and repeatable thermal processing.

Summary Table:

| Material | Max Temperature | Key Features | Best For |

|---|---|---|---|

| Alumina Ceramic | > 1700°C | High temp resistance, chemical stability | Extreme heat applications |

| Quartz | < 1200°C | High purity, thermal shock resistance, transparent | Visual monitoring, moderate temps |

| Metal Alloy | Varies by alloy | Vacuum compatibility, structural integrity | High-vacuum sintering |

Need help selecting the perfect tube furnace tube for your lab's specific requirements? KINTEK specializes in lab equipment and consumables, serving laboratory needs with expert guidance on high-temperature materials. Our team can help you match the ideal tube material—whether ceramic, quartz, or metal alloy—to your temperature, atmosphere, and purity goals. Contact us today to ensure your thermal processes are accurate, safe, and repeatable!

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What are the catalysts used in biomass conversion? A Guide to Optimizing Your Process

- Why is a tubular quartz reactor specifically selected for the reduction of NiO and NiCl2? Expert Material Insights

- What are the primary functions of a high-temperature tube furnace? Master EP-823 Steel Heat Treatment

- How do tube furnaces facilitate perovskite redox study? Master Thermochemical Hydrogen Research Environments

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?

- Why are quartz tube vacuum sealing and getters used during high-temperature annealing of stainless steel? Guard Purity

- What is the function of a high-temperature tube furnace? Simulate Nuclear Environments for Coating Tests

- Why is a tube furnace critical for Jatropha curcas bio-catalysts? Maximize Carbonization & Catalytic Performance