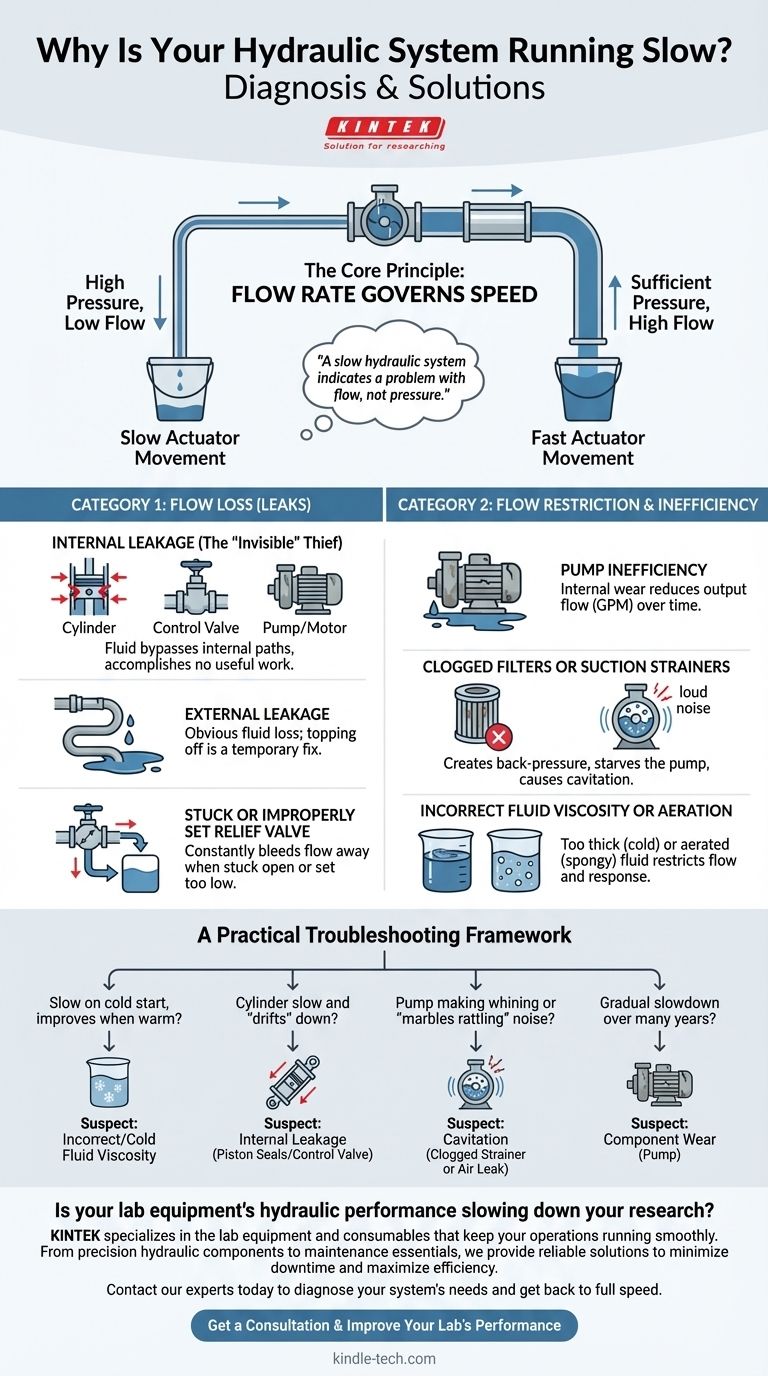

At its core, a slow hydraulic system is almost always a symptom of insufficient flow rate. While pressure provides the force to move a load, it is the volume of fluid moving through the system over time—the flow—that dictates the speed of your actuators, like cylinders and motors.

A slow hydraulic system indicates a problem with flow, not pressure. The core diagnostic challenge is to determine if the flow is being lost through leaks (internal or external) or if it's being restricted by blockages and inefficiency.

The Core Principle: Flow Rate Governs Speed

To diagnose a slow system, you must first understand the fundamental relationship between flow and speed.

Flow vs. Pressure

Think of your system like a garden hose. Flow rate (gallons per minute or GPM) is the amount of water coming out of the end. Pressure (pounds per square inch or PSI) is the force you feel when you put your thumb over the nozzle.

You can have high pressure but very little flow, which won't fill a bucket quickly. Similarly, a hydraulic system can build pressure against a blockage but have no movement. Speed is exclusively a function of getting the required volume of fluid to the actuator in a given time.

Diagnosing the Root Cause: Two Primary Categories

Every cause of a slow hydraulic system falls into one of two categories: the fluid isn't being delivered efficiently, or the fluid that is delivered is not being used correctly.

Category 1: Flow Loss (Leaks)

Flow loss means the fluid generated by the pump isn't reaching the actuator. It's being lost or diverted along the way.

Internal Leakage (The "Invisible" Thief)

This is the most common cause of a gradual slowdown in older equipment. Fluid leaks past worn seals inside components, accomplishing no useful work.

The primary culprits are worn piston seals in a cylinder, worn seals in a control valve, or excessive clearance in a worn pump or motor. The fluid bypasses its intended path and returns to the reservoir at a lower pressure.

External Leakage

This is the most obvious cause. If you see hydraulic fluid dripping or pooling, your system is losing the medium it needs to operate. Topping off the fluid is a temporary fix for the real problem: a failed hose, fitting, or seal.

A Stuck or Improperly Set Relief Valve

The pressure relief valve is a safety device that diverts excess flow back to the tank when pressure exceeds a set limit.

If this valve is stuck partially open or is set too low, it will constantly bleed flow away from the main circuit. The system will act as if it has a major internal leak, resulting in slow operation.

Category 2: Flow Restriction & Inefficiency

Flow restriction means the pump is working, but something is preventing the fluid from moving freely through the circuit.

Pump Inefficiency

As a pump wears, its internal tolerances increase. This causes more and more fluid to slip from the high-pressure outlet side back to the low-pressure inlet side.

The pump may still be able to build pressure, but its output flow (GPM) at that pressure will be significantly lower than when it was new. It's simply not producing the volume of flow required for proper speed.

Clogged Filters or Suction Strainers

A clogged filter on the return or pressure line creates back-pressure, forcing the pump to work harder and reducing overall system efficiency.

A clogged suction strainer is even more critical. It starves the pump of fluid, leading to cavitation—the formation and collapse of vapor bubbles. This not only causes severe damage to the pump but also introduces vapor into the fluid, making it "spongy" and causing slow, erratic actuator movement.

Incorrect Fluid Viscosity or Aeration

Hydraulic fluid that is too thick (high viscosity), often due to cold temperatures, will not flow easily. This can starve the pump and cause slow operation, especially on startup.

Aeration, or air entering the system (often from a leak on the suction side of the pump), makes the fluid compressible. Instead of moving a cylinder, the initial pressure just squeezes the air bubbles, resulting in a spongy and slow response.

Common Diagnostic Pitfalls to Avoid

Troubleshooting can be frustrating if you chase the wrong symptoms. Avoiding these common mistakes will save you significant time and resources.

Confusing Pressure with Flow

Never assume high pressure means a healthy system. A system can register maximum relief pressure simply because fluid is blocked and cannot flow. Always diagnose speed issues as flow problems.

Ignoring the Fluid

The hydraulic fluid is the lifeblood of the system. Always start by checking the fluid level and condition. Low, contaminated, or aerated fluid can mimic the symptoms of a major component failure.

Overlooking Simple Checks

Before assuming a pump or cylinder has failed, perform the simple checks. Ensure the engine or motor driving the pump is running at the correct speed. Check that all valves are in the correct position. Inspect for clogged filters.

A Practical Troubleshooting Framework

Use this logic to systematically identify the problem.

- If the system is slow only on cold start but improves as it warms up: Your primary suspect is incorrect or cold fluid with high viscosity.

- If a cylinder is slow and "drifts" down when holding a load: This strongly indicates internal leakage in the cylinder's piston seals or the associated control valve.

- If the system is slow and the pump is making a loud whining or "marbles rattling" noise: You are likely dealing with cavitation from a clogged suction strainer or aeration from an air leak on the suction line.

- If the slowdown has occurred gradually over many years of service: Suspect component wear, most likely in the pump, which is delivering a lower flow rate than its specification.

By approaching the problem methodically, you can move from symptom to cause and find the true source of the performance issue.

Summary Table:

| Category | Primary Cause | Common Symptoms |

|---|---|---|

| Flow Loss (Leaks) | Internal component wear, external leaks, stuck relief valve | Gradual slowdown, cylinder drift, low fluid level |

| Flow Restriction | Worn pump, clogged filters, incorrect fluid viscosity | Slow cold start, pump cavitation noise, spongy operation |

Is your lab equipment's hydraulic performance slowing down your research? KINTEK specializes in the lab equipment and consumables that keep your operations running smoothly. From precision hydraulic components to maintenance essentials, we provide reliable solutions to minimize downtime and maximize efficiency. Contact our experts today to diagnose your system's needs and get back to full speed.

Get a Consultation & Improve Your Lab's Performance

Visual Guide

Related Products

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- Manual Lab Heat Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- 30T 40T Split Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- How much force can a hydraulic press exert? Understanding its immense power and design limits.

- What is the purpose of using a laboratory hydraulic press for nanocomposites? Ensure Precise Material Characterization

- What role does a laboratory hydraulic hot press play in rice husk-based composite boards? Achieve Structural Density

- What is a heated hydraulic press used for? Essential Tool for Curing, Molding, and Laminating

- What technical conditions does a heated hydraulic press provide for PEO batteries? Optimize Solid-State Interfaces